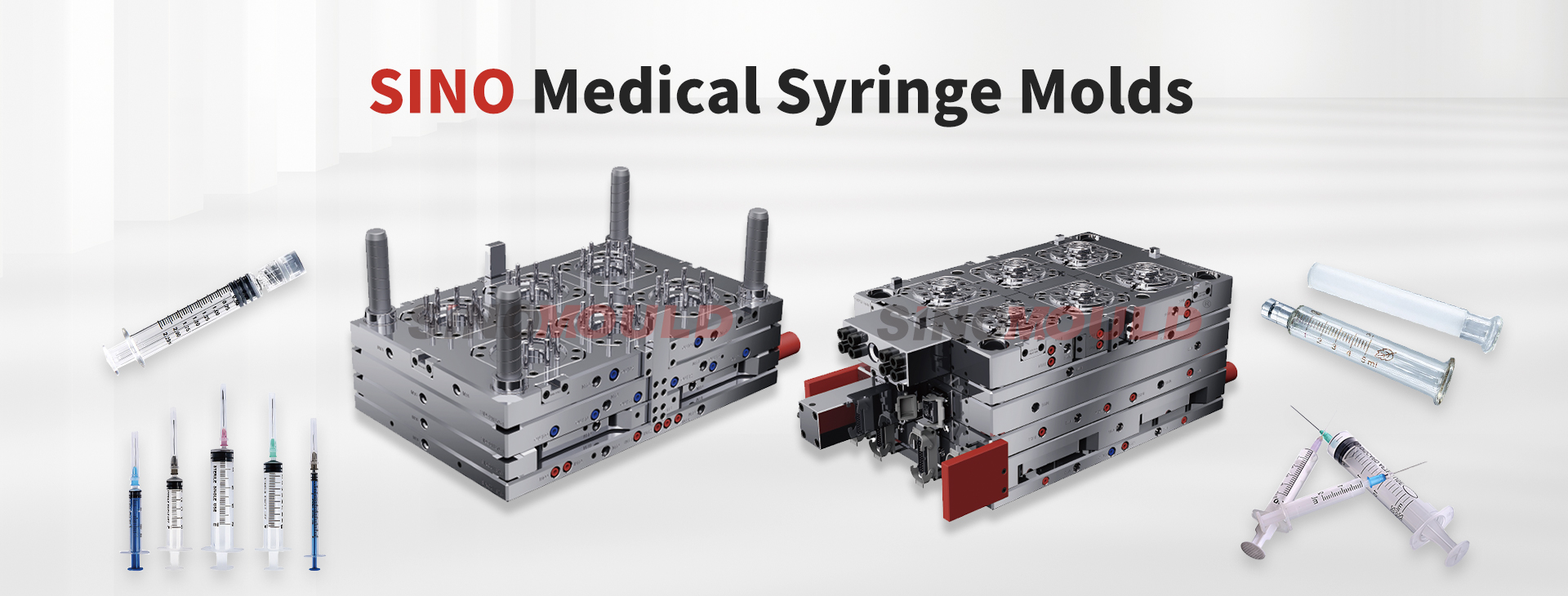

Syringe Molds

The syringe molds is powered by SINO Mould. SINO Mould has over 20 years of experience in the R&D and manufacturing of disposable syringe molds. The syringe mold series includes barrel molds, plunger molds, and needle hub & cap molds.

The syringes are typically made from medical-grade PP material, and SINO offer a wide range of syringe mold configurations, such as 32-cavity, 48-cavity, 64-cavity, 96 cavity, and 128-cavity, to match different production capacity requirements.

SINO Mould is among the very few companies over the world with patented technology and deep expertise in medical syringe full hot runner systems.

Syringe Molds Technical Specifications

Syringe Composition:

(In some high-end medical applications, gaskets are not recommended to be produced by injection molding process)

Barrel: PP

Plunger: PP

Gasket: TPE or TPU

Needle hub: PP or PE

Needle Cap: PP

Syringe Volume Capacity:

1ml, 2ml, 3ml, 5ml, 10ml, 20ml, 50ml

Syringe Mold Cavity Number:

8 cavity-96 cavity

Syringe Mold Runner System Type:

Full hot runner (Recommended)

Semi-hot runner (Recommended)

Cold runner system (Not recommended )

Syringe Output Capacity Reference:

e.g., 48-cavity 2ml full-hot runner barrel mold: 17280pcs/h;

16-cavity 5ml cavity plunger semi-hot runner mold: 4800pcs/h

Syringe Molds Core/Cavity Steel:

Pre-hardened (wear and corrosion resistant)

Syringe Mold Accessories Standard:

DME/HASCO Standard

Syringe Mold Life:

Under normal conditions, the mold life is up to 5 million and with a one-year warranty.

Syringe Molds Special Hot Runner System-Sino Patent

For medical syringe molds, usually the waste can not be recycled, in order to reduce the waste of plastic costs, so clients could choose hot runner system, which can significantly improve production efficiency and reduce waste. And qualified hot runner system plays a decisive role in the stability of production and product quality.

SINO Mould has been deeply engaged in the design and manufacture of medical syringe molds for more than 20 years, and focuses on the research and development of special hot runner systems for syringe medical items to meet the high requirements of medical products in terms of precision and perfect appearance.

Through the mold flow analysis and continuous optimization of the mold structure, SINO Syringe Mould adopts the full side inject structure, which ensures that the amount of material feed into each cavity is the same, effectively avoiding the problems of flying edges, short shots, etc., and avoiding the harm to the human body. In addition, combined with the special heat nozzles for thin-walled products and the precise temperature control system, the filling is completed quickly at a high flow rate, and the surface of the product is smooth and transparent, with no flow marks and other defects.

Syringe Mold Images

We have delivered more than 300 sets of syringe molds for customers in more than 30 countries around the world, covering sizes from 1ml to 50ml, with mold cavities ranging from 16 cavities to 96 cavities, which are widely used in high-cleanliness syringe production lines.

Syringe Mould Project FAQs

How do you guarantee the quality of the mold?

We have more than 20 years of experience in designing and manufacturing medical syringe injection molds. We have strict process control from product structure, mold design, steel selection and tooling technology as well as quality inspection, which guarantees the reasonableness of the molds and the processing of high precision requirements. In addition, combined with our specialized hot runner system, which is applied to the production of medical syringe multi-cavity molds, the production of products is stable and the product quality is high. Before delivery, we will provide qualified inspection reports as well as samples to customers for confirmation, and all tests will be completed independently in the company to guarantee high efficiency and service.

What kind of after-sales services do you offer?

We provide global after-sales service support and can offer on-site engineering services within 24 hours in 25 countries. Before we deliver the production line, we provide detailed operational instructions and send engineers for factory debugging and training services. For ongoing usage, most accessories can be shipped within 24 hours.

How long is the mold delivery time?

Mold delivery time is 45-60 days after design confirmation, depending on the number of cavities, runners and steel selection. For special timing requirements, we support expedited arrangement.

Can you provide the whole syringe production line?

Yes, we provide one-stop delivery, including molds, injection molding machines, printing, assembly, packaging, sterilization and other equipment, as well as clean room manufacturing solutions, we customize a full set of solutions for you based on your project requirements.

I want to start to produce syringes, could you give me a detailed quote?

Of course. Please provide the size of syringes you need to produce (e.g. 1ml, 3ml, 5ml), and the expected daily output (20h per day), whether you need a complete line solution, our team will provide you with a customized solution according to your factory conditions and capacity targets.

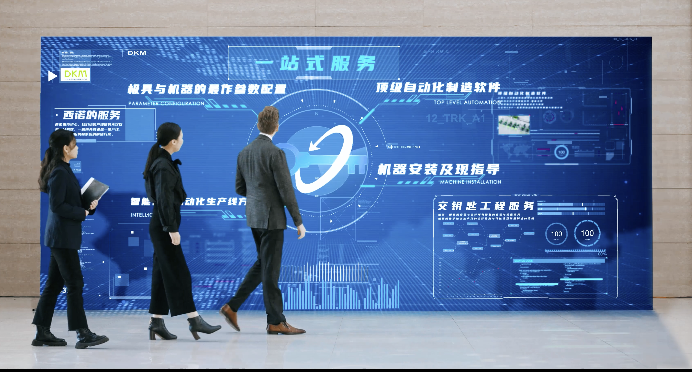

DKM Team Service

Turnkey Solution for Syringe Production Line

one-stop service

Overseas Engineers On-Site Service

Assistance in equipment installation and on-site training for workers

23 Service Spots Worldwide

covering Europe, Africa, Middle East and South America, supporting on-site maintenance

24 Hours Online Service from Headquarter

remotely provide technical support for injection molding technology and maintenance guide

Adequate stock of spare parts guarantee

adequate spare parts and support air freight