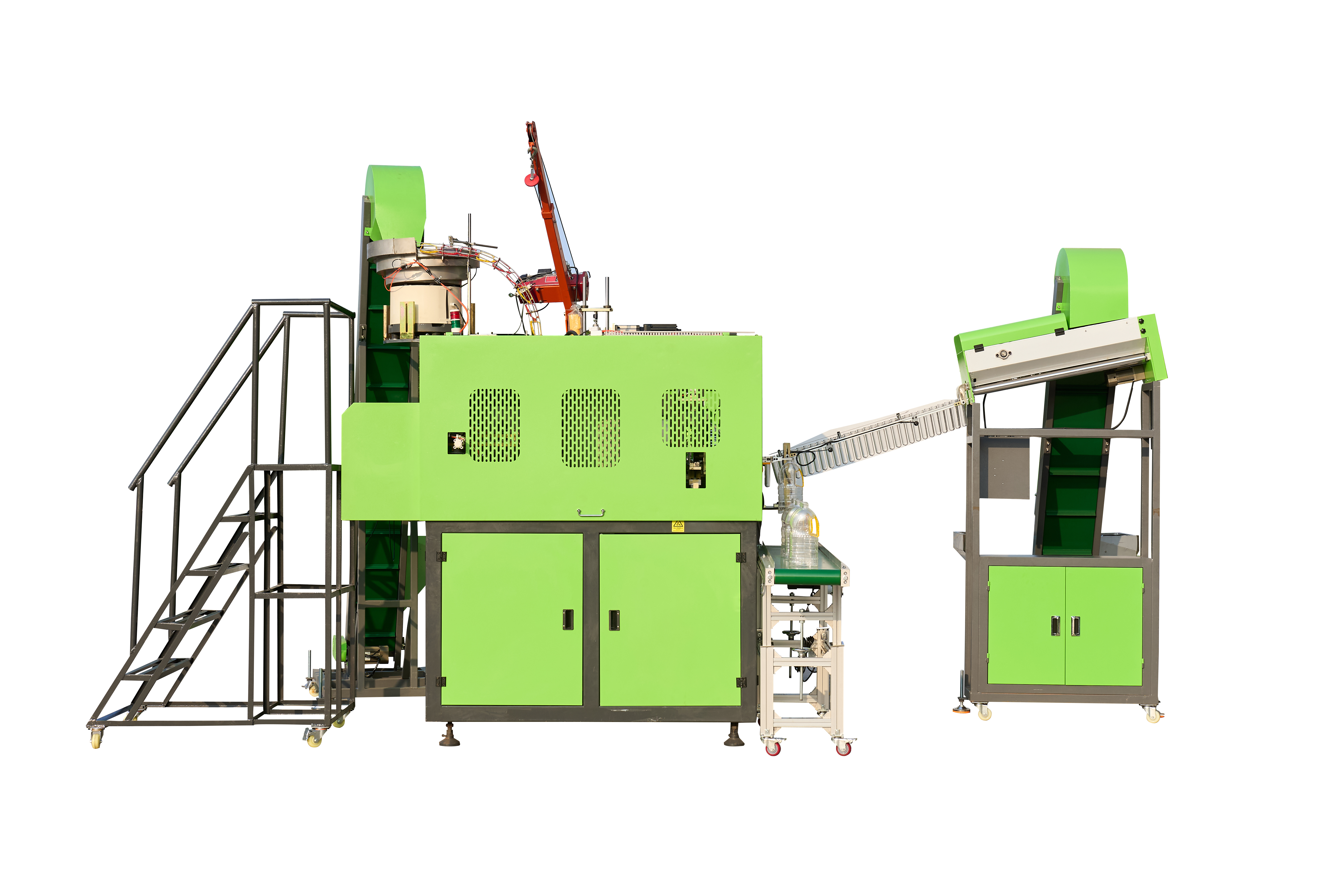

PET Bottle Preform Molding Production Line

DKM specialized on providing multi-cavities PET Bottle Preform Molding Production Line service. It had been devoted on research and development on high efficiency PET bottle preform molding line turnkey solution. Till now, PET preform machine had already developped to third generation which special for high speed running and more then 1000 sets of PET bottle preform injection molding lines had already successfully delivered and got many good feedback from the users.

- 48/72/144 Cavities 12g 28mm Standard Preform Molding Line

- Cycle Time :10-12.8 seconds

- 48/72 cavities preform mold delivery ≤ 2 weeks

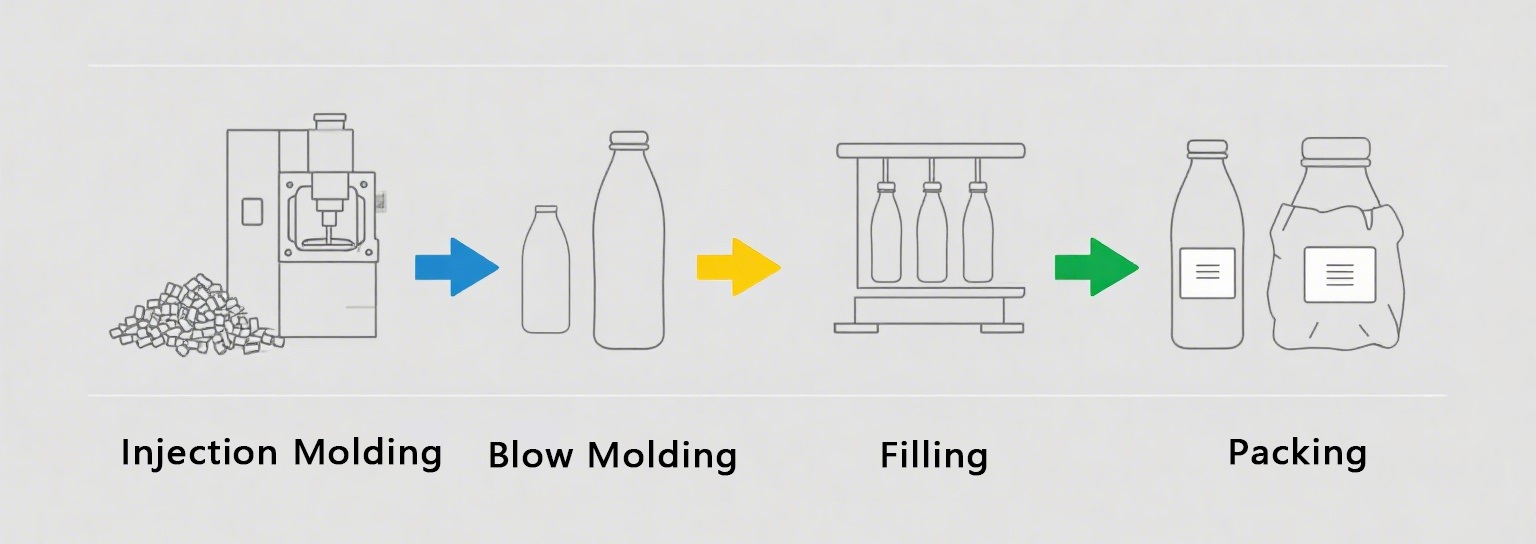

PET Preform Production Process

- STEP 1 Injection Molding

Raw material drying

Melting & injection

Cooling & shaping

Ejection & inspection

- STEP 2 Blow Molding

Preform heating

Stretch blow molding

Rapid cooling

- STEP 3 Filling

Preform sterilization

Liquid filling

Nitrogen pressurization

- STEP 4 Packaging

Labeling & ink-jet coding

Handle mounting

Neck cutting

Shrink bundling

Palletizing & warehousing

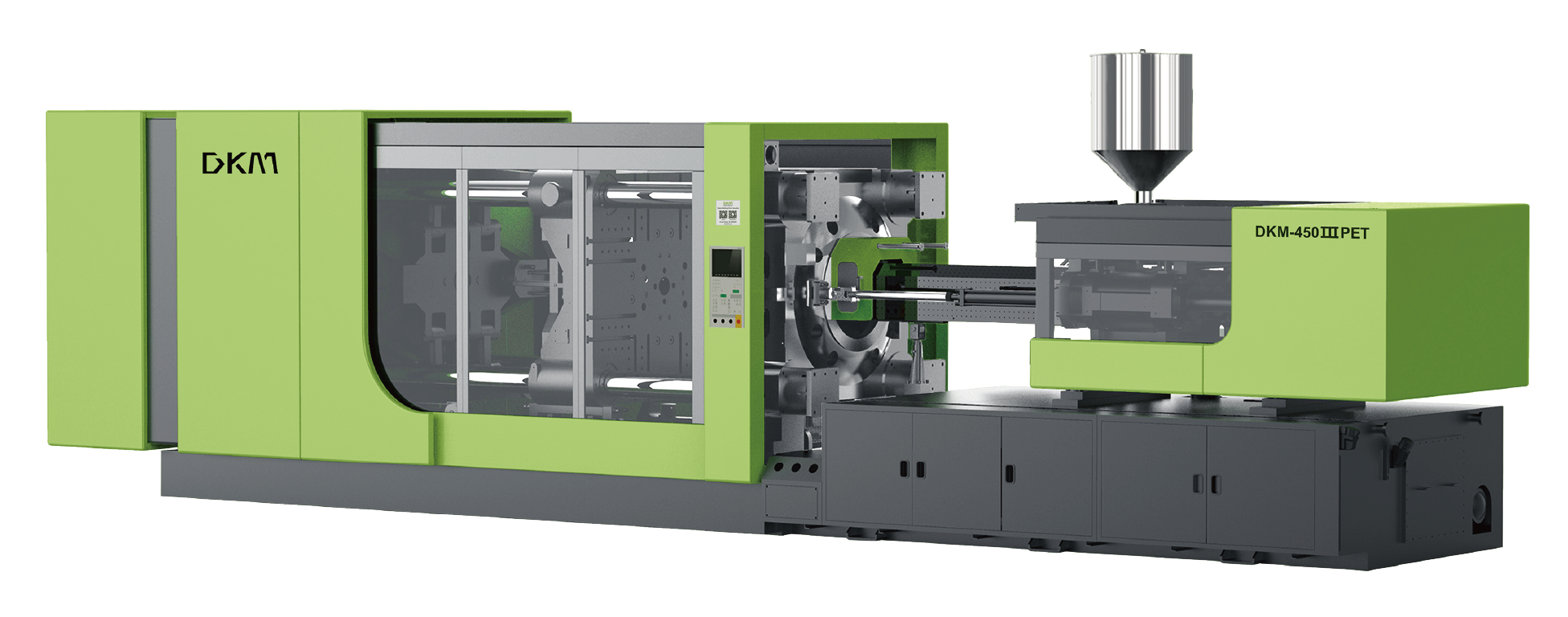

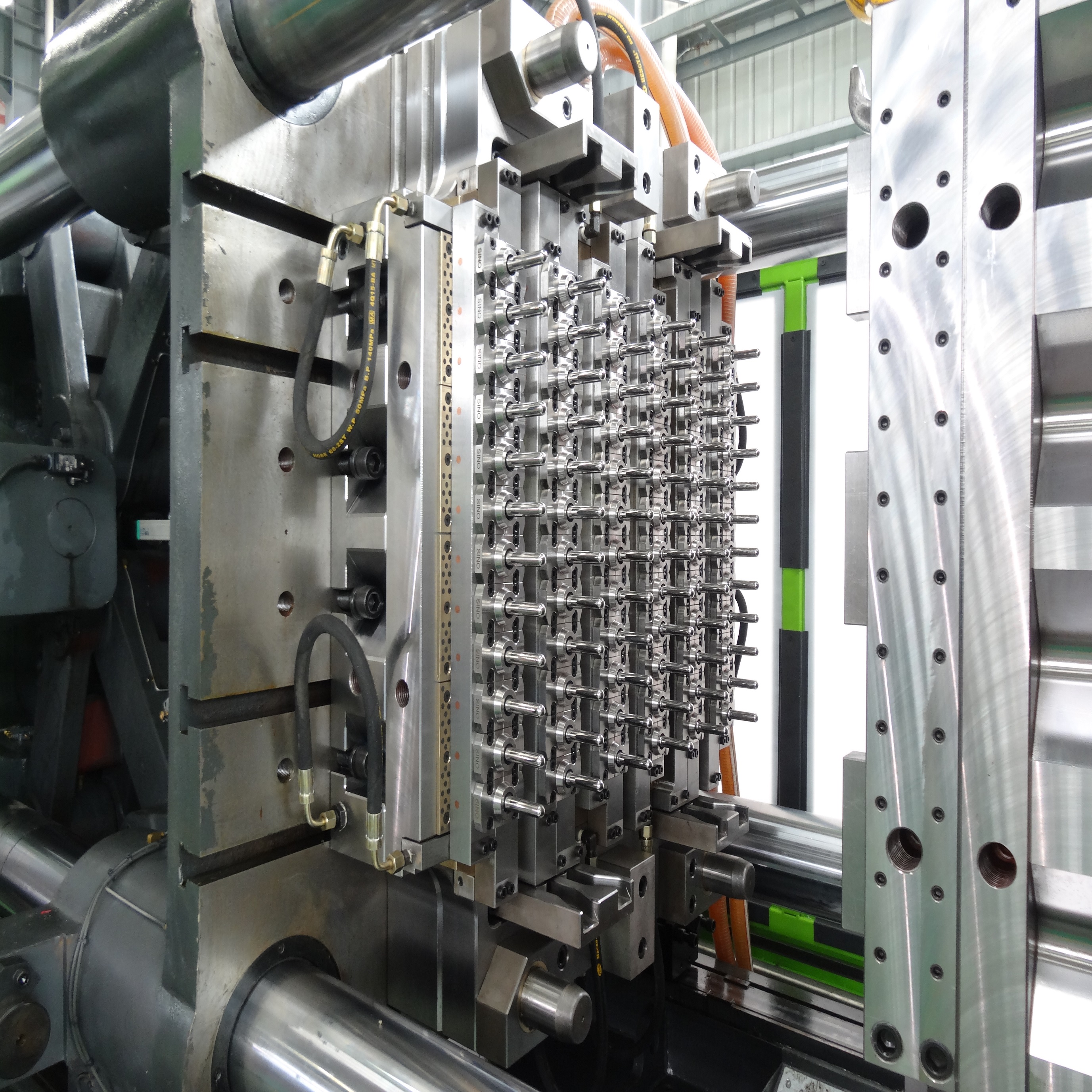

PET Bottle Preform Injection Molding Machine

- Bigger L/D rate and high plasticization with professional screw; Available in a range of 350-650 Ton.

- Double Barrel for high speed injection molding is Optional.

- Special Machines base design fit for speical dimension of PET preform mould.

- Machine designed for high Speed, high repeatability, high reliability, high efficiency.

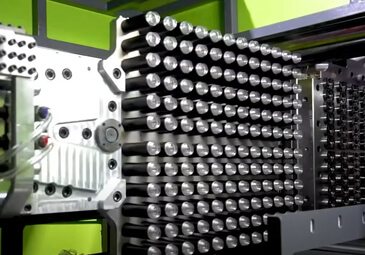

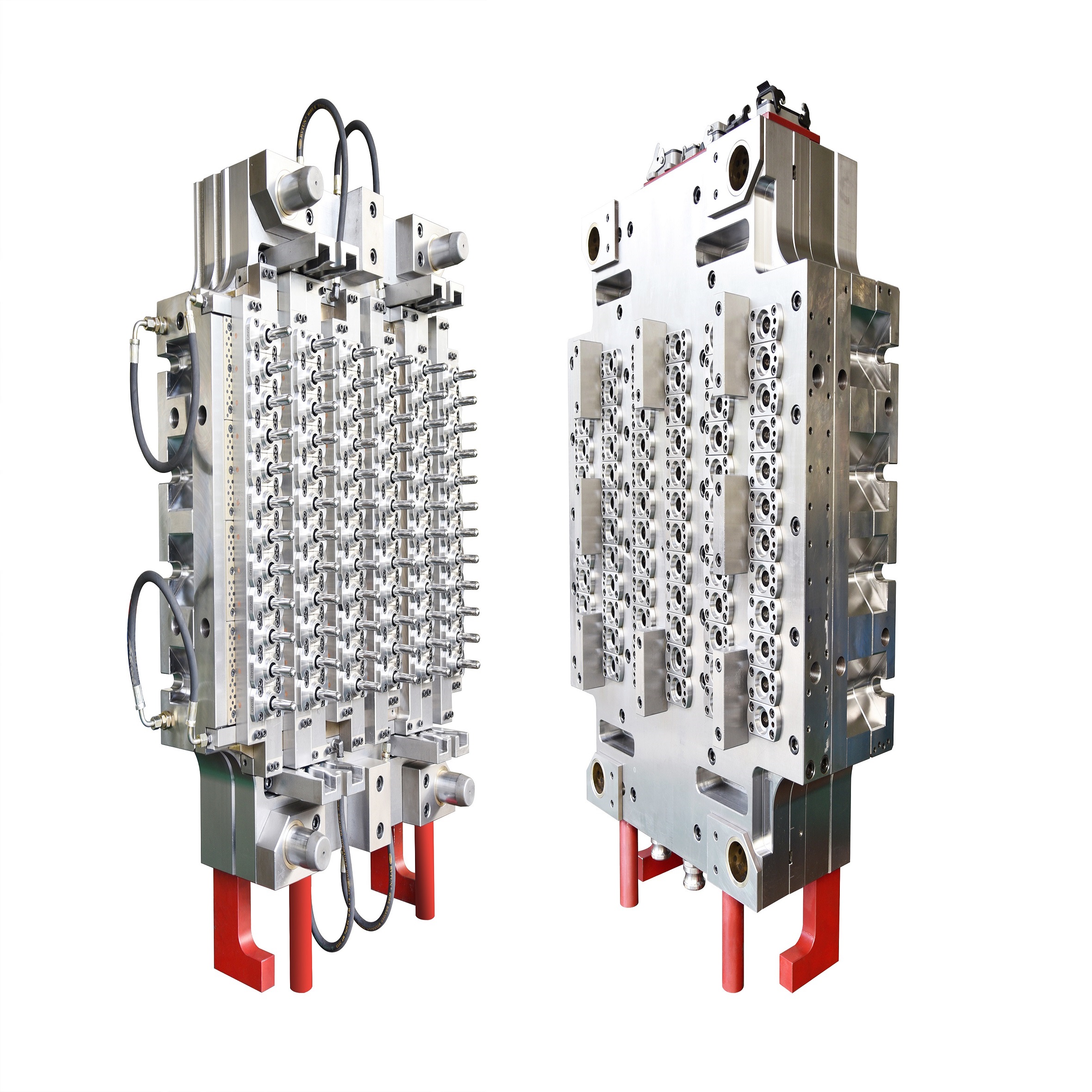

PET Bottle Preform Molds

- 8-144 cavities with interchangeable characteristic & quickly neck insert change, outside mold cooling unit is optional.

- High standard EURO stainless steel material and process with suitable heat-treatment..

- Professional PET valve gate hot runner system, with 23 years experience.

- High speed with molding cycle 12 seconds for 26g preform molds.

- Standard neck preform mould 48 cavities to 96 cavities can be delivered within 2 weeks.

- High precision lathe, grinding technology and other preicsion tooling, Critical dimension with 0.005mm tolerance. (in 2024, SINO MOULD PET preform molds tooling and machining will realize completely Intelligence and automation)

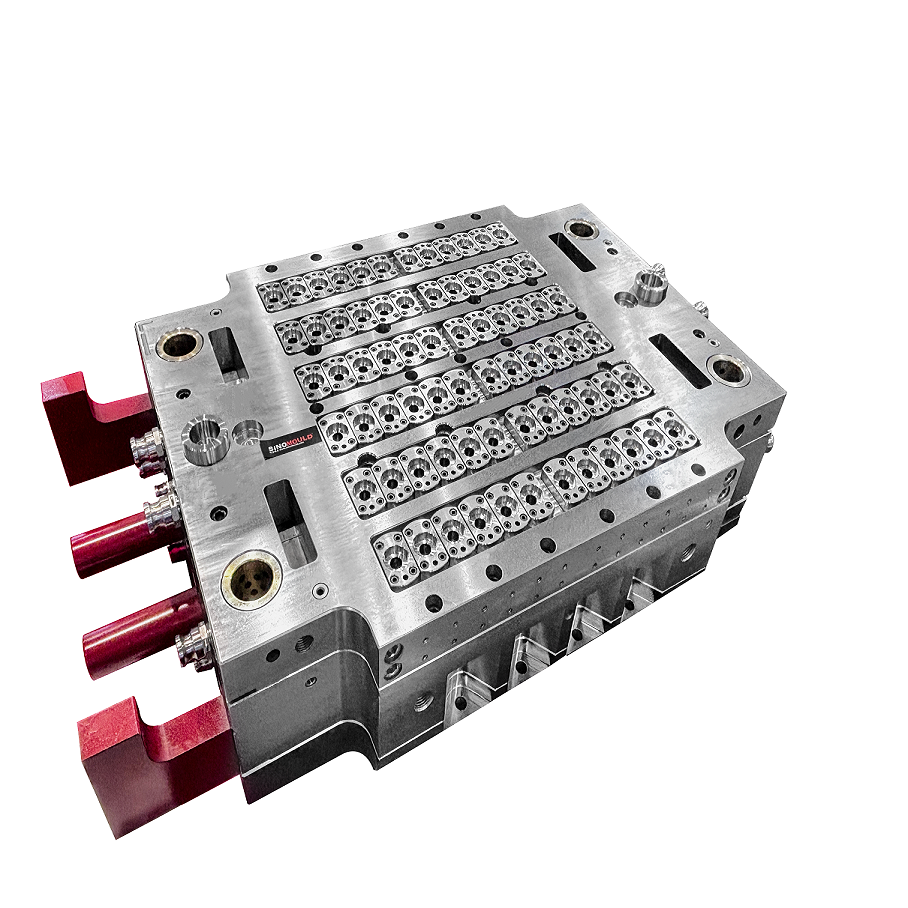

72-cavity PET Preform Mould

Product: 72-cavity PET preform mould (16g)

Mould material: S136

Mould size: 1200*900*573mm

Cycle time: 11s

Description: Bottle preform mould is provided by Sino Mould,with selected S136 steel,which assures long life running; We use Anole hot runner and 72 tips valve gate system; The production cycle time is only 18s, the average daily output is up to 345600pcs.

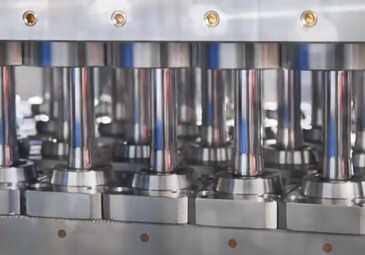

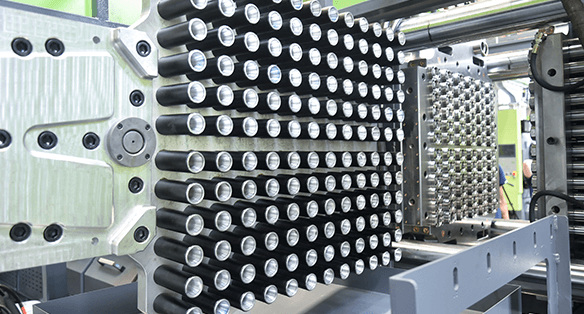

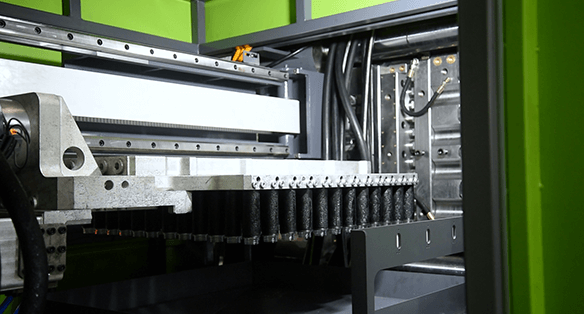

Side Enterance Servo Robot

- Side Enterance Servo Robot with gripper plate-preform Injection Molding Out Mould Cooling Robot.

- 1 station to 3 stations cooling jigs are optional.

- Universal cooling jigs for different preform height.

- Casting iron base for robot base and main frame.

- Jigs and Gripper Plate use aviation hard aluminum PLC controller.

Professional and efficient auxiliary machinery

PET bottle preform molding dedicated dryer, loader and chiller.

Save Time and Manpower As the hopper body and bottom are designed separately, therefore it is convenient to clean materials and quite simple and quick to renew materials as well. A,L feet frames, reciever of hot air, the filter of inlet of fan, the filter of air exhauster, magnetic base, magnetic iron of bunker are available for selection.

XD dehumidifying,drying and feeding unit equipped honeycomb dehumidifier. The moistureproof drying material tube adopt bottom blowing design with circling air exhausting device,prevent heat energy emitting keep temperature, improve drying effiency.The dew-point monitor indicator for customer selection, which can monitor the dew-point.

Mircocomputer control system, control machine running automatically(with timing switch and full-functional alarming system)

The main engine and the material hopper are designed separately, and thus it is safe, easy and convenient to be operated .The whole operation is controlled by MicroTrip computer.Equipped with an independent filter, which is very convenient to clean up dust.

XMD mold dehumidifier is mainly used in the plastic and rubber molding. As the mold use the cooling water to reduce the moulding cycle, which result in the problem of water condensation, it is the most applicable for PET and XMD bottle shooting out particularly.

The conveyor belt ensures fast, stable and efficient transfer of preforms on the production line, reducing manual handling and waiting time and making it more intelligent and automated.

• Complete model spectrum: from 2-cavity to 6-cavity, 0.1 L–20 L, 1,000–4,500 bph.

• Servo + IR precision heating: 32-bit embedded processor with phase-triggered power control; lamp power is linearly adjustable; preforms rotate and revolve for even heating and high clarity.

• Energy-saving design: compact oven with continuous rotary heating saves 20–30 % power versus traditional models; three-stage air circuit (low-pressure motion/pre-blow, high-pressure blow) minimizes air consumption.

• High stability: double-crank toggle clamping, rigid linear guides, Delta control system; automatic fault alarm; mold change in 30 min.

• Two layouts: in-line or stand-alone, seamlessly connecting to the blow-molder discharge conveyor.

• Servo positioning + robot gripper, one-shot snap-in, yield ≥ 99.5 %.

• Handles fit bottle necks 30–120 mm; jig change in 10 min; single- or dual-head models 1,200–2,400 bph.

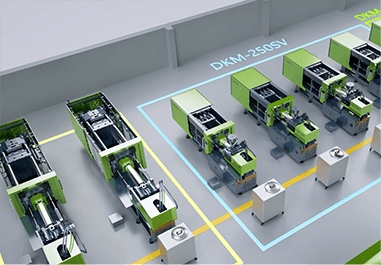

Preform Injection Molding Solution One-Stop Service

- High speed outside of mould cooling and collection robot, double barrel for high speed plasticization optional.

- Detail Factory Layout & Water/Air/Electrical Power Layout & Automation System Counselor.

- Engineer Sending & Machine Installing & Parameter Adjustment & Training Service, On Site & Online Training Course.

DKM Multi-cavities Preform Molding Production Line Video

Here are videos of some of our preform production lines