PET Bottle Preform Mould

With two decades of dedicated expertise and innovation in PET bottle preform mould technology, SINO has grown into a globally renowned leading manufacturer of PET bottle preform moulds. The company produces over 500 sets of preform molds annually, with cavity configurations ranging from 48 to 168 cavities, catering to diverse production needs. Through 25 years of continuous technological refinement and heritage, SINO’s PET bottle preform moulds deliver enhanced durability, easier maintenance, and higher production efficiency, consistently providing customers with stable and high-performance solutions.

SINO PET Bottle Preform Mould Advantages

- Exceptional Durability Bottle Preform Mould

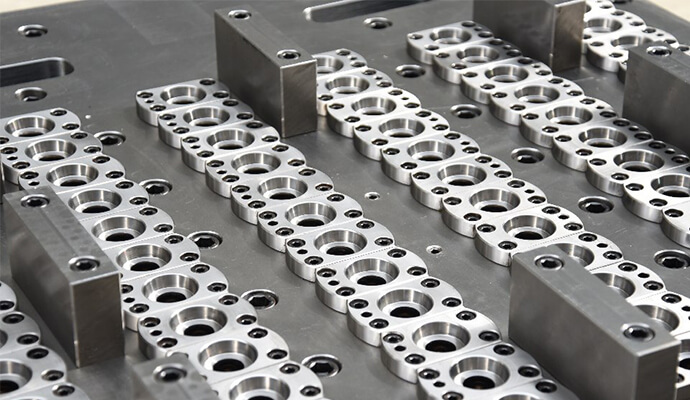

Manufactured with high-quality European stainless steel and advanced processing techniques, coupled with precise heat treatment, the mold’s strength and wear resistance are significantly enhanced. It supports flexible configurations from 8 to 168 cavities, which are fully interchangeable. The neck inserts can be replaced quickly, greatly reducing downtime. An efficient external mold cooling device is also available to further enhance continuous production stability and mold service life.

- High-Speed Molding Cycle

Utilizing a professional PET valve-gate hot runner system, optimized runner design, and advanced cooling technology, the injection cycle is significantly shortened while improving surface quality and consistency of the products. For example, a 72-cavity mold for 26-gram preforms achieves a cycle time of only 12 seconds, making it ideal for high-volume, high-speed production environments.

- Rapid Delivery Capability

With agile manufacturing and modular design capabilities, standard neck preform molds ranging from 48 to 96 cavities can be produced and delivered within two weeks, effectively reducing customer wait time and accelerating time-to-market.

- Ultra-High Machining Precision

Equipped with high-precision CNC lathes, grinding machines, and dedicated mold processing equipment, key dimensional tolerances are controlled within ±0.005 mm. In 2024, SINO MOULD will fully achieve intelligent and automated production of PET preform molds, further enhancing precision stability and manufacturing efficiency.

PET Preform Mould

- Cavity:8,16,32,48,64,96,144,168

- Common Capacity:0.2L, 0.5L, 1L 2L 5L, 10L, 20L

- Mold Runner System Type:Anole Hot Runner

- Core/Cavity Steel:S136/DIN1.2083 made in Swiss/German, tempered with HRC 50±2

- Mold Accessories Standard:Measure up to Husky standard or <SINO PET Preform Mould Standard>

Mold Life:Under normal conditions, the mold life is up to 5 million and with a one-year warranty.

Preform Mould Testing Video

Preform Mould Image

DKM Team Service

Design Collaboration

From concept to DFM report, we work with your team.

Spare Parts Program

Ensure maximum uptime with our guaranteed parts inventory.

Global Support

24/7 technical support and fast turnaround on maintenance.

Ready to Optimize Your Molding Performance? Send us your preform design for a free quotation