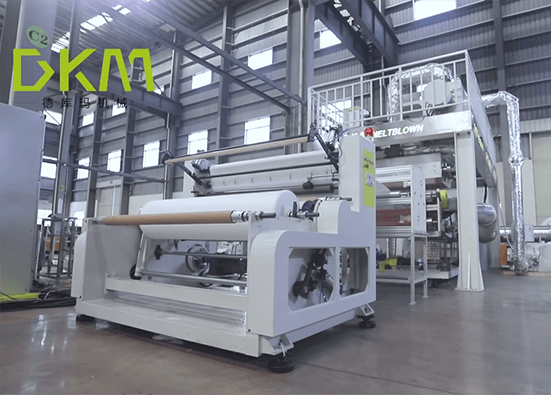

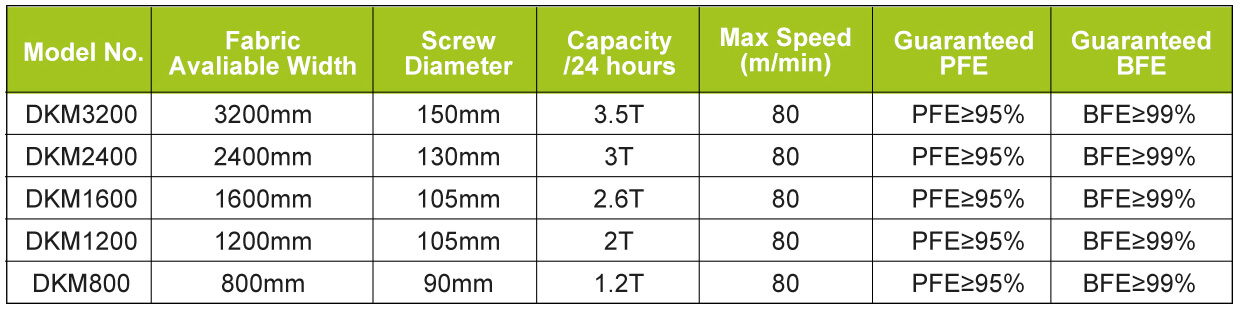

DKM has been providing meltblown lines to meet the rigorous demands of the KN95 mask non-woven fabric production. We strive to offer one stop solution of the most efficient meltblown fabric production lines for high quality PFE & BFE ≥96% with comprehensive service, save your time and money on starting the new meltblown non-woven fabric production business!

DKM-1600 Meltblown Line Profile

Power Requirement: 380V/3Phase/50HZ

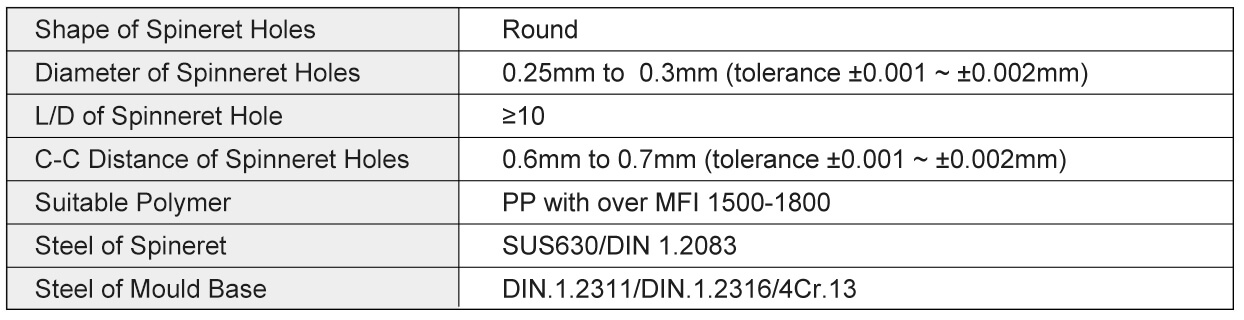

Material: PP chip (MFI 1500-1800)

Available Fabric Width: 1600 mm

Product Weight: 25-150g/m2

Capacity: 1-1.4 Tons per 24 hours (for KN95 and above)

Reliable Production Capacity

Stable and efficient production proved:Daily output of more than 1-1.4 tons

Easy Operation & Maintenance

We ensure that the line operation is easier, And was design for easy maintenance.

Save Floor Space

Considering the workshop layout, DKM meltblown line is “Z” type to save the whole line floor occupation.

Energy Saving

DKM extruders apply the servo system, saving much energy based on accurate speed torque.

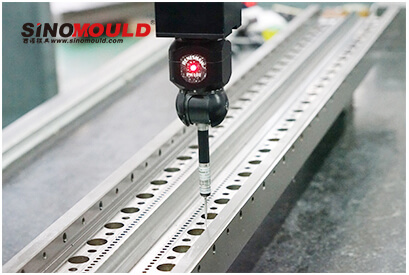

Live Production Control

DKM lines set precision pressure and temperature sensors at key processes to monitor production in real time.

DKM offers a whole solution designed to improve productivity of customers’ meltblown non-woven fabric production, with a strict focus on quality in order to meet high requirement of KN95 and above.

DKM90/30 Single Screw Extruder

Air Heating System

Winder

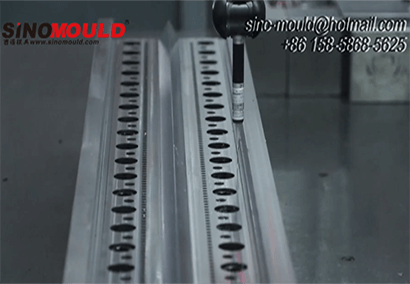

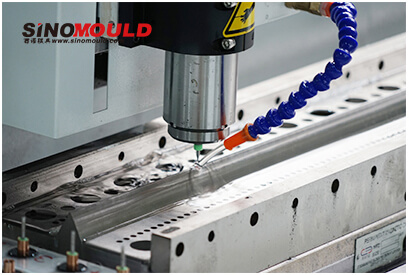

Meltblown Mould

Fibers Collector

Centralized Electrical Control System

Metering Pump

Electrostatic Electret Processor

Other auxiliary equipment and tools

Guide on installation and commissioning of equipment.

Foundation installation drawing supported.

DKM could help provide the drawing and guide for customers do the preparation for further production line installation.

Regular Research

DKM team would follow the whole line running regularly to help provide the timely support and guide to keep the line operating in ike-new condition.

DKM PP meltblown non-woven fabric production lines is optimized to deliver the high quality mask fabric. Contact us now to get yours!