Disposable Syringe Production Line

DKM is a Chinese leading manufacturer of fully-automated and turnkey disposable syringe production lines. Our production line solutions include medical high precision molds, injection molding machines, syringe printing machines, syringe assembling machines, syringe packaging machines, and syringe sterilizing equipment. Focusing on improving production line performance and product quality, we have successfully provided more than 20 turnkey syringe projects for different countries such as Russia, Uzbekistan, Mexico, and so on.

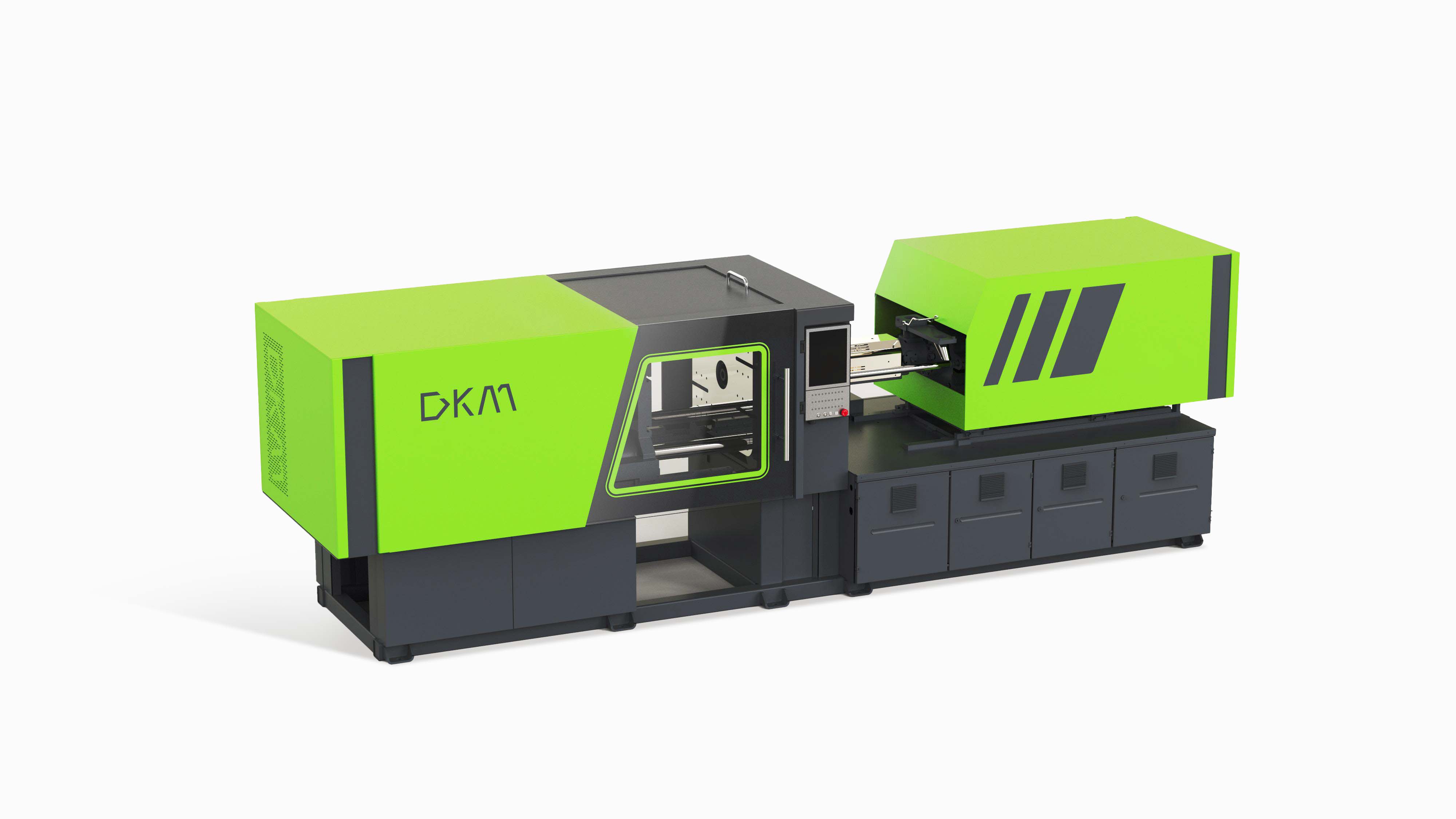

Syringe Injection Molding System

DKM has been focusing on the research and development of syringe injection molding lines for over decades years, accumulating much technical experience. This expertise enables us to provide one-stop, comprehensive solutions for the construction of automated and intelligent factories for medical syringes worldwide.