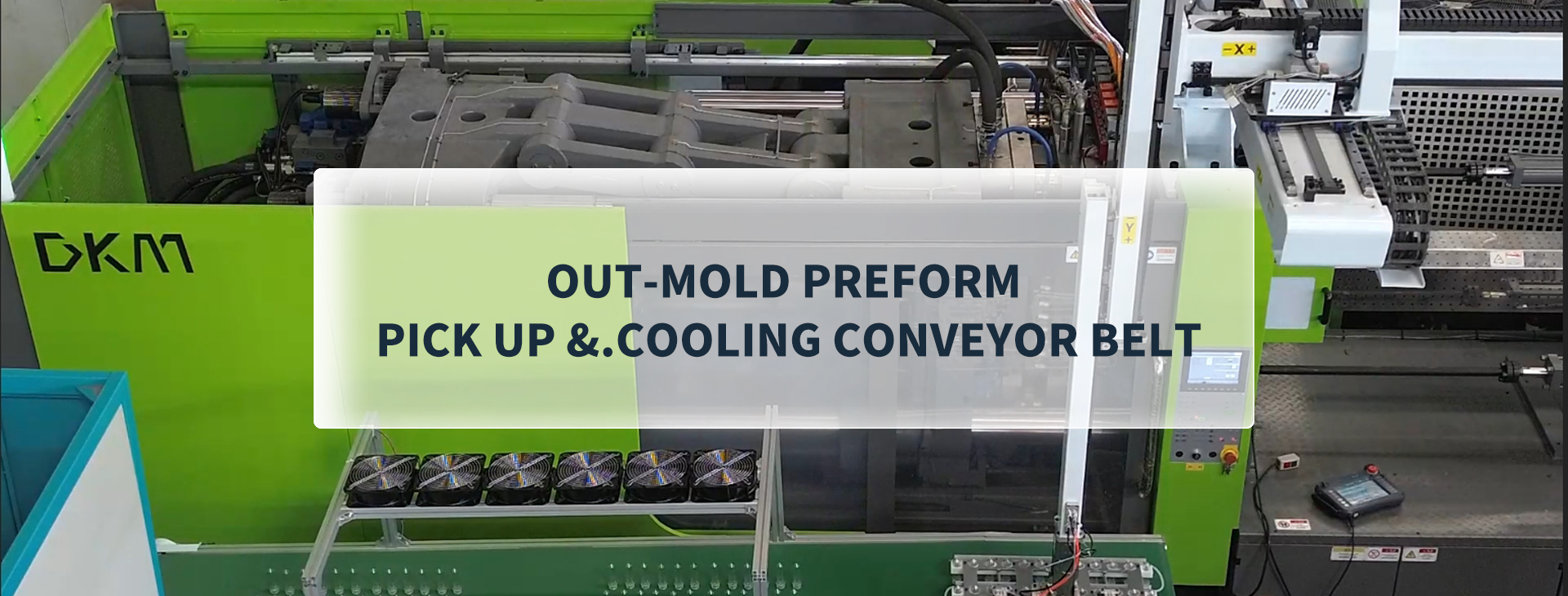

Out-Mold Preform Pick Up &.Cooling Conveyor Belt

After the initial molding cycle, the robotic arm places the hot preforms onto the high-speed Post-Mold Cooling Conveyor. The conveyor then transports them through a meticulously engineered cooling tunnel, featuring multi-zone temperature control and balanced airflow. This process allows the preforms to release heat gradually and uniformly, promoting optimal molecular structure and crystallinity for maximum performance.

Solving Your Core Challenges

- Our Solution: Offload the time-intensive cooling process from the mold, directly reducing your machine's cycle time and unlocking a new level of production capacity.

- Our Solution: Provides a more uniform and gentle cooling environment than in-mold cooling, effectively eliminating internal stresses to create flawless preforms with perfect dimensional stability.

- Our Solution: Shares the thermal load, allowing for optimized heat management across the entire system and lowering the energy cost per unit produced.

Ideal For Your Line:

Whether you’re running high-speed production for water and CSD bottles, or manufacturing high-clarity, high-strength preforms for premium edible oil and personal care containers, our Post-Mold Cooling Conveyor is your key to a competitive edge.