Nonwoven Fabric Production System

The production of nonwoven fabrics takes place in several stages, and usually it’s about three stages: nonwoven fabric forming, bonding and further treatment. Here we are talked about the nonwoven fabric production system profile based on forming stage.

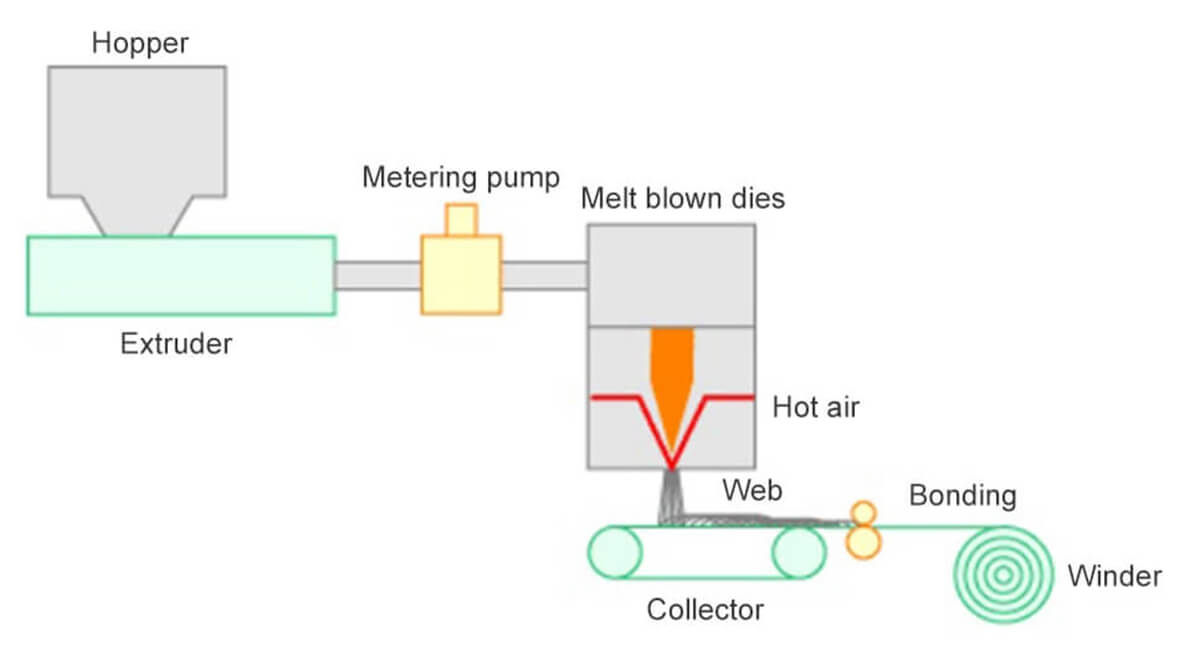

Meltblown Process

The melt-blown nonwovens are produced by extruding molten polypropylene (PP) through a meltblown mould to forming fibers under hot air assistant which flow toward to the collector and are cooled to form web.

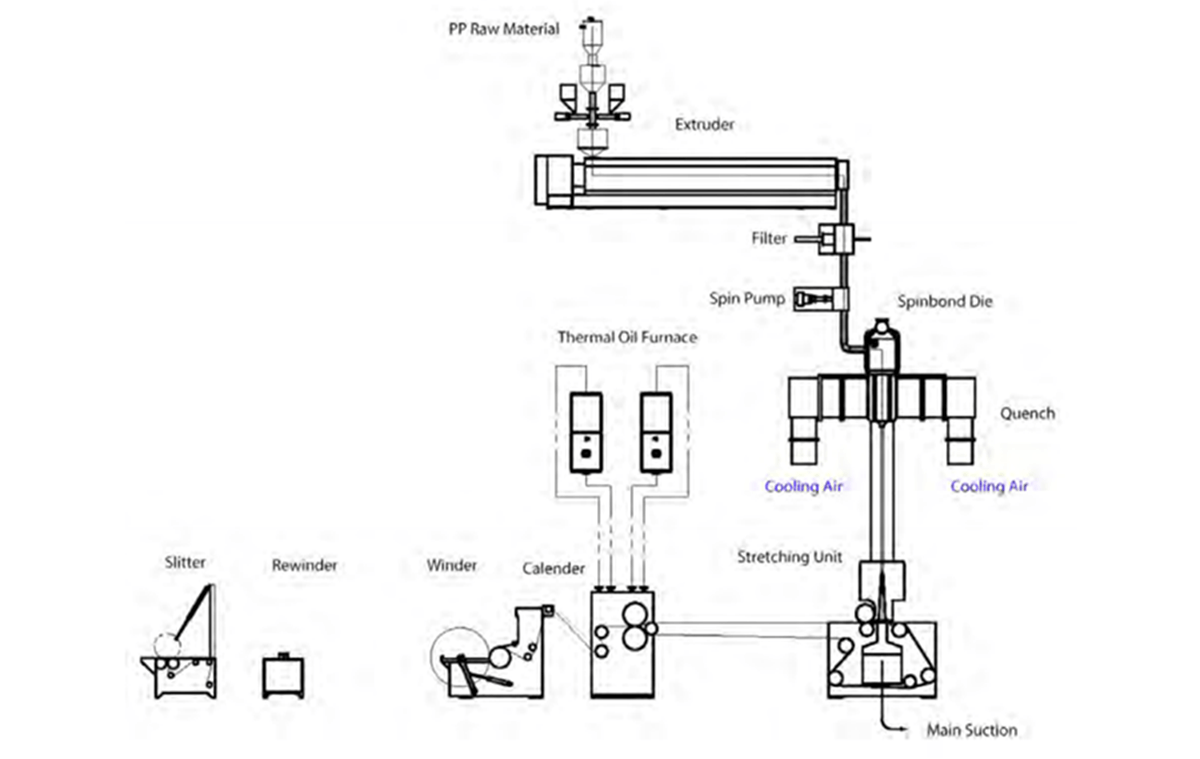

Spunbond Nonwoven Process

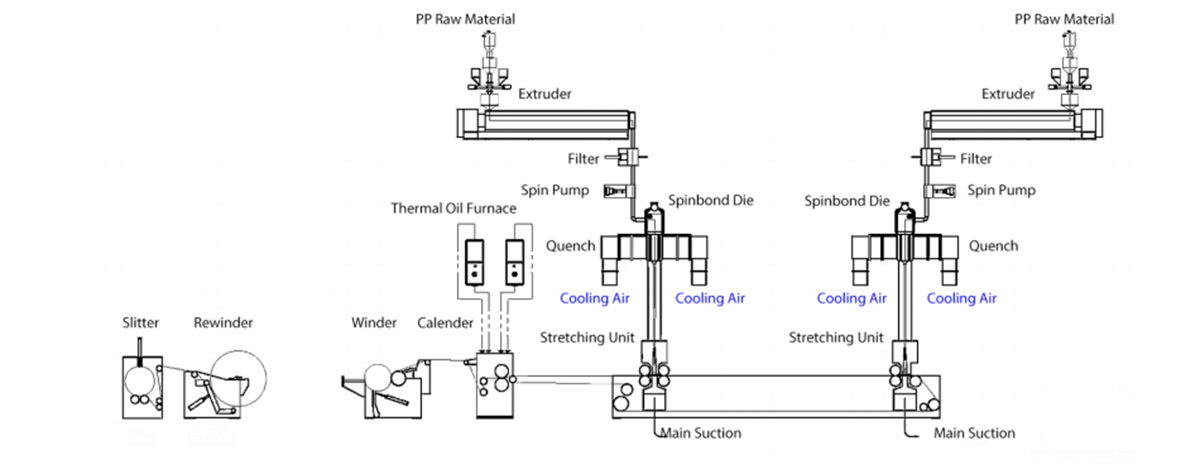

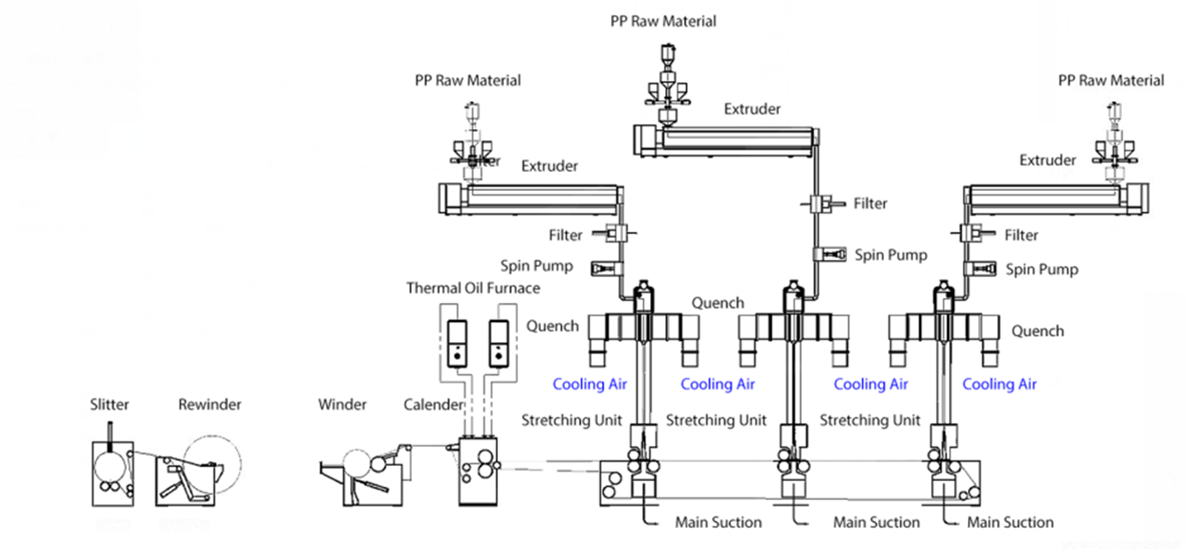

The spunbond nonwovens are made from the molten polymer extruded through a spinbond die: under the cooling air, spun filaments onto a collecting belt in a uniform random manner followed by bonding the fibers.

This process could be applied repeat at same time to meet the exact specification of spunbond nonwovens.

Spunbond Nonwoven Fabric (S)

Spunbond Nonwoven Fabric(SS)

Spunbond Nonwoven Fabric (SSS)

Spunmelt Nonwoven Process

Spunmelt nonwoven is made by the combined process of meltblown and spunbond, which are strong and offer the intrinsic benefits of fine fibers. And there are multiple combinations for meltblown and spunbond processes.

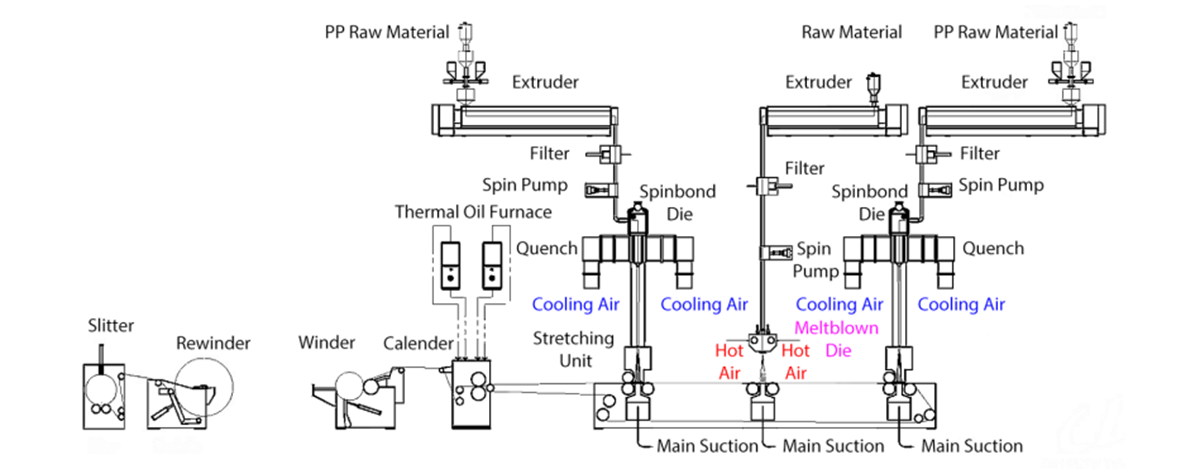

Spunmelt Nonwoven Fabric (SMS)

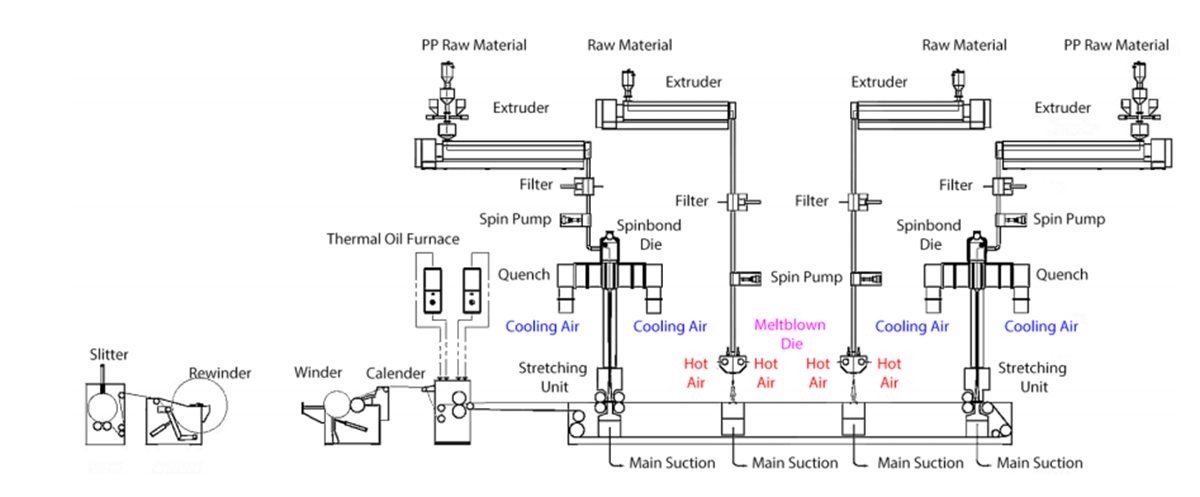

Spunmelt Nonwoven Fabric (SMMS)

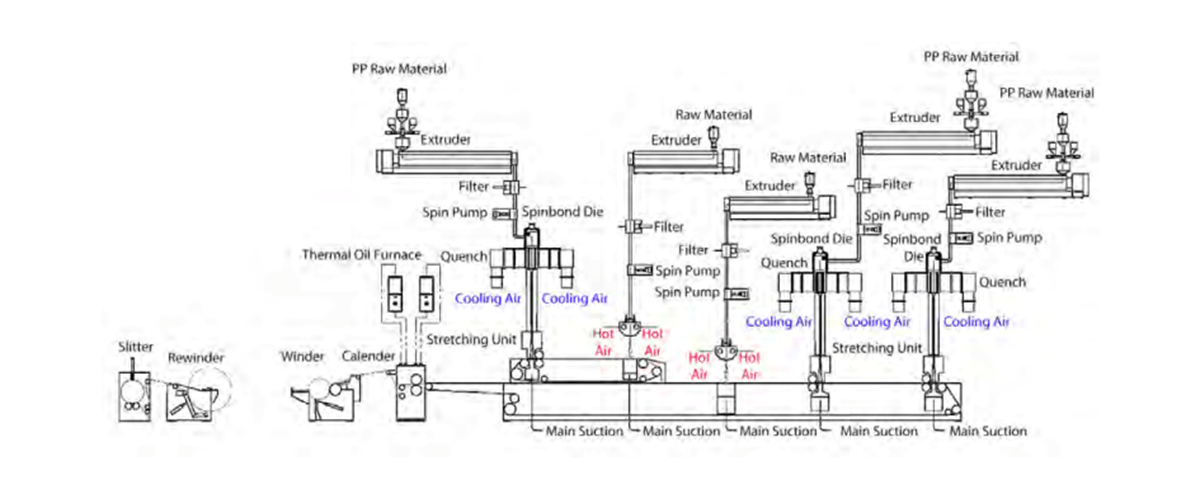

Spunmelt Nonwoven Fabric (SSMMS)

Get in touch with us to find the best solution for your Nonwoven Fabric Production System.