High-Speed Bottle Cap Production Line

High-Speed Bottle Cap Production Line

Our cutting-edge High-Speed Bottle Cap Production Line integrates advanced automation, precision engineering, and intelligent design to deliver unmatched performance in cap manufacturing. Whether for beverages, pharmaceuticals, cosmetics, or industrial applications, this line ensures rapid, reliable, and consistent production of high-quality caps tailored to global standards.

Applications Across Industries

- Beverages: Screw caps for water, carbonated drinks, juices.

- Pharmaceuticals: Child-resistant and tamper-evident closures.

- Food Packaging:Spice jars, oil bottles, canned goods.

- Cosmetics:Luxury perfume caps, cream jar lids.

- Industrial: Chemical containers, automotive fluid caps.

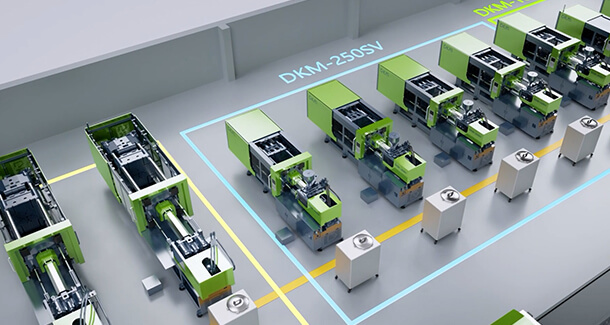

High-Speed Cap Injection Molding Machine

High energy saving

compared with conventional hydraulic injection molding machines,20-80% energy can be reduced.

Molding stability

Compared with conventional injection molding machines,repeat-ability is greatly improved due to servo motor closed-loop control.

Quick response

Featuring a dynamic servo motor with a response time of only 0.05sec.

Quiet operation

The machine runs at a much lower noise level, particulary in low speed applications.

Reliable holding pressure

Compared with traditional hydraulic machine the holding pressure is more stable and the dwell time has been much extended.

Better oil temperature stability

The servo system only delivers hydraulic oil as it is needed for various functions,which prevents unnecessary generation of heat and substantially reduces oil cooling requirements.

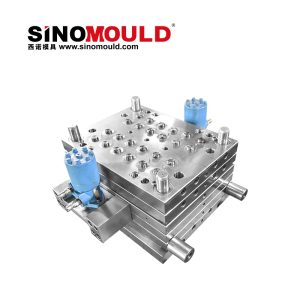

High-Speed Cap Mould

- Meet high-quantity productivity ,26000-30000 PCS/hour

- Full hot runner system with Germany heater

- Interchangeable core and cavity,easy for maintainence

- With Keba PLC, realize humaniz

For the cap mould, we could make flip-top cap mould, water cap mould, Juice cap mould, spray cap mould which could suit for different bottle size.

Mould Name: Cap/PET Preform Mould

Product Size: PCO28mm

Product Description: 2g caps for water packaging industry

Mould Cavity: 72 Cavity

Mould Size: 1320*620*759mm

Mould Main Material: S136 stainless steel with HRC48-50 (ASSAB )

Mould Injection System: hot runner Gate(Anole brand)

Mould Cycle Time: 5 Seconds

Delivery Time: 60 working days

Highlights of DKM High-Speed Cap Production Line

Based on your annual production quantity requirements, we will recommend the most suitable machines, moulds, and related equipment. We will provide you with an outstanding project quotation book that includes all the budget details.

After confirming the details, we will design a detailed layout for your workshop, including electricity, water, air lines, machine and equipment positioning, raw material storage, and finished product warehouse.

We will start the production of machines, moulds, and all related equipment. Once ready, we will test them in our facility to ensure smooth and stable operation.

Upon delivery to your workshop, our service engineers will assemble the machines, provide operation training, and support you until you achieve normal mass production.