DKM Nonwoven Fabric Technology focus on offering you with various kinds of Spunbond Non Woven Fabric Production Lines,especially S, SS and SSS Spunbond Nonwoven Lines. At present, DKM supplies models of spunbond non woven lines with DKM-2400mm, DKM-3200mm. DKM Spunbond Lines are sold all over the world. We have set up agency service office in many countries, like Janpan, Korea ... And have been seeking to establish more national agent centers.

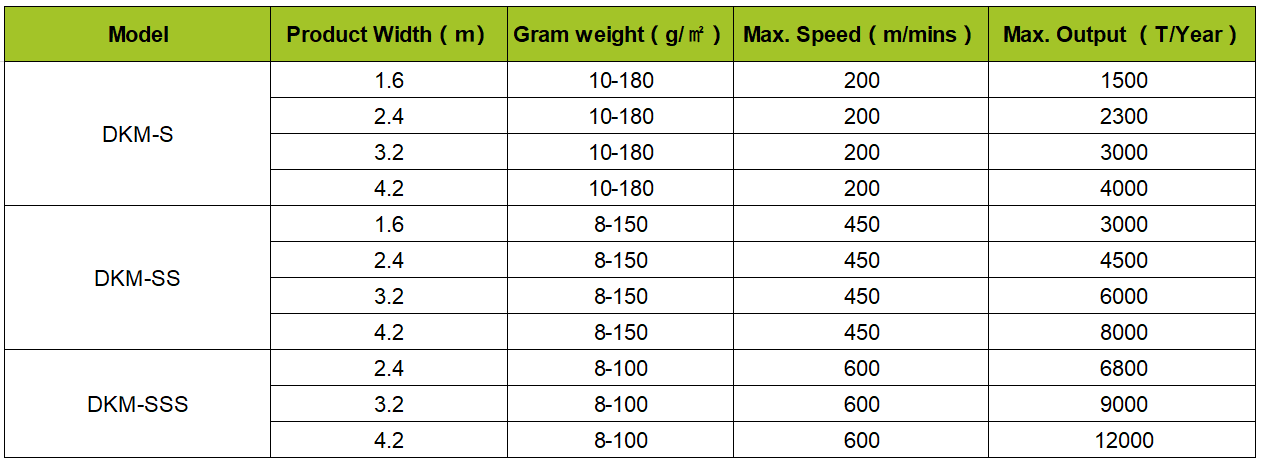

For DKM-2400, DKM-3200mm S, SS, SSS spunbond production lines,

The weight range of manufacture of fabric is in 10-180g/m2;

The speed is from 150-450m/min;

Capacity in 2300Tons-10000Tons/year.

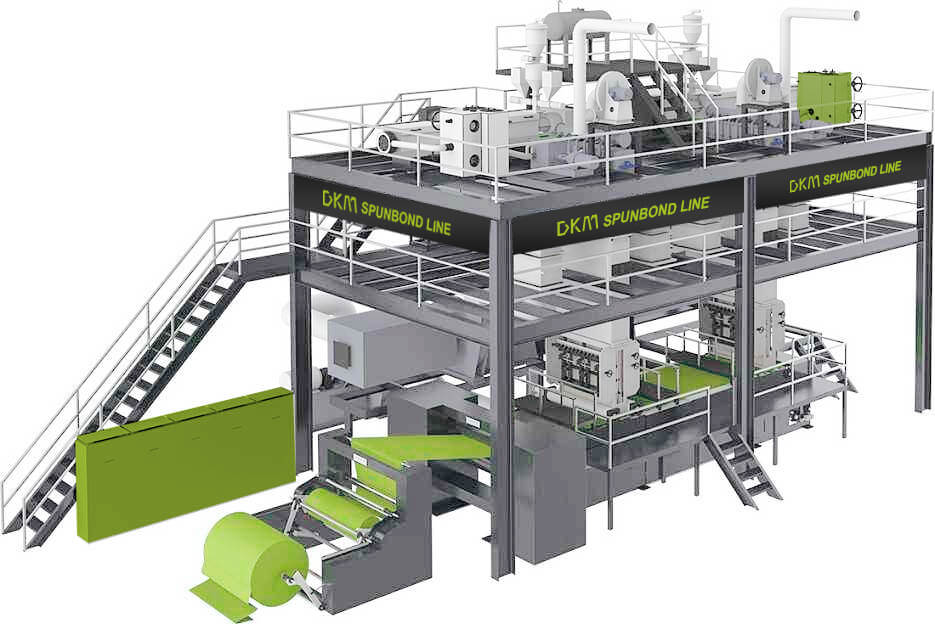

DKM Spunbond Non Woven Production Lines Highlights

It is not difficult to manufacture and provide spunbond nonwoven lines, but for DKM team, our original intention and ultimate goal is to provide customers with high-quality, efficient and high-quality production lines.

After our optimization of spunbonded non-woven production line, the customer operation is simple, convenient, easy to start, quickly put into production.

Through the in-depth research and analysis of our DKM technical team, the design of DKM air duct adopts the common slit type overall draft design to ensure the average laying of fiber mesh, the fiber fineness reaches about 3 Dan, and the vertical and horizontal strength of the product reaches or exceeds the national standard.

Equipped with advanced touch screen control, automatic tracking, over temperature and overpressure alarm system. The rolling mill adopts direct active power, hard tooth surface reducer and high stability universal coupling drive. The bearing adopts oil cooling over temperature and oil shortage alarm system. The roller surface adopts peripheral drilling technology to ensure the overall temperature difference. Advanced foreign design is introduced into the box body, and the fluid distribution is uniform to ensure that the waste products are not broken from time to time, so as to maximize the qualified rate of products.

DKM team not only offer you with high quality S, SS and SSS spunbond nonwoven lines, but also timely and efficient service. We own strong engineer and service department who can supply customers with perfect and systematic training, including the installation and adjustment, training. Normally, it takes 5-7 days of installation, 5 days for adjustment, and 5-10 days for training. You can also arrange your engineer to DKM for study and training.

Detail Specification

The actual parameters are subject to the contract.