Dear DKM Customers:

First of all, we would like to express our sincere gratitude for your trust in our company. As a manufacturer of equipment and molds specializing in the injection molding industry for disposable syringes, we have successfully delivered hundreds of syringe injection molding production lines. To meet the needs of more customers, we have expanded our focus from supplying injection molding solutions to researching back-end production line equipment, including syringe printing equipment, assembly equipment, packaging equipment, and sterilization equipment. We can also provide the service of establishing medical production facilities for clients.

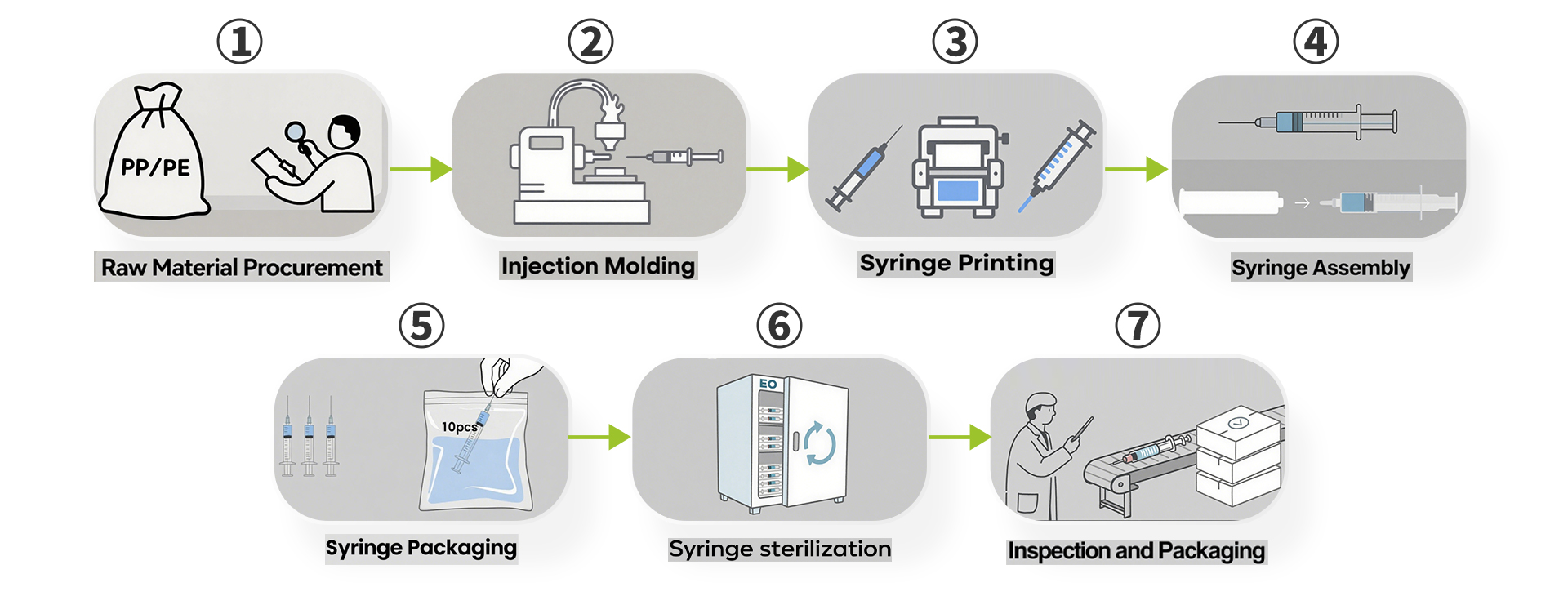

Currently, we have already established a comprehensive and reliable supply chain system. We understand that for customers just beginning to explore this project, it may be challenging to get comprehensive, professional production line knowledge and to get a reliable supplier. The DKM team always adheres to the principle of creating the greatest value for customers. Below, we will present a detailed overview of the syringe production process flowchart, allowing customers to understand the most common production processes in the market from this page.

- STEP 1 Raw Material Procurement

Components of a disposable syringe: A disposable syringe consists of a syringe barrel, plunger, gasket, needle hub, needle, and needle cap. The most common production approach for customers is to manufacture the syringe barrels and plungers themselves, while purchasing the gaskets and needle parts from the market initially. Once customers have established mature production experience and stable business operations, they may begin considering in-house production of needle caps and needle hubs. However, for first-time customers entering the production line, to reduce costs and focus production efforts, that solution is easier to adopt, with some components produced in-house and others purchased from the market.

When considering raw material costs, customers should select high-quality medical-grade PP plastic for syringe barrel and plunger production.

- STEP 2 Injection Molding

The injection molding process involves high-precision injection molding machines, molds, and auxiliary equipment. DKM is familiar with international standards for medical syringe products, which impose strict requirements on product tolerances, appearance, and functionality. The precision of equipment and molds plays a critical role in this process. To deliver high-quality products, every step must be rigorously controlled. A perfect design, precise processing, mature equipment, and a professional team are essential for successfully launching a syringe project.

- STEP 3 Syringe Printing

Each barrel must be printed with clear markings using printing equipment. A high-quality printing machine ensures that the printed content remains durable and precise. Our company collaborates with high-quality printing suppliers to provide reliable printing technology, ensuring that the printing on each syringe consistently meets stringent standards.

- STEP 4 Syringe Assembly

DKM uses a fully automated assembly line and can be equipped with visual inspection equipment to ensure proper assembly and full functionality.

- STEP 5 Syringe Packaging

DKM uses a fully automated packaging line, with each packaging label clearly marked with the syringe’s batch number, model, production date, and other detailed information, making it convenient for medical personnel to use the product correctly and ensuring traceability.

- STEP 6 Syringe sterilization

Ethylene oxide sterilization is widely recognized as the most efficient and reliable sterilization method for syringes. This ensures thorough sterilization without affecting the appearance or properties of the finished syringes. Standard models range from 5 to 60 cubic meters. Since the sterilization process takes 12 to 16 hours to achieve optimal results. Therefore, it is better to have our professional sales team customize a solution based on your production capacity requirements.

- STEP 7 Inspection and Packaging

All syringes undergo rigorous quality inspections before being packaged and delivered. Visual inspection equipment can be used to monitor the entire production process, or batch sampling inspections can be conducted to identify issues promptly and address them.

We hope the above information is helpful for your understanding of syringe production. If you have any questions or require further assistance, please feel free to contact us. We look forward to a long-term partnership with you and are committed to providing the most professional support for your medical business.