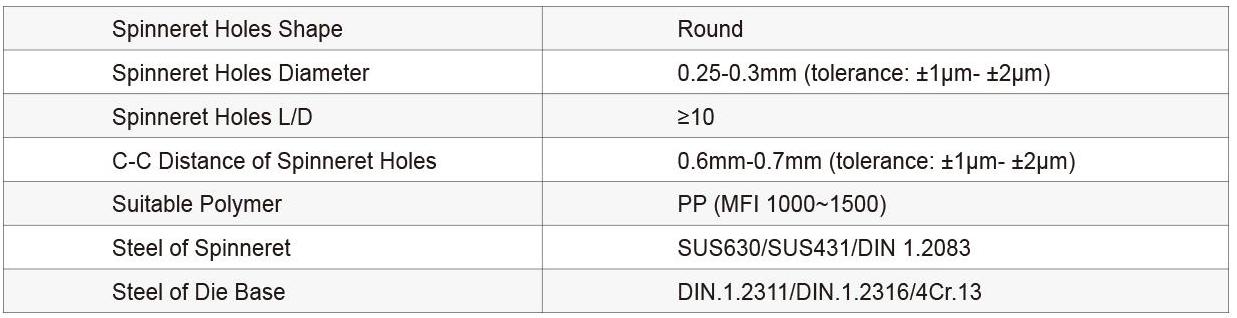

DKM experienced know-how of melt blown process ensures the high fabric quality with PFE at least 98% NaCI at flow rate 85L.

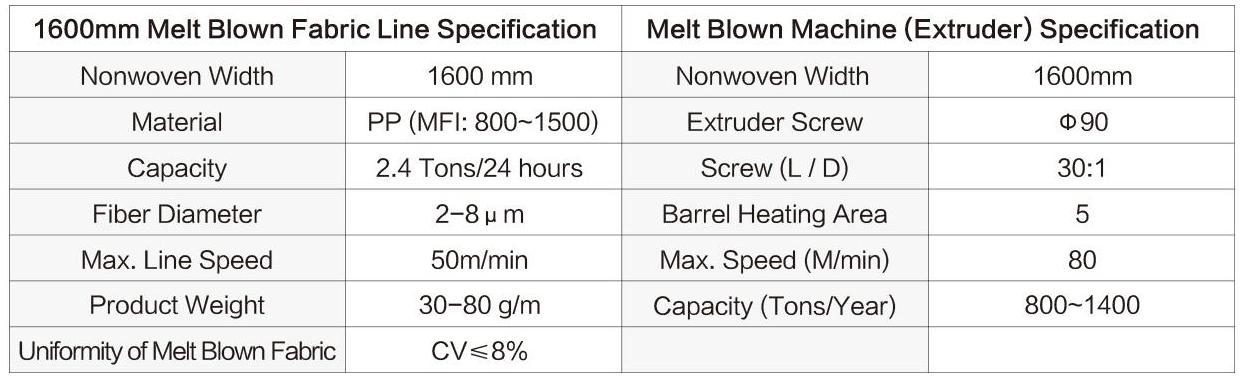

Two beam melt blown machine achieves production capacity of 2.4 Tons/24 hours.

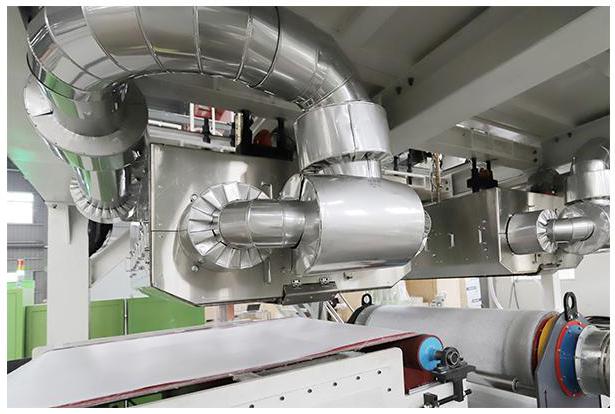

The overall line is designed based on the principle of ergonomics that guarantee the suitable layout for less workshop land covering.

a.One-button start and stop some heating area of extrusion.

b.PID control heating temperature, more precision.

c.The fan is controlled by frequency conversion, and the computer displays the fan speed, which is very convenient for customers to adjust the air volume by smart touch screen.

d.PID intelligent control pressure before and after filtration, easy for workers’ commissioning.

e.Sensor detection for wind pressure and smart adjustment on screen

DKM 1600mm MM Melt Blown Nonwoven Production Line, save your time and cost! Welcome to contact us for details.