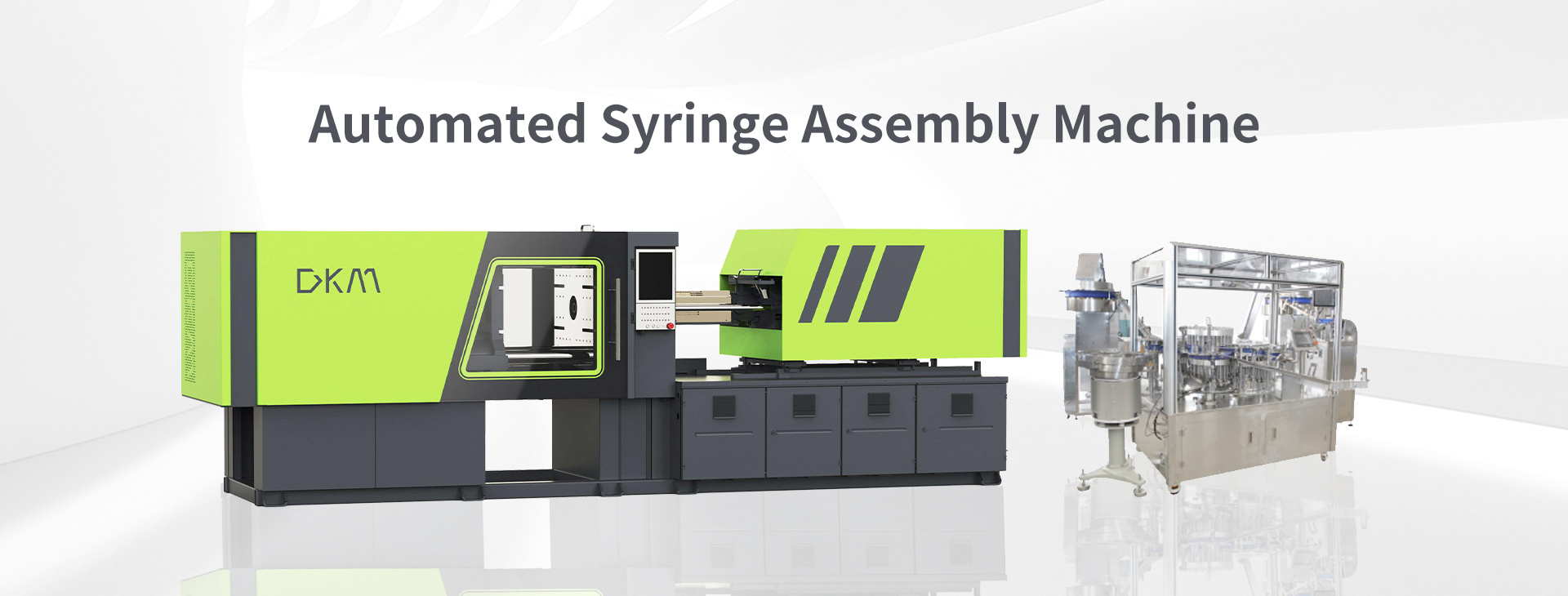

Syringe Assembly Machines

The syringe assembly machine automates the assembly of syringes, plungers, gaskets, and needle components. Optional inspection and decoration systems are available to ensure product quality throughout the production process. It is suitable for high-speed, large-volume manufacturing.

Capacity and Technical Table

| Production Spec. | Rate | Power source & Power | Compression air discharge |

|---|---|---|---|

| 2-3ml | 400pcs/min | ||

| 5ml | 400pcs/min | ||

| 10ml | 350pcs/min | ||

| 1ml | 350pcs/min | AC220V/2.5KW | 0.3m3/min |

| 20ml | 280pcs/min | ||

| 30ml | 220pcs/min | ||

| 50-60ml | 150pcs/min |

Advantages of DKM Assembly Machines

High Speed and High Capacity

Multi-station coordination with customizable capacity, capacity up to 20,000pcs/h.

Low Noise

Stable and quiet machine operation, suitable for medical production workshop.

Intelligent Operation Interfac

Optional high-performance touchscreen operation interface, easy to operate.

Clean and Dustproof Design

Better avoid debris or dust, ensuring a high-quality product.

CCD Visual Inspection is Available

Real-time monitoring of the assembly process, to avoid abnormalities and reject defective products.

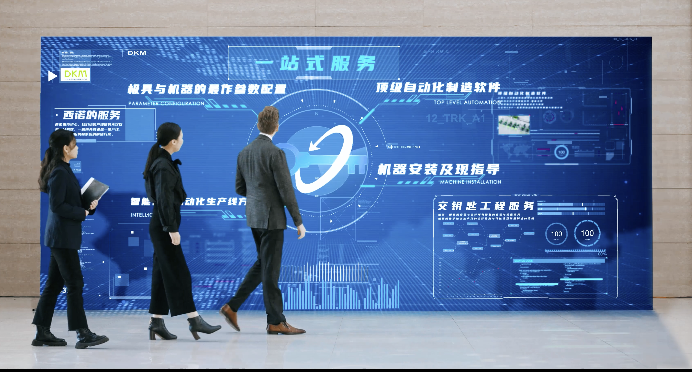

DKM Team Service

Turnkey Solution for Syringe Production Line

one-stop service

Overseas Engineers On-Site Service

Assistance in equipment installation and on-site training for workers

23 Service Spots Worldwide

covering Europe, Africa, Middle East and South America, supporting on-site maintenance

24 Hours Online Service from Headquarter

remotely provide technical support for injection molding technology and maintenance guide

Adequate stock of spare parts guarantee

adequate spare parts and support air freight