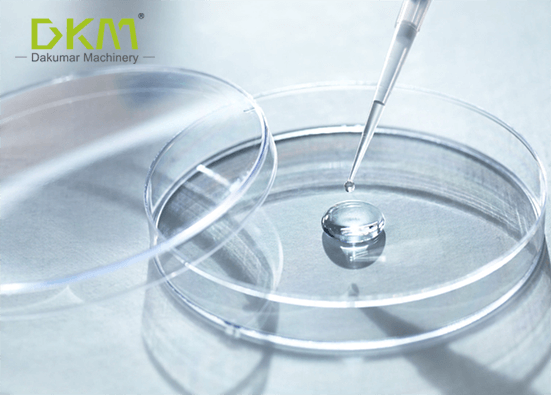

DKM offers one stop solution for medical part injection molding meeting the strict demands of the medical industry, thanks to its 20+ years of experience on plastic injection molding technology for medical applications. The demands which may include high quality optical finishes, intricate mold solution, high precision, high product consistency, high quality monitoring, more yield and less scrap. The complete medical part solution offered to save your time and cost, gets your product to market first!

Optimal Part Design

DKM assists in plastic medical part design and prototype development, our engineers are experts at designing parts for manufacturability. DKM maintains a timely communication with medical industry, so we know well about the customers’ demand and it helps us do excellent on part design.

Nowadays, the medical part innovation cycles are shrinking, so the time to market is critical. And DKM excellent medical part design ability could do it quicker to help customers shorten the time.

Medial Part Special Features

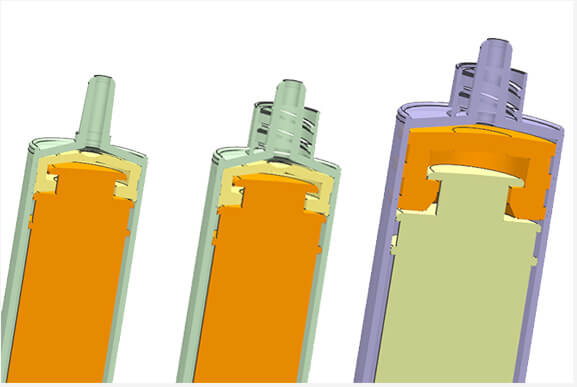

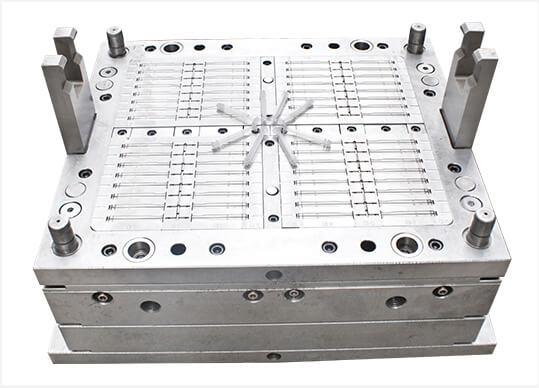

Superior Mould Design & Tooling

Based on optimal part design, the mould design could be done well to improve the productivity and guarantee the part quality under the expert team. We pay attention on the mould actions, cooling and maintenance for efficient production.

As the high requirement of the precision of the medical part, the mould tooling would keep the rigorous tolerance control, which could be up to +/- 0.05mm

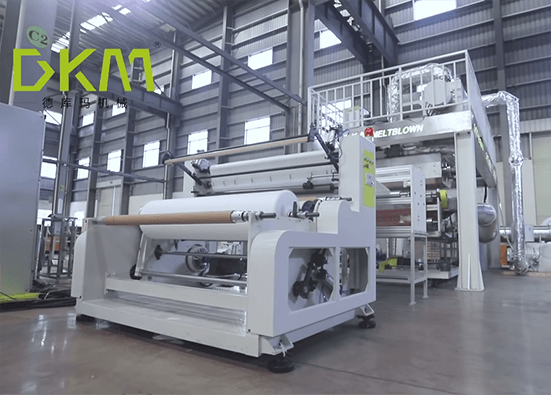

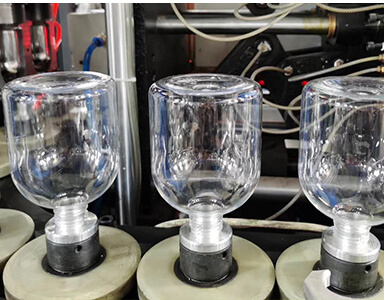

Expertise Medical Molding System

DKM supplies the integrated medical part molding system deliver quality parts, including injection molding system, automation system, in-line inspection system, packaging system and other further process system, which is customized according to the requirements of customers.

Extensive Customer Service & Support

To guarantee and optimize the efficient and stable running of medical part molding line, you could get the comprehensive, value-added service and support from initial part design and development, design for manufacturability, material selection to factory planning, the line solution met demands, technical support and training.

Now we have service centers in more than 40 countries and area for local support, and we are improving it to be more responsive, which helps on less downtime and keeping medical molding lines running in like-new condition.

DKM Medical Part Molding Solution Range

DKM has been offering one stop solution to meet the high demands of the medical appliance, including diagnostics, wound management, vascular, disposables, infection prevention… We are engaged in providing the precision, efficient and cost-saving solution.