We specialize in the plastic syringe production line supply, provide turnkey engineering and customized turnkey molding solution for syringe production line from A-Z service, including syringe mould, injection molding machine, assembly machine, printing machine, other auxiliary machines installation and engineer training work etc. DKM team would recommend the most suitable syringe production line equips base on the customer syringe annual/monthly production quantity.

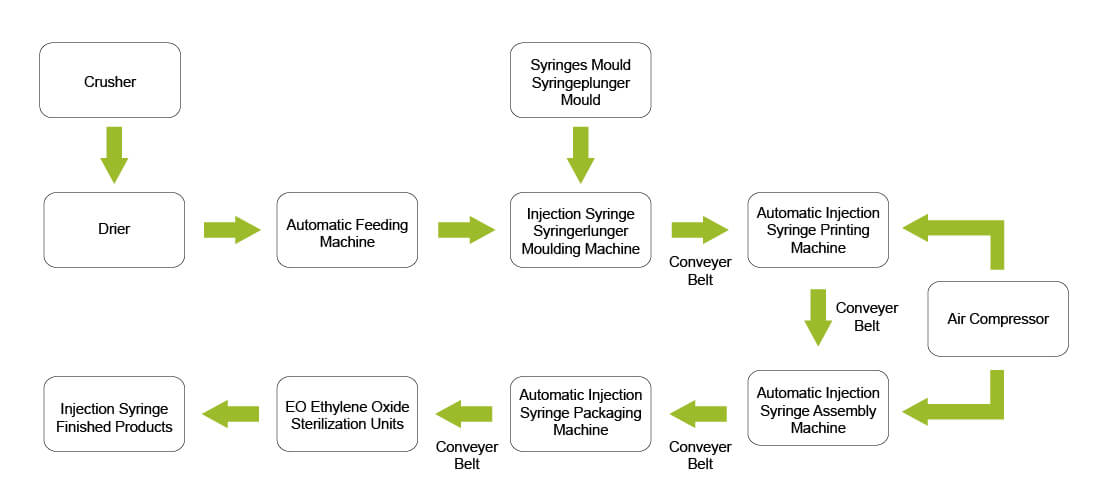

Syringe Injection Process

DKM offers customer turnkey disposable syringe production line solution, including product design research and innovation, molds design and mold flow analysis, molds development, the whole syringe production line equipment, after sales installment & training service. With more than 25 years research and medical syringe production line experience, we offer customer high quality, high precision medical molds.

- syringe mold (syringe plunger mold, syringe mold, syringe gasket mold)

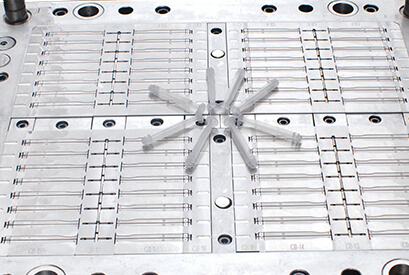

The S136 stainless steel provided by ASSAB is used to insert the core and cavity into the die base. The same parts in the die are interchangeable

Syringe mold could make with 16/24/32/48/64…128 cavities, we would design the most balance runner system for the syringe barrel, plunger and gasket molding. Sometime customer would directly purchase the gasket from the market because the gasket could be made by other molding process except the injection molding.

- plastic injection molding machine

For Plastic syringe production Line, high-speed injection machines are usually required. DKM Syringe Lines-Dakumar team provide hybrid type high speed injection molding machine which special using for the medical syringe production. Which is helpful to improve machine performance, speed up machine cycle time and improve efficiency, especially suitable for high-precision and high-consumption products

- injection molding machine accessories, such as auto loaders, dryers, chillers, air compressor ...

Syringe Assembly Line Process

- We undertake all kinds of syringe assembly equips, including ordinary type, 2 pcs syringe, self-destruction, insulin and safety self-destruction etc.

- Equipment assembly speed design in 1000-15000pcs/hour

- Equip for automatic assembly, detection, reject in qualified product and other functions.

- Centrifugal type feeding mechanism, low noise and good stability.

- The specified high-end configuration, clear inspection standard.

Syringe Packing Line Process

- Barrel、plunger、gasket、needle four parts assembly;

- The machine adopts 304 stainless steel material, and MC reinforced nylon etc.;

- PLC circuit system, and automatic detection system, imperfect products will be eliminated by machine;

- Material Feeding: centrifugal + Vibration plate

- It can be used in 100,000-degree purification workshop.

Syringe Printing Line Process

- Printing and spray oil;

- 304 stainless steel;

- PLC electronic control;

- Low noise and high speed;

- It can be used in 100,000-degree purification workshop.

Syringe Sterilization Process

Epoxy ethane is the main low-temperature sterilization method at present. The sterilization procedure of epoxy ethane shall include preheating, prewetting, vacuum-pumping, gasification of epoxy ethane to a predetermined concentration, maintenance of sterilization time, removal of ethylene oxide gas in the sterilization cabinet, and analysis to remove the residue of ethylene oxide in the sterilized articles. The epoxy ethane sterilizer must be placed in a well-ventilated place and should not be placed near the source of fire. To facilitate maintenance and regular maintenance, each side of the ethylene oxide sterilizer (including the upper part) should be reserved with a space of 51cm.Special exhaust pipes should be installed and completely isolated from other exhaust pipes in the building.

Below is the process how the syringe parts production could have clear view.

1. Work out the budget of starting the molding line, including necessary equipment: molds, machines, auxiliary equipment and tools you need.

2. Guide you with our professional support and experience during the detail of set up plant.

3. Offer all the detail drawings and equipment list, engineering service, training to you with our best service.

4. Give you all the best quality and you can come to see the turnkey plant running in SINO before shipping.

5. Offer 24 hours online service, supply best solution at the first time.

We are a manufacturing enterprise integrating scientific research, development, manufacturing, marketing and after-sales service. DKM syringe production line provides a full range of turnkey molding solutions for customized syringe production equipment and corresponding auxiliary assembly and packaging equipment. Till now, we have provided more than 20 sets of plastic syringe production line equipment for different countries. DKM provide sophisticated manufacturing and processing equipment; Perfect testing equipment and management system. We are serious support customers with advanced technology and good products in line with the requirements of GMP. Welcome to our DKM- We will do our best guide you and assist you put into scientific production and launch the market in sooner time, to be your money printer.