Plastic Pallet Hot Plate Welding Machine

Custom Hot Melt Welding Model

Our state-of-the-art Plastic Pallet Welding Machine delivers unparalleled efficiency and precision for industrial welding applications. Engineered for high-volume production, this advanced system boasts:

- 300 pallets/hour production capacity

- 99.9% weld success rate

- Dual temperature control with PLC/HMI touchscreen interface

- Material compatibility: PP, PE, and HDPE

- 2-year comprehensive warranty

Key Features & Benefits:

- Precision Engineering: Adjustable for pallet sizes 800mm-1500mm.

- Heavy-Duty Performance: 2T+ load capacity with stainless steel construction.

- Smart Automation: High-performance cylinders and precision alignment systems.

- Energy Efficient: 30% energy savings with smart thermal control.

- Cost Effective: Reduces labor costs by 60%.

- Quality Assurance & Support: CE-certified for industrial safety standards.

- Durable surface treatments: Electrostatic spraying + hard chrome plating.

- Global support: Free design consultation + technical assistance.

- Fast worldwide shipping: This eco-friendly welding solution combines reliability, customization, and cutting-edge technology - making it the ideal choice for modern manufacturing operations requiring high-throughput plastic pallet production.

Features of Plastic Pallet Hot Plate Welding Machine

1. Precision Thermal Control: Temperature-regulated metal plate (200–300°C) | Material-specific heat profiles (optimized for HDPE/PP) | Automated temperature monitoring.

2. High-Strength Bonding: Molecular diffusion creates parent-material strength | 0.5–2 MPa pressure ensures void-free joints | Leak-proof seals for liquid/gas containment.

3. Automated Process Consistency: PLC-controlled heating/pressure/timing cycles | Synchronized fixture movement (±0.1mm precision) | Repeatable results for high-volume production.

4. Material Compatibility: Engineered for thermoplastics (HDPE/PP preferred) | Maintains 100% material structural integrity post-weld | No adhesives or consumables required.

5. Quality Assurance: Tensile testing validates joint strength | Visual inspection for surface uniformity | CE-certified process controls.

6. Production Efficiency: Cycle times under 2 minutes (typical) | Simultaneous multi-joint welding capability | 24/7 operation with stainless steel components.

7. Energy-Smart Design: Thermal insulation minimizes heat loss | Recuperative heating options available | 30% lower energy vs. ultrasonic welding.

Application Example

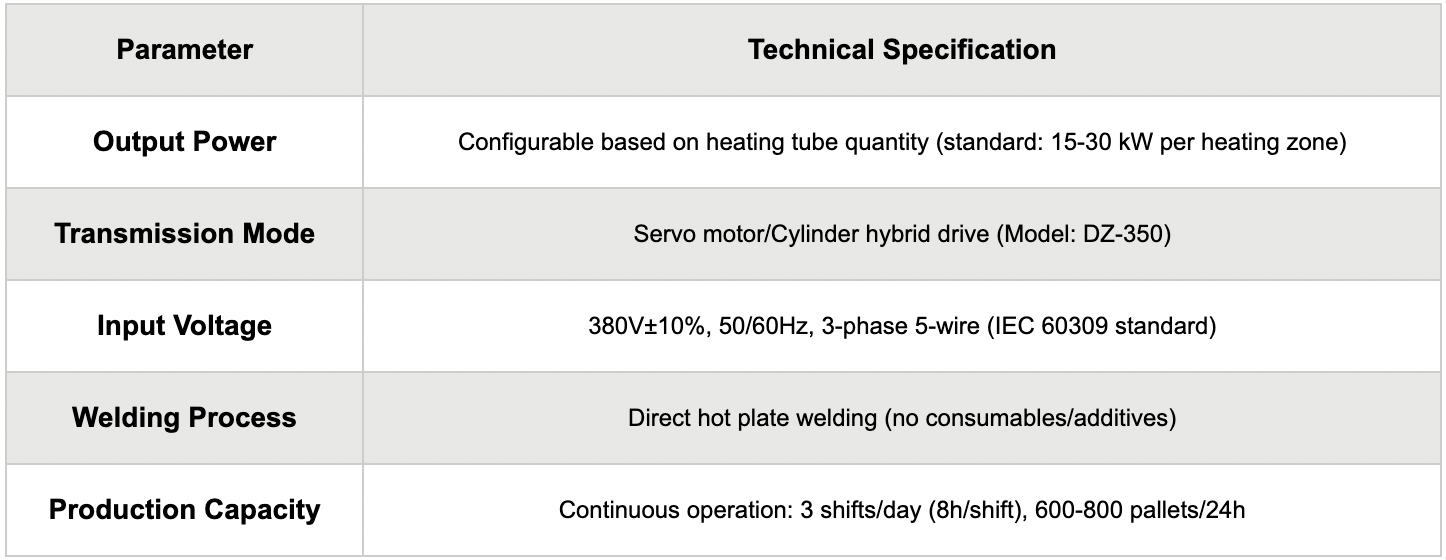

Plastic Pallet Welder Parameters

Advantages of Dizo Custom Plastic Pallet Hot Plate Welder

Works with Any Size

Hot plate welding accommodates plastic pallet parts of all sizes without area limitations.

Any Surface Compatibility

Plastic pallet hot plate welders can bond any surface type with ease.

Strong and Adaptable

The process adapts to diverse shapes while maintaining robust joint strength.

Customized for Each Material

Optimized for different materials, ensuring precision and user-friendly control.

Hot Plate Welding Solutions in the Plastic Welding Industry

Hot plate welders have established themselves as the industry-standard solution for creating strong, reliable plastic welds across diverse industrial applications. These precision machines excel at handling complex welding tasks for automotive components, electronics enclosures, and consumer goods manufacturing. Our advanced hot plate welding solutions deliver consistent, high-quality results with a wide range of thermoplastics including PP, PE, ASA, ABS, PC, PET, PMMA, PVDF, and PVC. Featuring innovative technologies like automatic mold cleaning and precision depth control, our systems maintain exceptional performance standards whether welding flat or curved surfaces. The combination of versatility, repeatable 99.9% weld success rates, and energy-efficient operation makes our hot plate welders the preferred choice for demanding production environments requiring durable, leak-proof joints.

Other Hot Plate Welding Applications

Hot plate welding delivers optimal performance with thermoplastics such as PP, PE, ASA, ABS, PC, PET, PMMA, PVDF, and PVC, particularly for large, complex components. This process creates structurally sound joints with superior sealing properties, excellent thick-wall compatibility, and clean weld lines without material degradation. The technology serves critical functions across multiple industries: in automotive manufacturing for waterproofing irregular components, in appliance production for durable housing assemblies, in industrial storage container fabrication, and in medical device manufacturing where precision and hermetic seals are paramount.

Hot Plate Welder for Automotive InteriorComponents

Hot plate plastic welding machines play a vital role in automotivemanufacturing by enabling precise joining of interior components. Thesemachines effectively weld critical parts such as door panels, soundinsulation boards, trim panels, dashboards, instrument panels, and gloveboxes –all while ensuring structural integrity and compliance with stringentindustry standards.

Hot Plate Welder for Automotive ExteriorComponents

Our hot plate plastic welding process effectively joins critical safetycomponents such as tailights, turn signals, and brake lights, whileseamlessly integrating aerodynamic features (e.g., spoilers) and protectiveelements (e.g., mud flaps, rear panels). This technology guarantees bothstructural integrity and premium aesthetic quality, fully complying withindustry standards.

Hot Plate Welder for Automotive FunctionaParts

Our hot plate plastic welding technology is specifically designed for criticalvehicle components, including fuel tanks, battery casings, expansion tanksradiators, brake fluid reservoirs, filters (fuel, oil, and air), intake manifoldsand air intake pipes. Each welded component meets stringent requirementsfor structural integrity and long-term reliability.

Hot Plate Welder for Household Appliances

Hot plate plastic welding technology is widely employed in appliancemanufacturing for creating durable connections in storage containers (forwashing machines and refrigerators), control panels, multi-layeroven/microwave doors, and button/bracket installation. This advancedwelding method guarantees robust structural integrity, reliable sealingperformance, and superior aesthetic finish – meeting the highest qualitystandards in the appliance industry.