Plastic Injection Molding Machine

WHAT WE OFFER:

DKM IMM standard clamping force is from 90 TONS to 6,000 TONS, offers you a wide range of plastic injection molding machines with precise, qualitative, stable and efficient production.

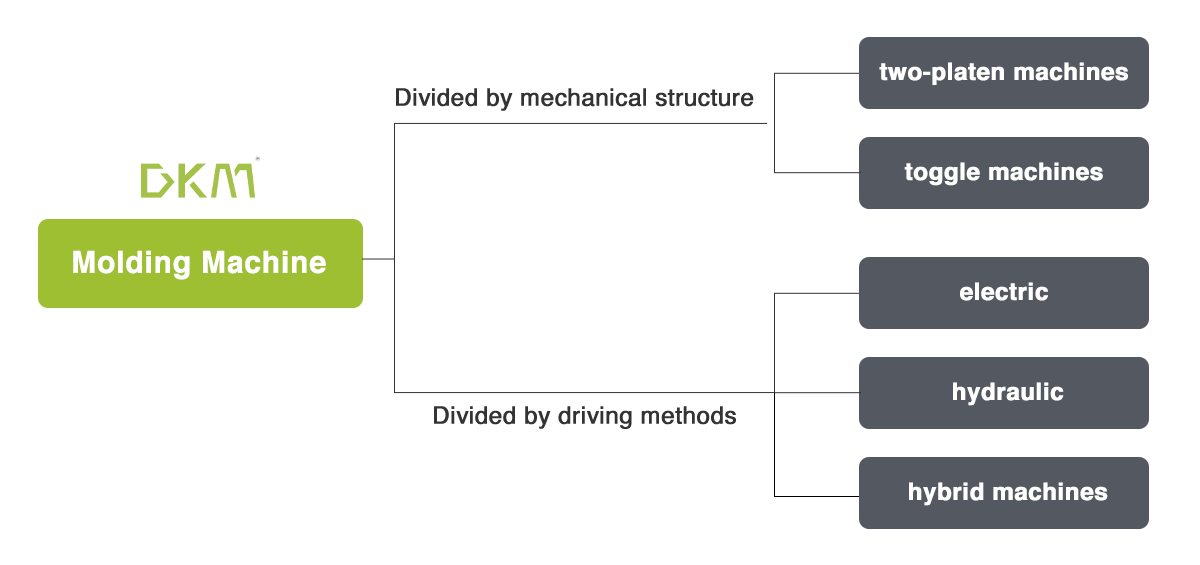

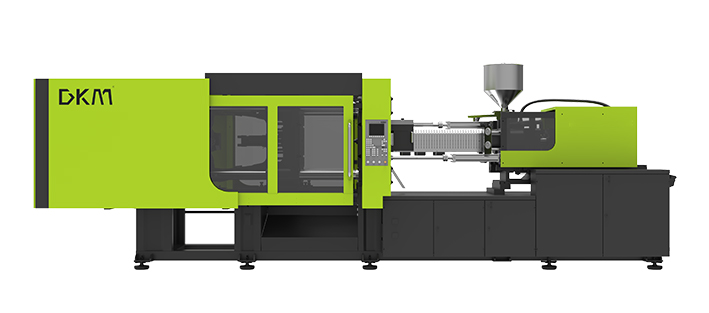

Divided by mechanical structure, DKM injection molding machines have two types: two-platen machines & toggle machines.

Divided by driving methods, DKM injection molding machines have three types: electric, hydraulic, and hybrid machines.

In response to different user needs, we have launched special feature models including high speed thin-wall injection machine, medical special machine, low-inertia energy-saving machine, PET preform special machine, and more with full range of plastic processing technologies.

- Plastic Injection Molding Machine Series Display

Go To Select the Plastic Injection Molding Machine

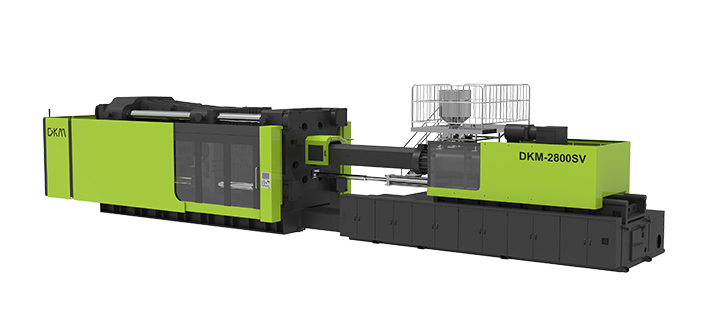

DKM’s two-platen injection molding machines have a compact design. and capable of producing large parts with high precision. The machines use a two-platen clamping system. And this Ensures stability. Reduces the risk of deformation or warping during the molding process. They are equipped with advanced control systems that ensure stable performance. And They Minimize energy consumption, making them an efficient and environmentally friendly choice.

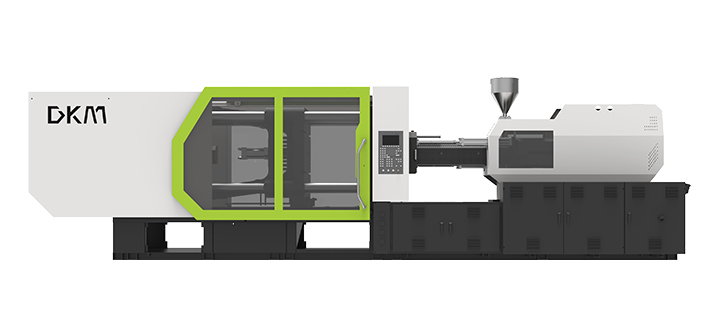

DKM servo series is a high-performance plastic injection molding machine. Designed for accuracy and productivity. These machines are equipped with a robust injection unit, efficient hydraulic system, and advanced control technology, which allow fast and accurate molding. The DKM series is suitable for a wide range of applications.

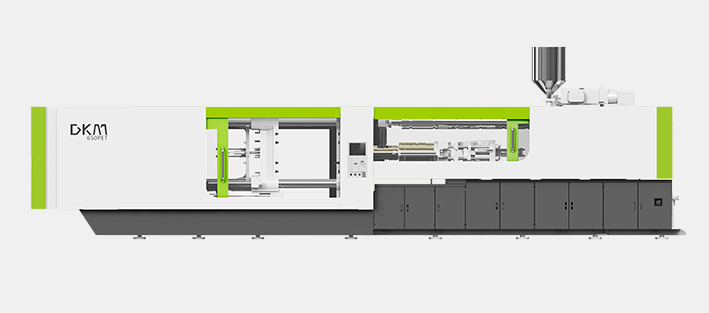

DKM high speed injection molding machines 3 axis linkages realizes material charging, mould opening and ejection at the same time to shorten cycle time and improve production efficiency. With high injection speed and high-response servo-hydraulic system, DKM-HH series high speed injection molding machines are suitable for packaging industry especially thin-wall containers.

These machines are specialized for manufacturing PET preforms. DKM’s PET preform used in the packaging industry for bottles and other containers. The machines are very efficient and accurate. These features include low shear rates, fast cycle times, and high-quality surface finishes. They are also equipped with an advanced material temperature control system, ensuring stable and continuous molding.

DKM offers a range of machines for PVC injection molding applications. This requires specific features, Such as high-temperature control and material stability. These machines are designed to provide high precision control, low energy consumption, and stable performance, making them an efficient and reliable choice for PVC molding applications.

DKM-MX series injection molding machines are designed for making medical equipment and consumables. Considering the strict requirement of cleanness for medical consumables, MX injection molding machines adopt electric ejector cylinder to avoid oil pollution and make clean and precise medical equipment. MX series specialize in the production of a wide range of medical products including but not limited to syringe, test tube, pipette tips, petri dish, etc.

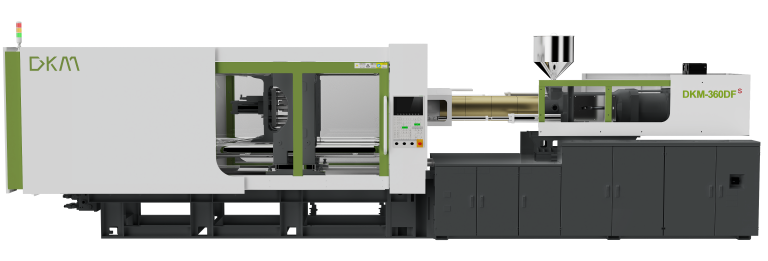

With continued technical upgrades and improvements, DKM has launched the sixth generation of low-inertia thin-wall injection molding machines. DFS series (200-800T), which is the upgraded iteration of DKM’s thin-wall injection molding machines, with complete models available, combining the advantages of high speed, high precision, high efficiency and high energy saving, etc.

DKM full electric injection molding machine (90-460T) is the main action by a separate servo motor as the actuator to complete the injection molding machine.DKM Full-electric injection molding machine is widely used in automotive, electronics, medical, packaging, and other fields, suitable for the production of precision parts, such as medical products like blood collection tubes, luer syringes,etc and high-transparency products like optical lenses, to meet the needs of different industries.

- DKM offers a range of plastic injection molding machine which caters to various industrial needs with a focus on high performance, efficiency, and accuracy. The company is committed to innovation and customer-centricity. And its machines are known for their reliability and durability.

- DKM has more than 20 years of experience in the construction of plastic injection molding production lines, and we have shipped more than 4000 production lines worldwide.

- We provide you with the right equipment, professional injection molding solutions and meticulous personnel training services, so that you can start your own injection molding business in the shortest time, saving you the economic cost of investment, time cost and opportunity cost.

- Focus on the Requirements of Users

There is some general information about the need for DKM machines. Essentials a person who wants to buy DKM should know

- Capacity:DKM machines come in different sizes and have various degrees depending on the intended use. It is essential to determine how much material you need for processing. And choose a machine that meets your needs.

- Durability:DKM machines are designed to be durable and reliable. But it is essential to choose a machine that is built to last. And it can withstand the demands of your specific application.

- Accuracy:Depending on the application, accuracy can be critical to achieving the desired results. DKM machines can offer different levels of accuracy. Therefore, choosing a machine that can provide the level of precision you need is essential .

- Ease of use:DKM machines should be user-friendly and easy to operate with clear instructions and intuitive controls.

- Maintenance:Regular maintenance is essential for DKM machines to function well and extend their lifespan. Choosing a machine that is easy to maintain and has clear instructions is critical.

- Maximize customer value - the right models and injection molding solutions

To meet the needs of customers in various industries for various injection molding products. Includes:

- Packaging products

Liquid packaging: beverage packaging, mineral water bottle packaging, oil bottles, cosmetics bottles Food packaging: crisper box, thin wall containers, food jar Industrial packaging: paint pail, buckets, oil drums.

- Medical device products

Syringe, test tube, blood collection tube, petri dish, pipette, etc

- Logistics products

Turnover box, foldable crate, pallet

- Pipe Fitting Products

PVC screw barrel, PVC pipe fitting, PPR pipe fitting, U-PVC pipe fitting, other special fitting

- Automotive products

car parts, automotive parts.

- Industrial products

Industrial large trash bin (box) underground parts

- Household products

Household appliances, daily necessities, toys

- High precision products

Electronic Components, optical components, mobile phone accessories, electrical components

DKM is committed to developing injection molding technology suitable for the industry according to the production needs and product characteristics of different industries, so that users can obtain absolute advantages in the production cycle and product quality of each injection molding product.

From the selection of injection molding machine consultation to the production of orders, shipping and after-sales service, there will be a special person to provide you with service, avoid wasting time ineffective communication, and provide you with accurate and rapid injection molding equipment in the fastest time.

DKM owns more than 20 years of experience in the injection molding production line construction.And have delivered more than 4000 turnkey solutions of plastic molding production lines, accumulating much experience, technology and data of injection molding.

By choosing DKM one-stop turnkey supply,you can easily reduce unnecessary tuition fees.

We’ll help saving your financial,time and opportunity investment.

Carry out in-depth research and development on various performance of the machine, including injection accuracy, machine reaction and operation time, stable operation of the machine, and energy saving of the machine, to help customers save energy consumption, reduce maintenance costs, improve production capacity and reduce production costs. Maximize profits.

- DKM Machine Culture and Concept

DKM is a global manufacturer of plastic injection molding machines. Its culture and concept are focused on innovation, reliability, and customer-centricity.

At the core of DKM culture is a focus on developing new technologies and solutions. It meets the evolving needs of the industry. The company has a strong commitment to research and development. A team of engineers and technicians is dedicated to designing and improving our products.

Reliability is another essential aspect of DKM culture. In which the focus is on providing high-quality machines. That is efficient, durable, and easy to maintain. The company’s devices are known for their robust design, precise control, and stable performance. Which helps reduce downtime and improve productivity.

An essential part of DKM culture is the focus on understanding and meeting the specific needs of our customers. The company works closely with its customers. Therefore _ He should provide a suitable solution. Which are designed to improve efficiency, reduce costs and increase product quality.

Additionally, DKM is committed to sustainability and social responsibility. It focuses on reducing its environmental impact, promoting diversity and inclusion, and supporting the communities in which it operates.

- Conclusion

In conclusion, DKM plastic injection molding machine offer high-quality, efficient, and reliable solutions for plastic manufacturing needs. With a range of models and options to choose from, DKM provides customized solutions to fit specific production requirements. The advanced technology and rigorous quality control processes ensure that DKM machines can deliver consistent and precise results. Overall, DKM plastic injection molding machines are a valuable investment for any plastic manufacturing operation seeking to optimize productivity and profitability.

Tell Us Your Needs

Please contact us directly and we will develop the right injection molding machine solution for you according to your needs.

Low Inertia Injection Molding Machine

Milk Cap Molding-High Speed Injection Molding Machine

IML Ice Cream Box-High Speed Injection Molding Machine