PETRI DISH MOLDING LINE

Precision Engineering: Elevate Your Medical Petri Dish Production Line Manufacturing

Petri Dish Injection Molding Line

DKM is a leading provider of high-performance medical disposable Petri dish molding and production line solutions. We are committed to helping medical Petri dish companies enhance their production capacity and product quality. By optimizing the manufacturing process, DKM ensures fast delivery times and comprehensive services to save time and reduce costs for our clients.

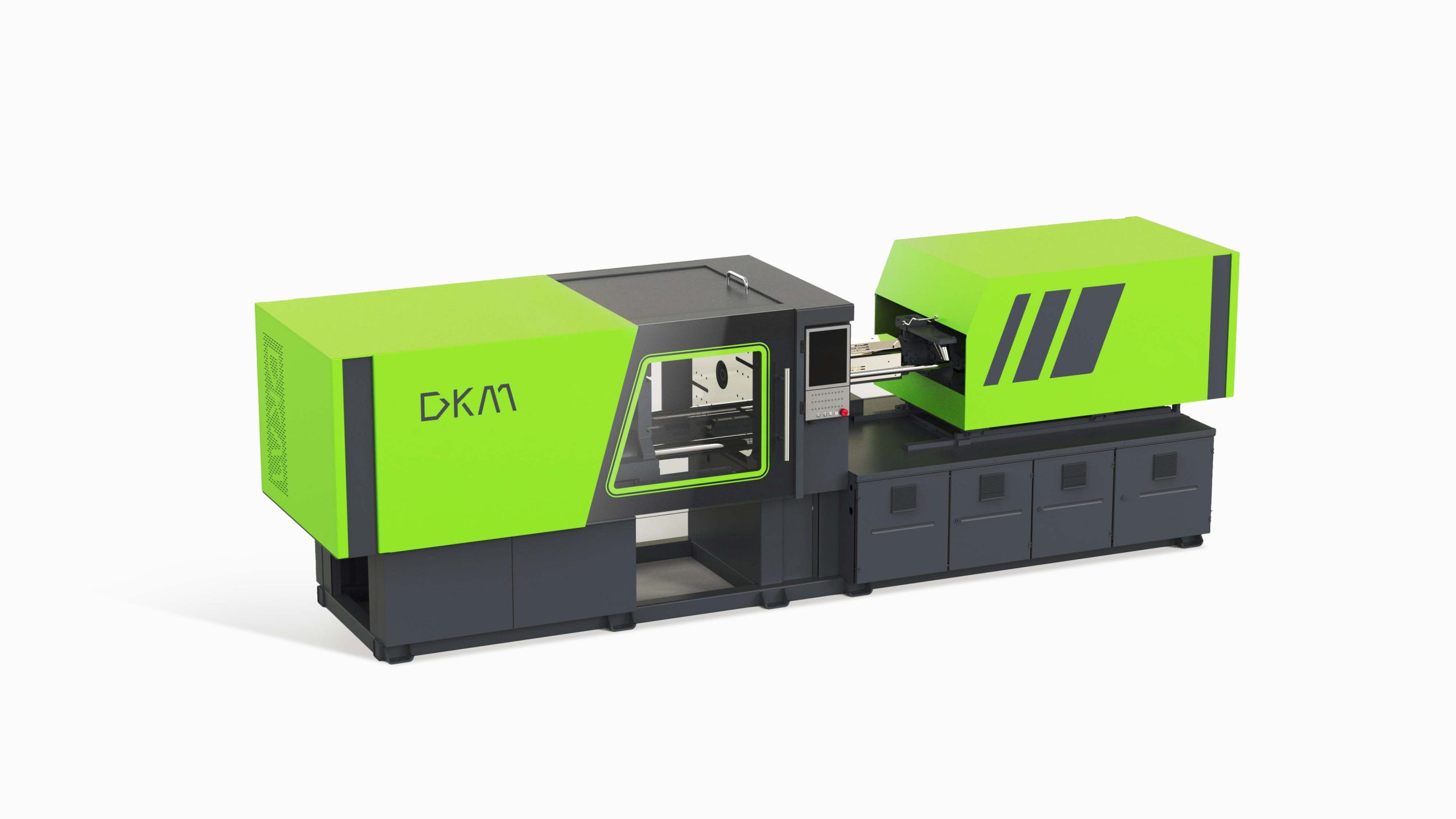

- Petri Dish Injection Molding Machine

- High energy efficiency: The full-electric injection molding machine is directly driven by the servo motor, and the energy conversion efficiency can reach more than 95%, which is much higher than the 30-50% of the traditional hydraulic system.

- High positioning accuracy: The servo motor and precision control system of the full-electric injection molding machine can achieve positioning accuracy of 0.01mm to ensure the accuracy and consistency of the injection molding products.

- Fast response: The servo motor has a fast response time of 10 ms, which is significantly quicker than the hydraulic system's response time of 100 ms.

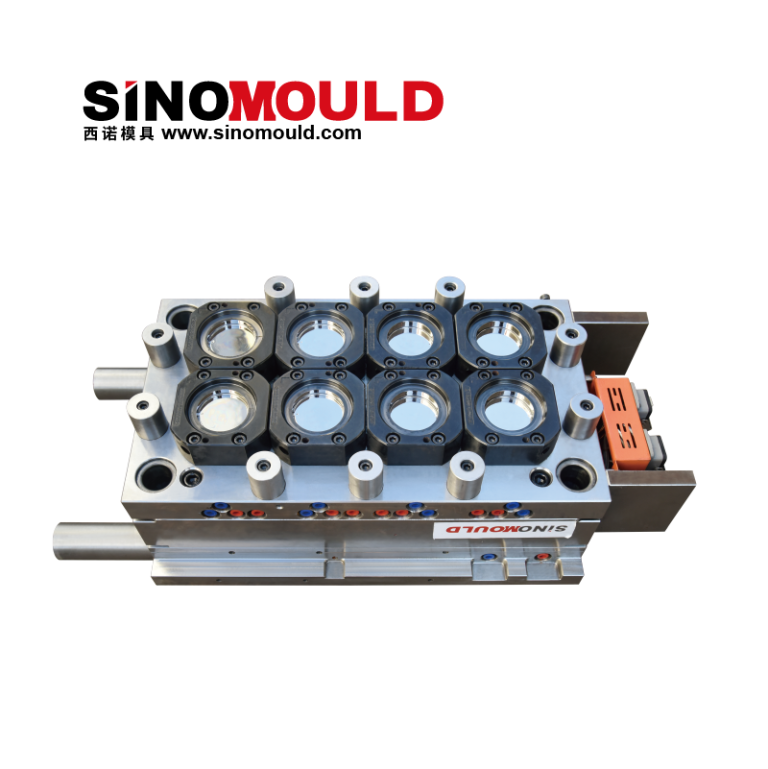

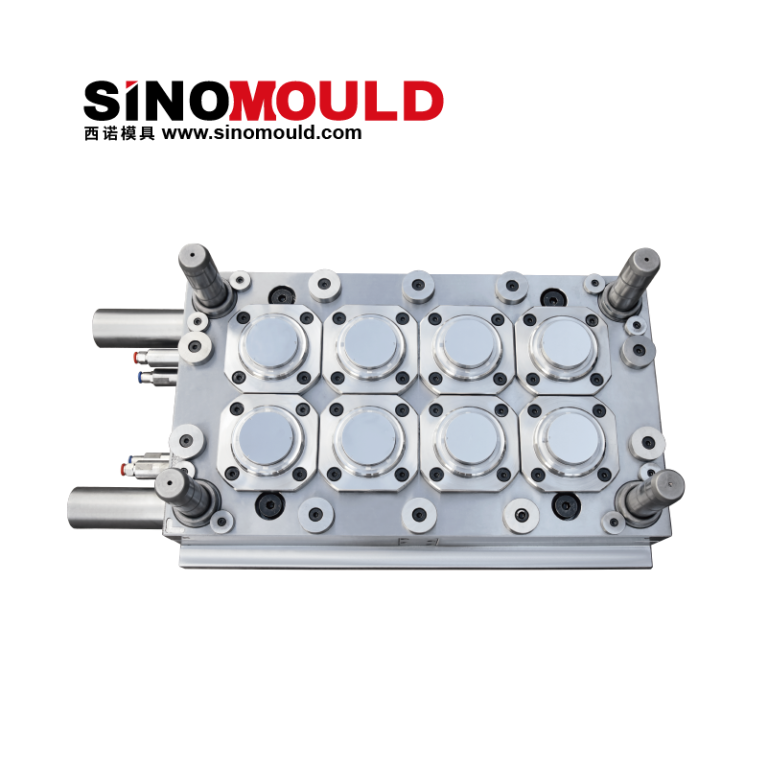

- Petri Dish Mould

- Professional Mould Design: DKM's Petri dish molds are designed with patented hot runner edge gates, ensuring precise and efficient injection molding. The special steel material selection and correct steel treatment process guarantee durability and longevity.

- Interchangeable Standard Parts: Our molds feature interchangeable standard parts, making maintenance and replacement easy and cost-effective.

- Accurate Machining: Each mold undergoes rigorous dimensional control and precise machining processes to ensure high-quality and consistent production.

- DKM Petri Dish Lines Solution

- High-Speed Injection Molding: Our state-of-the-art injection molding machines and superior Petri dish molds ensure efficient and high-quality production.

- Customized Project Planning: We optimize project plans based on the specific Petri dish specifications and production capacity required by our customers.

- Complete Production Equipment: DKM provides all the necessary equipment for Petri dish production, including molders, assembly machines, packaging machines, and sterilization equipment.