Preform Injection Molding Machine

DKM-PETIII injection molding machine is the result of DKM’s approximately 20 – year experience in the PET injection field.

The mechanical components of DKM-PETIII injection molding machine are all purchased from first – tier brands at home and abroad. It features a high melting rate, rapid mixing, high – speed injection, and high – precision injection.

It is an ideal choice for industries such as liquid packaging and household parts.

Why Choose DKM Preform Machine

- High Efficiency & Output:

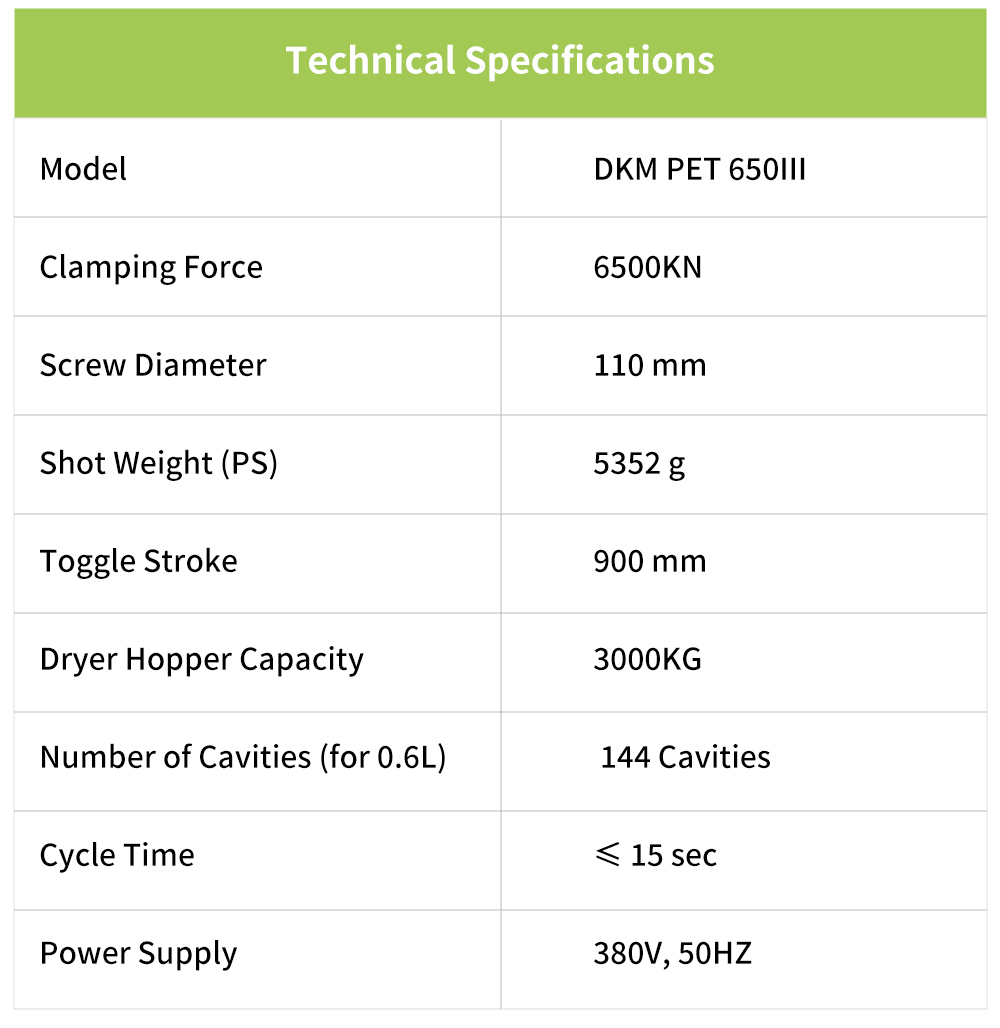

DKM-PETIII is equipped with a more powerful power system, with three systematic upgrades in maximum hydraulic pump pressure, motor power, and electric heating power, which greatly increase the machine’s injection speed, effectively shorten the product forming cycle, and signifi-cantly enhance product quality.

The screw and barrel assembly has added a holding pressure cylinder function, and is equipped with electric material storage to achieve synchronous gel melting, greatly shortening the forming.

- Energy Saving:

DKM-PETIII is equipped with a more powerful power system, with three systematic upgrades in maximum hydraulic pump pressure, motor power, and electric heating power, which greatly increase the machine’s injection speed, effectively shorten the product forming cycle, and signifi-cantly enhance product quality.Our all-new servo pump system reduces power consumption by up to 60% compared to traditional hydraulic machines, cutting your operational costs dramatically.

Superb Stability & Durability:

DKM-PETIII effectively enhances structural stability and rigidity by increasing wall panel thickness, significantly reducing overall product deformation during the injection molding process. This improvement boosts dimensional accuracy and shape consistency, substantially improving product quality to meet the stringent requirements of high-end liquid packaging.

Professional and Fast Engineering Support:

DKM team offers global on-site support and 24/7 online technical assistance. Backed by decades of experience in injection molding projects, our team provides comprehensive technical guidance — from injection molding machines to mold and injection molding parameters. DKM team ensures timely support, minimizes downtime, and guarantees efficient and stable production for customers.

Applications:Ideal for producing preforms for mineral water bottles, carbonated soft drink (CSD) bottles, edible oil bottles, juice bottles, and pharmaceutical bottles.

Why Choose DKM Preform Machine?

- 20+ Years of Manufacturing Experience

- CE & ISO 9001 Certified

- Full After-Sales Support: We provide installation guidance, operator training, and a comprehensive 1-year warranty with lifelong maintenance support.

- Customized Solutions: We can customize the machine configuration, including the hot runner brand and cavity number, to meet your specific production needs.

- Contact us today for a free quotation and detailed product brochure! Our sales team is ready to provide you with the best solution for your business.