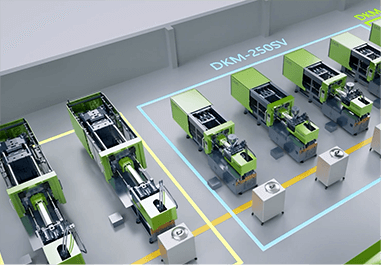

Paint Bucket Molding Line

DKM is professional in paint bucket mould and machine line, has provided more than 300 sets of 20L / 5 Gallons paint pail molding line.

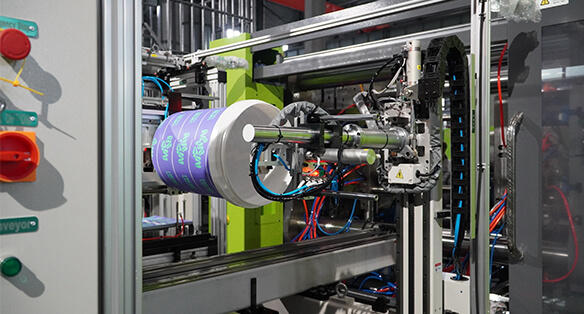

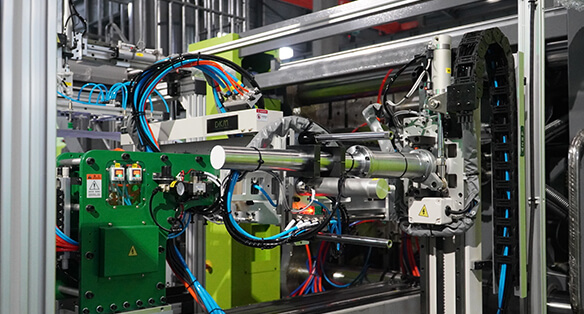

From 5L, 10L, 20L… square, round, oval and other paint buckets moulding machine, DKM was continuous innovation and improvement on machines line delivery time, cycle time, stability , our 20L in mold labeling paint bucket production, work with 600T, 650T and 700T high speed injection molding machine and side enter robot which were successfully achieved 14.8 second cycle time.

A big capacity paint pail production line contained dedicated high speed paint bucket molding machine, perfect paint bucket mould, side enter robot/IML robot, conveyor belt, and other auxiliary equipment, chiller, cold water tower, air compressor, loading machine, etc…

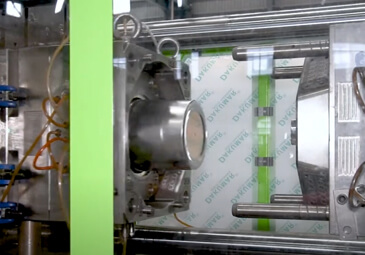

Plastic Paint Bucket Molding Machine

- 3-axis linkage to realize material charging mould opening and ejection at the same time.

- High speed injection, high precision single cylinder injection system and high response servo system.

- Using world famous brands optional parts in electric and hydraulic elements and latest version computer controlling system.

- Special designed for Low MFI plastic raw material, suitable for MFI 4-8.

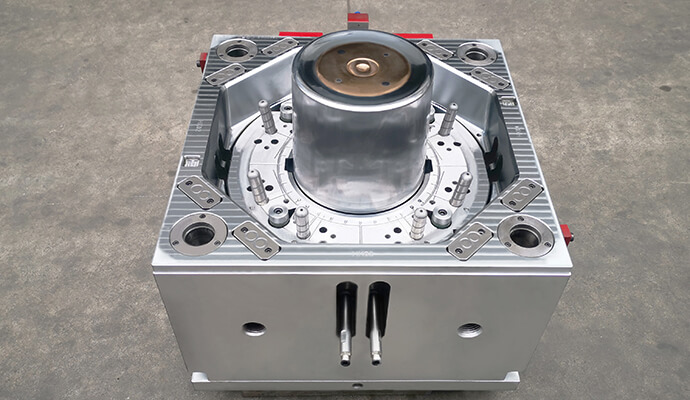

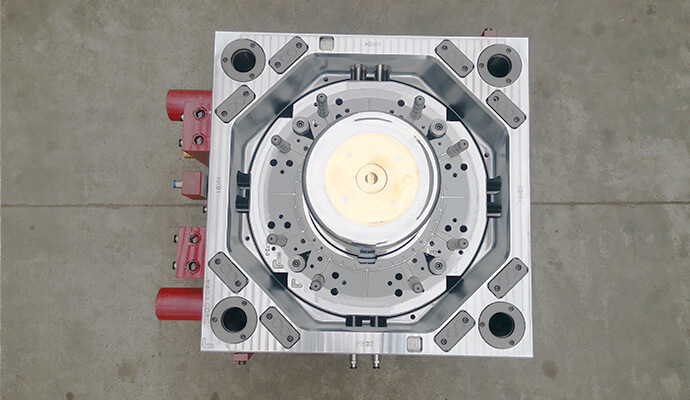

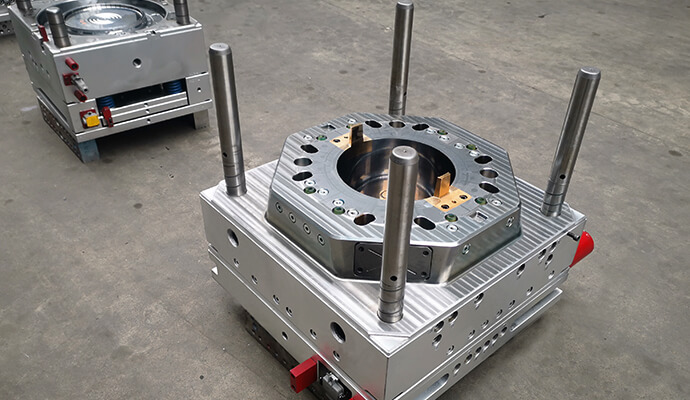

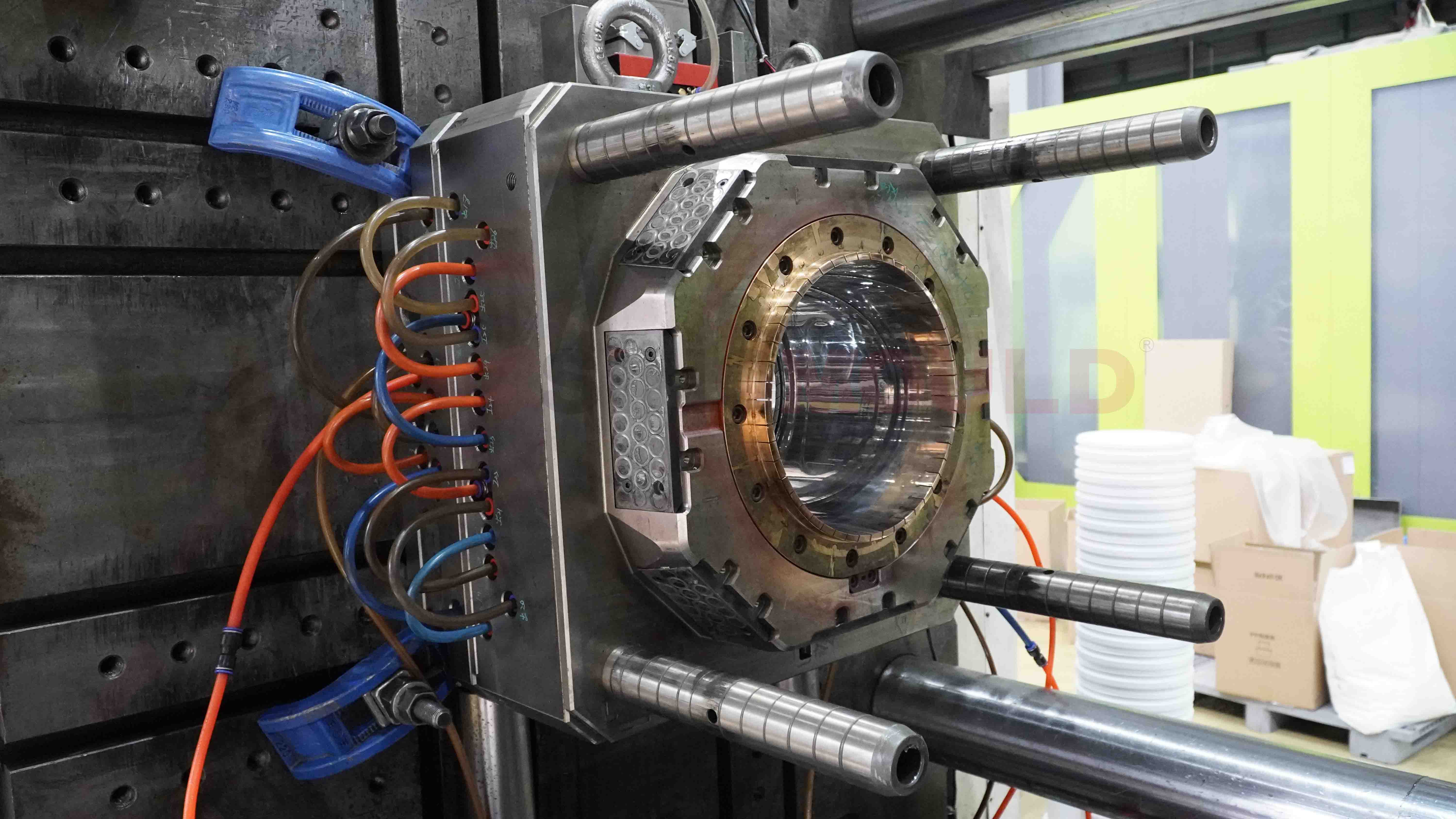

Plastic Paint Bucket Mould

- The Paint Bucket Mould Powered by sinomould.com.

- Single or Multi-cavity mould design is optional.

- Perfect and comprehensive cooling system design, mould always is iced, maximizing shortening the cycle time.

- Durable steel with harden treatment, precision tooling.

- Valve gate hot runner system for ease filling and reduce the injection pressure.

Paint Bucket Mould

Product: 20L bucket mould (786g)

Material: 718H

Cycle time: 14.8s

Description: Paint Bucket Mould is supplied by Sino Mould. Adopting 718H steel, with excellent polishing performance and high hardenability. The mould has a long life; By adopting Anole 1-point needle valve and the design of the exhaust and water circuit, the molding cycle of the paint pail is greatly shortened, which reduces the cost and increases the benefit for the users.

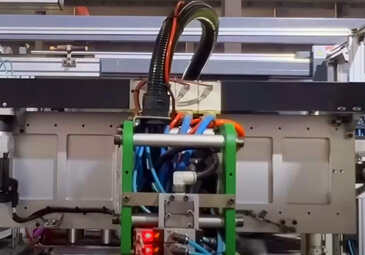

IML System for Painting Bucket Molding Solutions

- If you do not need in mold labeling (IML) robot system, the normal robot is opitional.

Paint Bucket Molding Machine Line Auxiliary Machinery

The drying machine can effectively remove the water in the plastic raw materials to ensure that the raw materials meet the drying requirements, to avoid the defective rate of the paint buckets.

To achieve intelligent automatic supply of plastic raw materials, to ensure the high efficiency and stable operation of the paint bucket production line.

It is designed to be either air-cooled or water-cooled. This series of water at temperature between 7-30℃ with ±1 deviations.

DKM crusher is adopted to recycle all kinds of plastics, including massive, rotundity, strip. It operate importantly in the plastic industry.

Paint Bucket Mould Machine Production Line One-Stop Project Service

- Double production Speed + 30 days delivery + lower cost input=【NO COMPITITORS】

- High stability, accuracy and high speed filling with low noise and vibration.

- With ensuring sealing bucket, pass loading and drop test, achieve strong but lightest bucket manufacturing.

- We offer engineering service in your factory for on-stie installation, operating, training, untill your normal mass production.

Paint Bucket Mould Machine Images

Paint Bucket Mould Machines Running Video

Here are videos of some of our paint pail production lines