With a large demand increasing in the packaging market field, especially the thin wall container after the epidemic, now more and more plastic factories are expending the production line of plastic thin wall containers. So the competition become more and more fiercely, the investors minimizing packaging weight win the production line plastic containers in the market. Especially after the epidemic, more and more consumers use take-away thin wall container for the food from the restaurant. So now it is a good opportunity to establish the thin wall container production line.

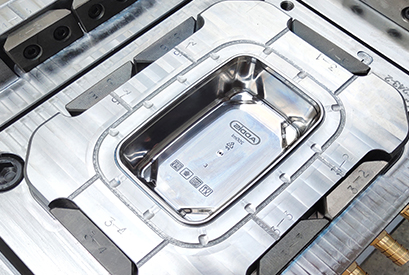

In the packaging industry field need to create the minimum packaging weight while complying with ever more stringent food and consumer safety regulations. Which includes both recycling and raw materials, is becoming more and more important for the long-term growth of the packaging industry. With this aim, our R&D team analyzes the material and mould flow analysis; we manufacture high quality and less weight of the production line of thin wall container.

We integrate researching and develop in manufacturing thin wall container mould as well as thin wall container machine, we can supply different various kinds of thin wall container lines, such as:

500ml square thin wall container molding production line

500ml round thin wall container molding production line

750ml square thin wall container molding production line

750ml round thin wall container molding production line

1000ml square thin wall container molding production line

1000ml round thin wall container molding production line

etc.

We have a design department with many professional designers, who have many years of experience in design thin wall injection molding machines, especially for high speed injection machines. We use high thin wall injection molding technologies to find a solution for our clients.

Compared with normal injection machine, our thin wall high speed injection machine has bellow advantages:

1. High Speed

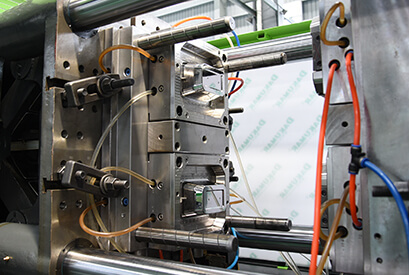

Machine adopts high precision single cylinder injection system, especially suitable for high speed injection with low-inertia and high response speed. Thin wall high speed injection machine can produce thin wall products more efficiency and production cycle time is shorter.

2. High Energy Saving

Machine with high response servo system, machine output according to actual need, no overflow no waste. It can save power around 30-70%.Compared with traditional machines, we use servo motor to save energy consumption and at the same time control the position more precise.

3. High Safety

Thin wall high speed injection machine is with mechanical, hydraulic, electrical triple protection.

Security module independent control will be ensure that there is no mistake of machine closing, injection, charging, nozzle forward to avoid any accident.

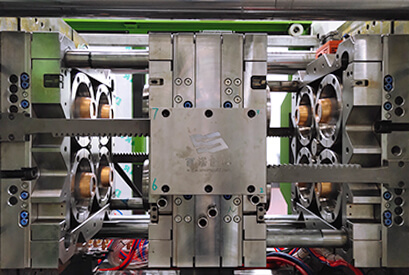

The high speed injection machine is specially developed for high speed and high precision injection molding. The machine frames, clamping units are much stronger for high speed injection. And they are also very stable for high pressure working.

This kinds of high speed injection machine take advantages of high injection speed, shorten running cycle time, work more efficiency and especially suitable for ultrathin, precious and complicated products.

For the high-efficiency production requirements of such food containers, DKM high-speed special thin-wall plastic container production line achieves dual guarantee on output and stability, making production more stable, clean, efficient, and low energy consumption. If you want to start any new project about the thin wall container or thin wall bucket production line, please feel free to contact us, DKM container team will offer you the best solution for your high speed thin wall turnkey production line.