+86 576 84086666+86 576 84086666

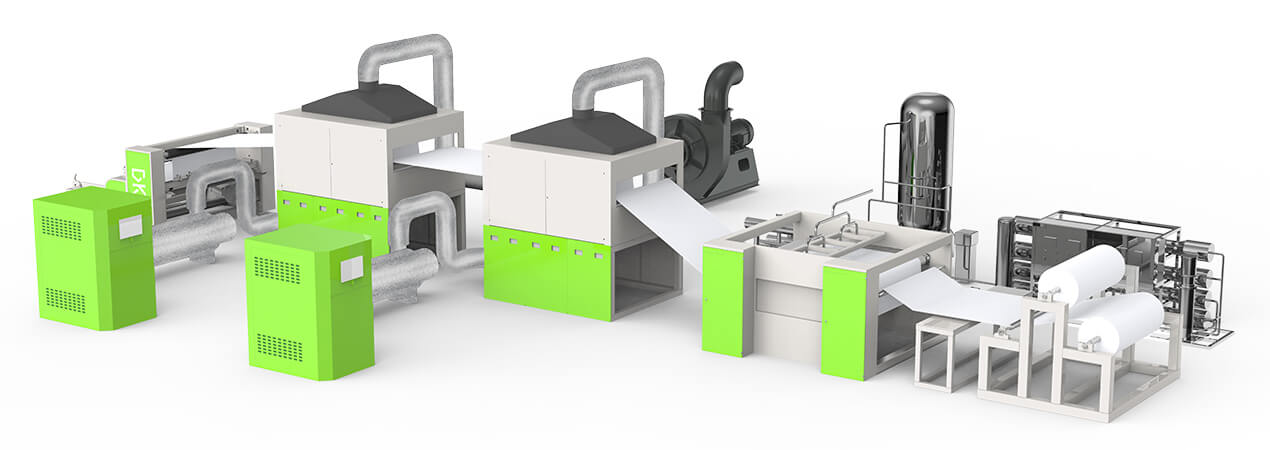

Melt Blown Production Line

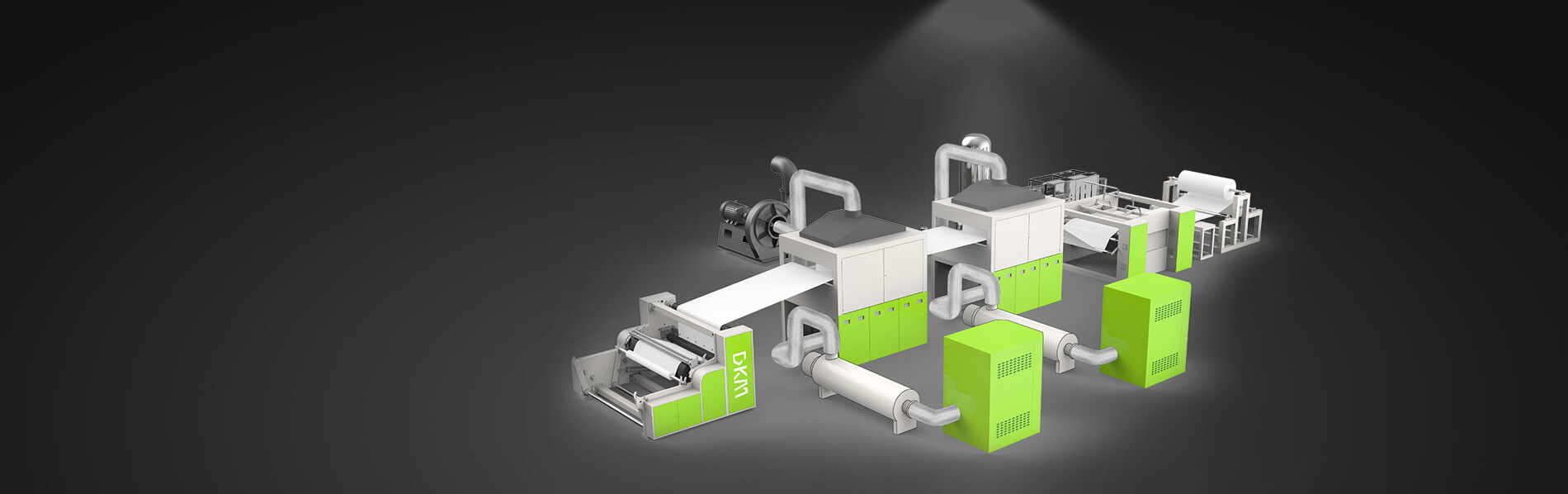

DKM Hydro-Charging Machinery

Making FFP2+ / KF94+ melt blown fabrics by DKM hydro-charging machinery, meet your high-end market of malt blown cloth. DKM offers the whole melt blown fabric production line with hydro-charging method as well to save your time and cost.And there is

complete one piece unit hydro-charging melt blown fabric line, saving much space.

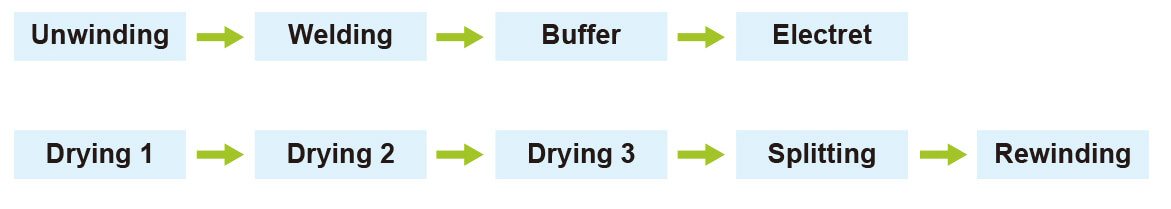

Hydro-Charging Method Process

The hydro-charging method makes the melt blown fabric more stable on electret, getting better permeability, strong adsorption and low resistance, which can achieve good filtration efficiency and meet the requirements of FFP2/FFP3 and other tests.

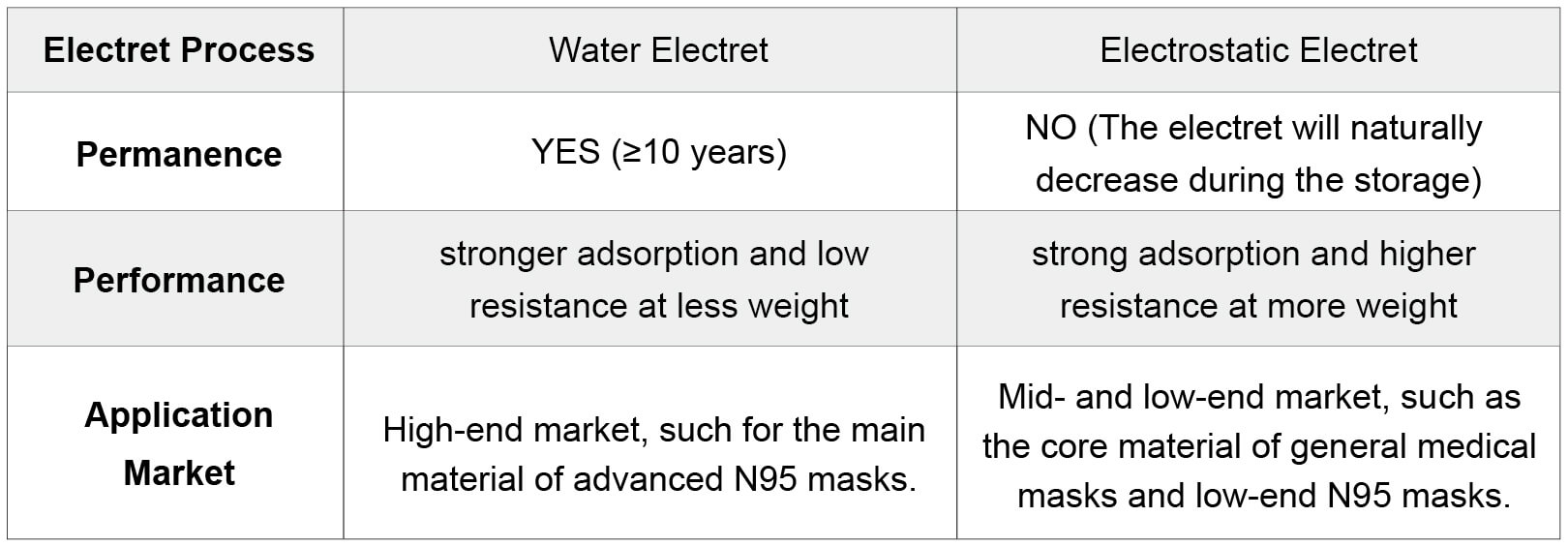

The Difference between Hydro-Charging Method Electret and Electrostatic Electret

DKM Hydro-Charging Method Machinery Nine Highlights

DKM will reply in 8 hours!

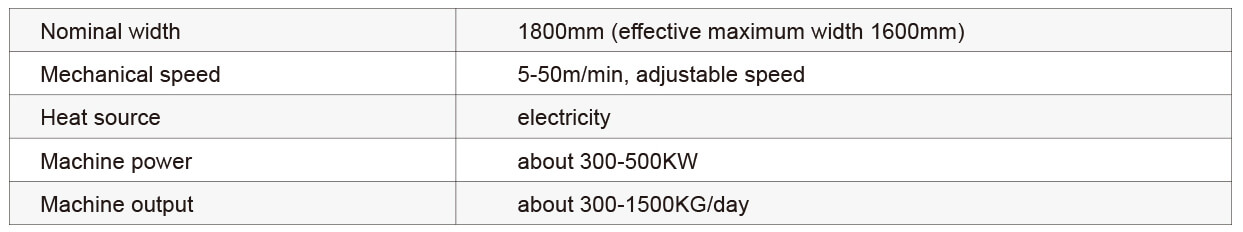

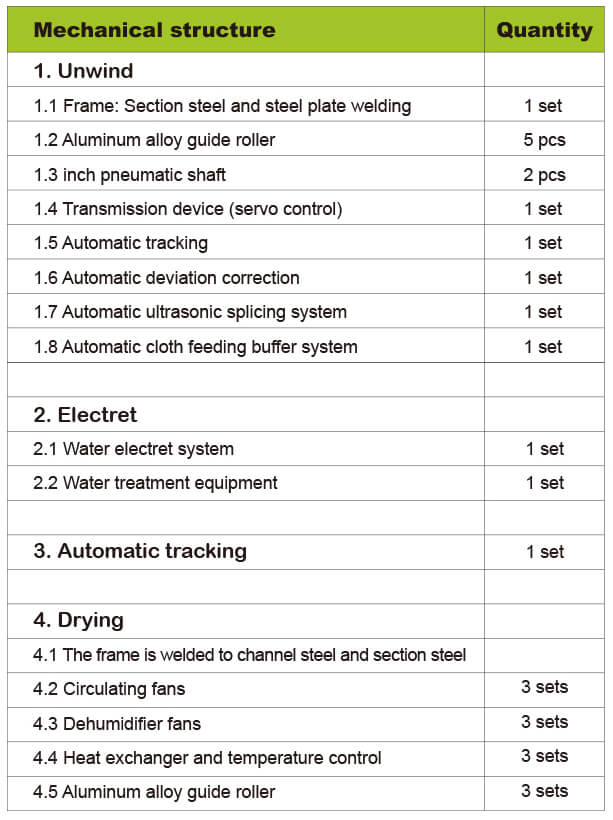

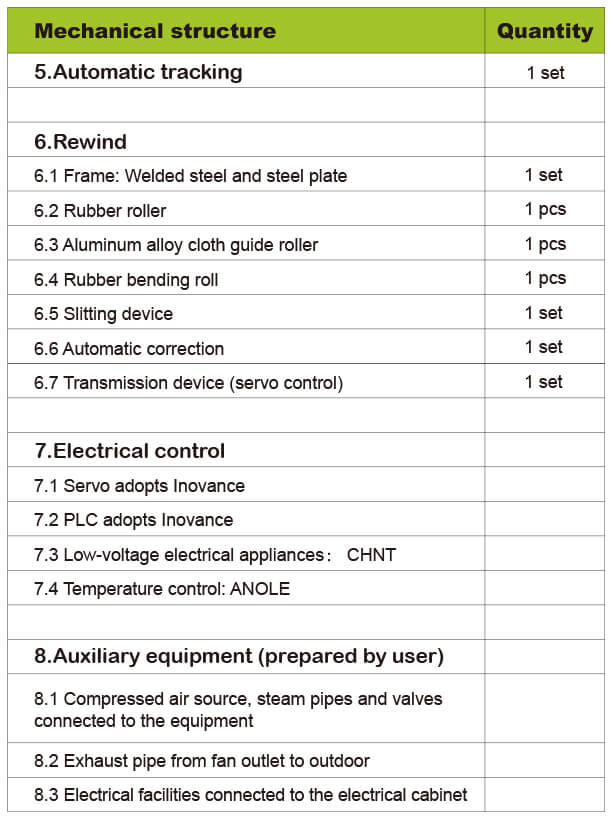

DKM Hydro-Charging Method Machinery Specification

For DKM1600 Hydro-Charging Method Melt Blown Fabric Production Line

DKM Service

DKM provides comprehensive service to meet the diversified demands and fast response ensure that customers could run the machinery well without unnecessary down time and finally produce high-end melt blown fabric efficiently. The expert service team and the other teams are always here for any support.

Get in touch with DKM for nonwoven production line solution or any questions.