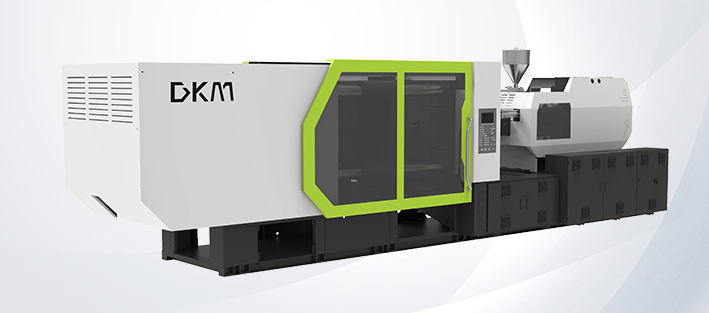

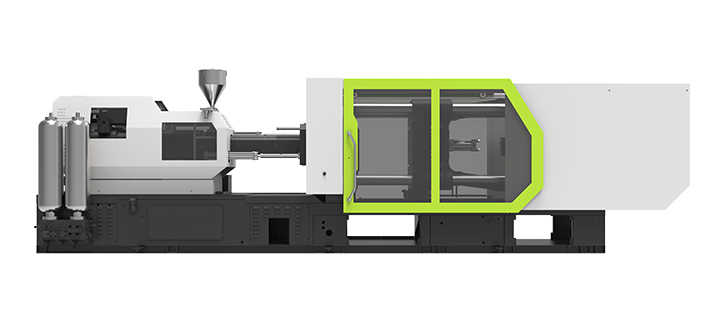

High Speed Injection Molding Machine DKM-HH Series

Welcome to the world of precision and power with Dakumar’s exceptional range of injection molding machines! Look no farther if you want to fully realise the possibilities of plastic injection moulding. Our cutting-edge equipment, which can handle projects weighing anywhere between 200 tonnes and an incredible 1300 tonnes, offers unmatched performance and efficiency, revolutionising the way you realise your ideas.

Imagine being able to precisely generate high-quality parts while moulding complicated shapes and complex geometries. You can achieve that thanks to our selection of injection moulding machines. We have the equipment to meet your individual needs, ranging from our adaptable 200-ton machines, ideal for smaller production runs or complicated components, to our strong 130-ton machines, built to handle high-volume production.

Let’s delve in details to know more about DKM fast Speed Injection Molding Machine (200tons-1300tons).

Clamping Force

2000-13000kN

Structure

Toggle(Three-Platen)

Machine Drive

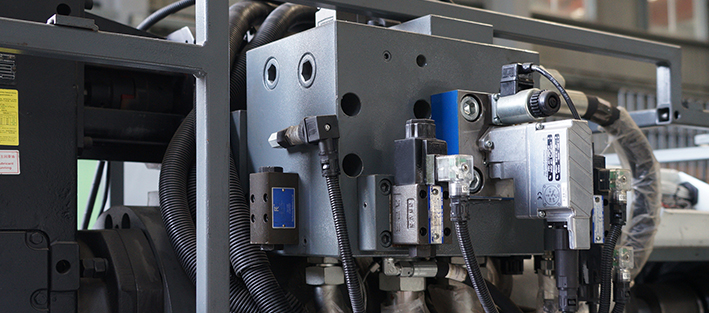

Hydraulic Servo System

- DKM Fast Speed Injection Molding Machine (200Ton - 1300Ton)

The DKM Fast Speed Molding Machine series, ranging from 200 tons to 1300 tons, offers a range of outstanding features that set them apart in the industry. These machines are designed to deliver exceptional performance, precision, and reliability, ensuring optimal results for your molding needs. With lightning-fast response times, tight tolerance control, and robust construction, it enable rapid production, high-quality output, and uninterrupted operation. Additionally, their customizable options allow for flexibility, empowering you to adapt to changing market demands. Experience the power of DKM and elevate your injection molding process to new levels of efficiency and success.

- Wide range of tonnage options available, from 130 tons to 4000 tons

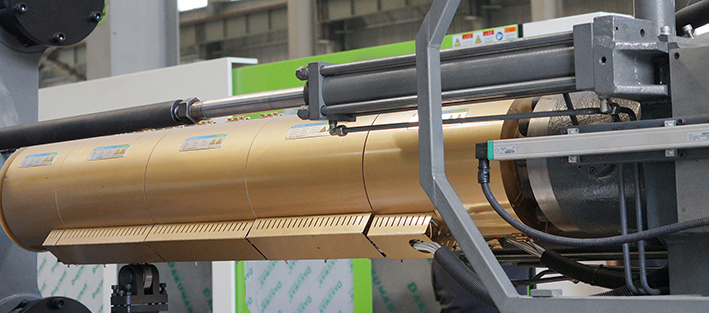

- Utilizes advanced servo motor technology for precise and efficient operation

- High-speed injection for improved productivity

- Energy-efficient design reduces power consumption

- Exceptional precision and repeatability for consistent quality

- Versatile machine capable of handling various types of plastics

- Robust construction for durability and longevity

- User-friendly interface for easy operation and monitoring

- Advanced control system for precise parameter adjustment

- Safety features to ensure operator protection

- Optional customization and configuration to meet specific production requirements

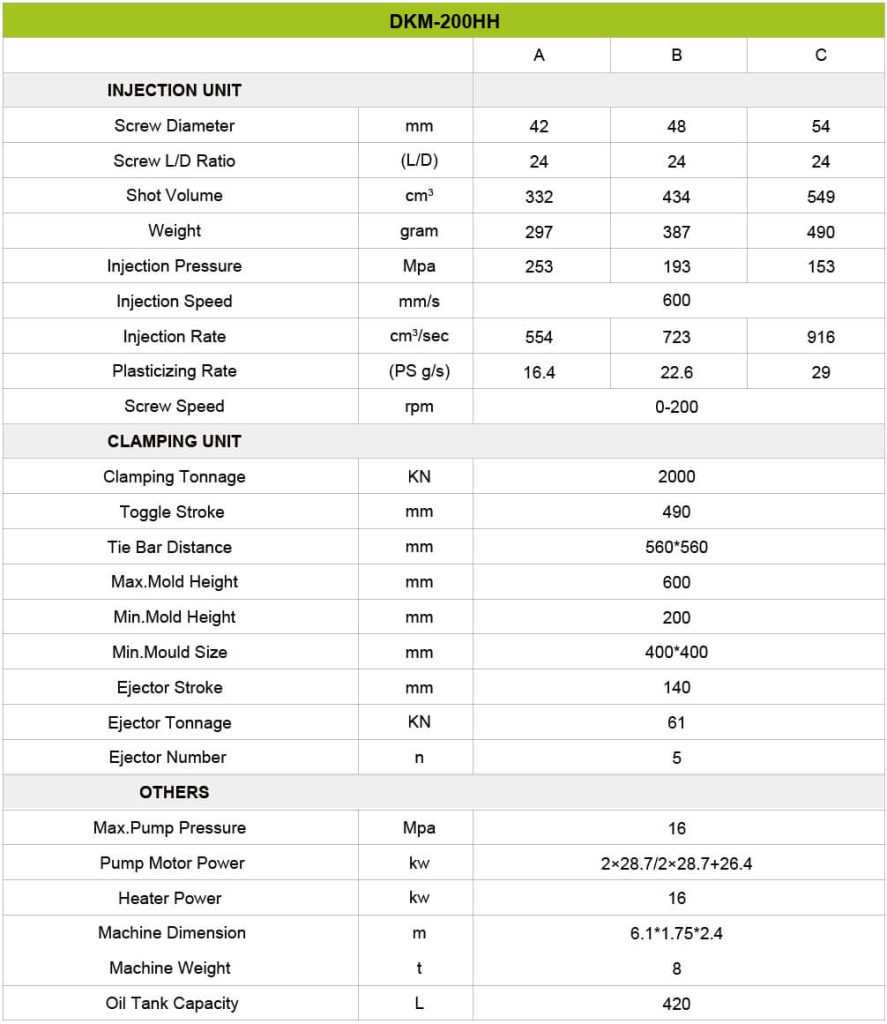

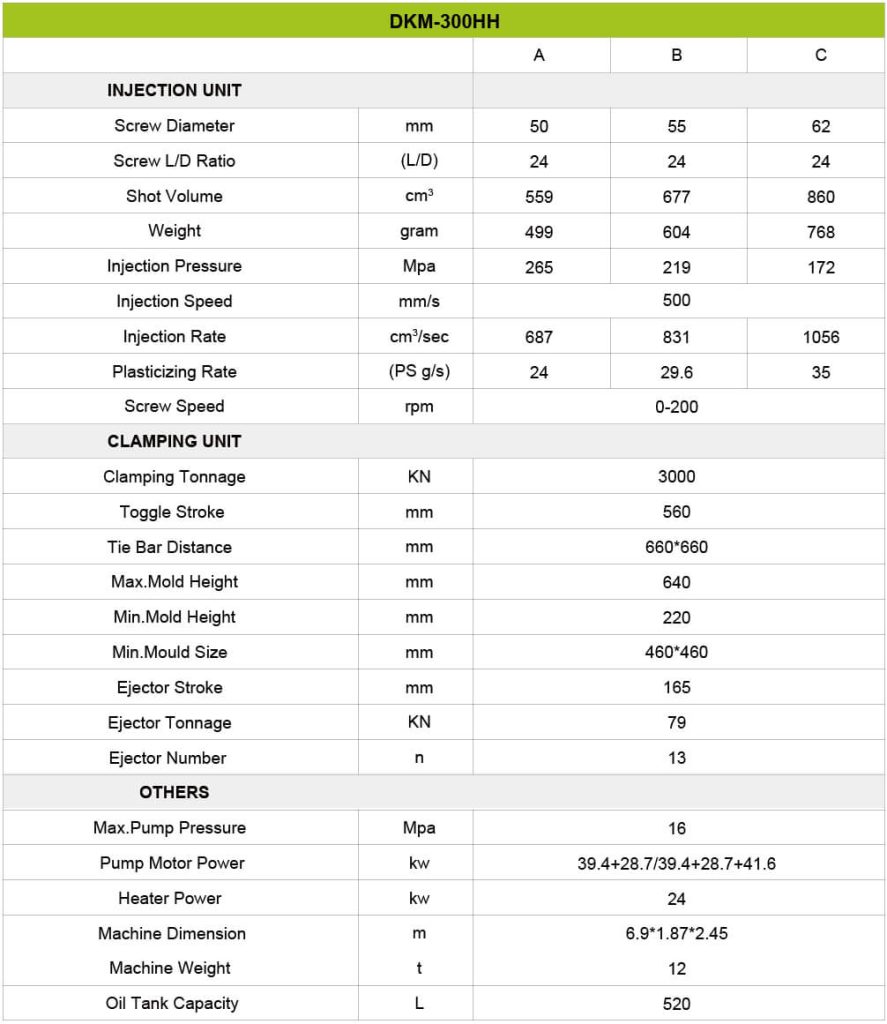

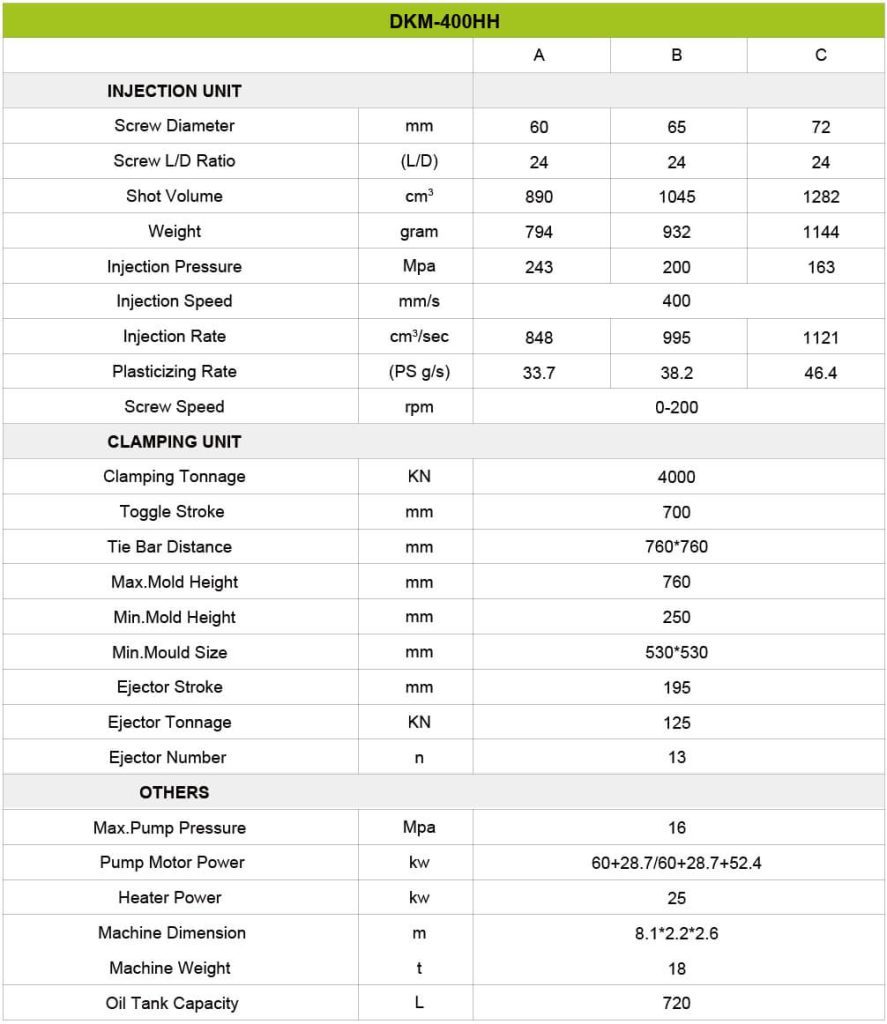

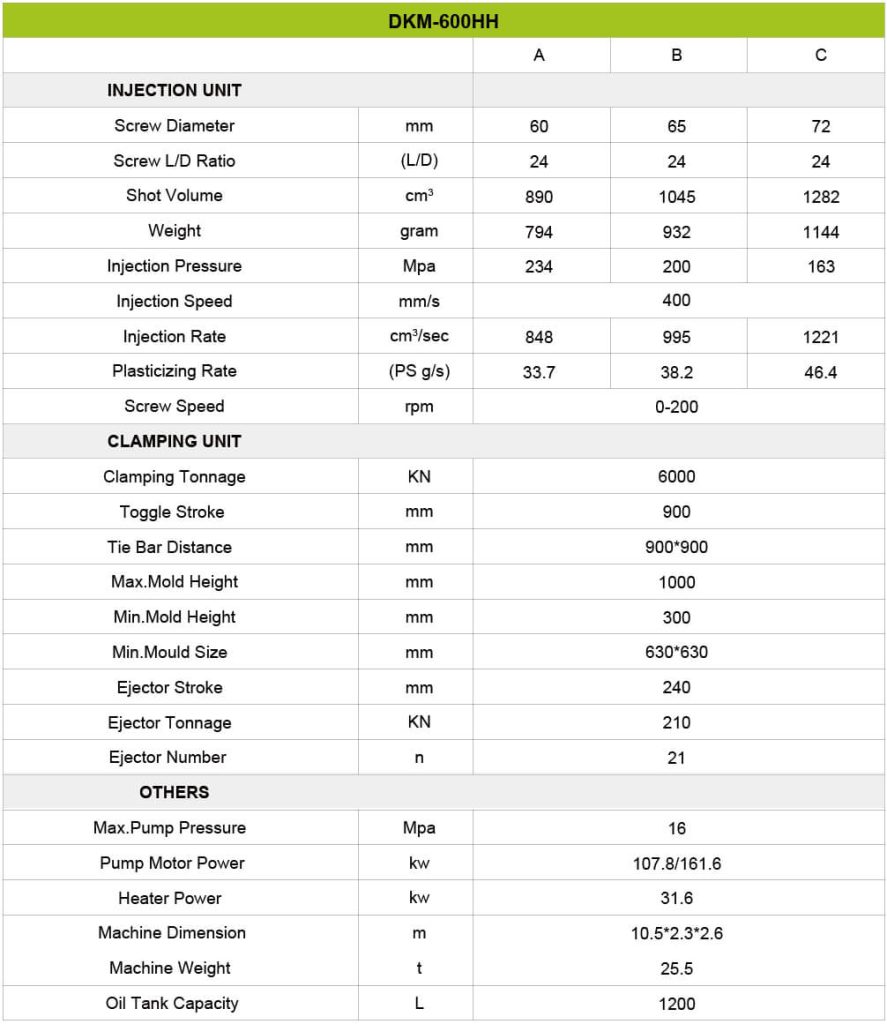

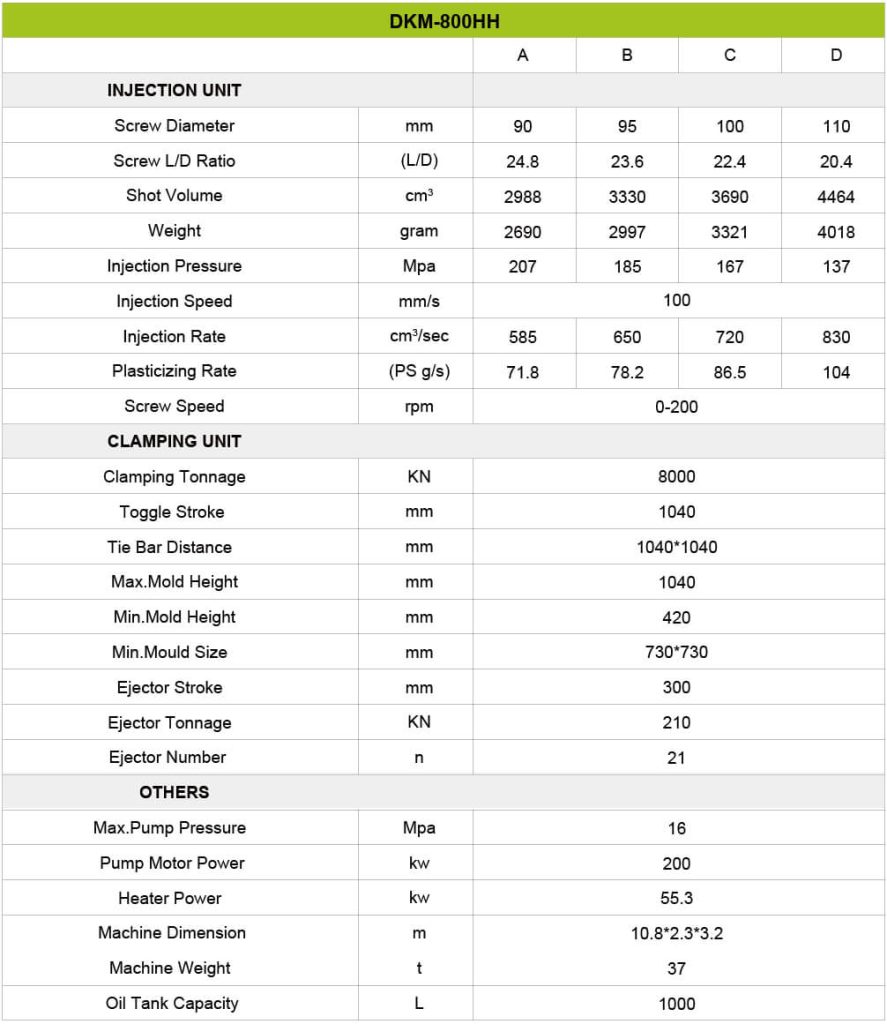

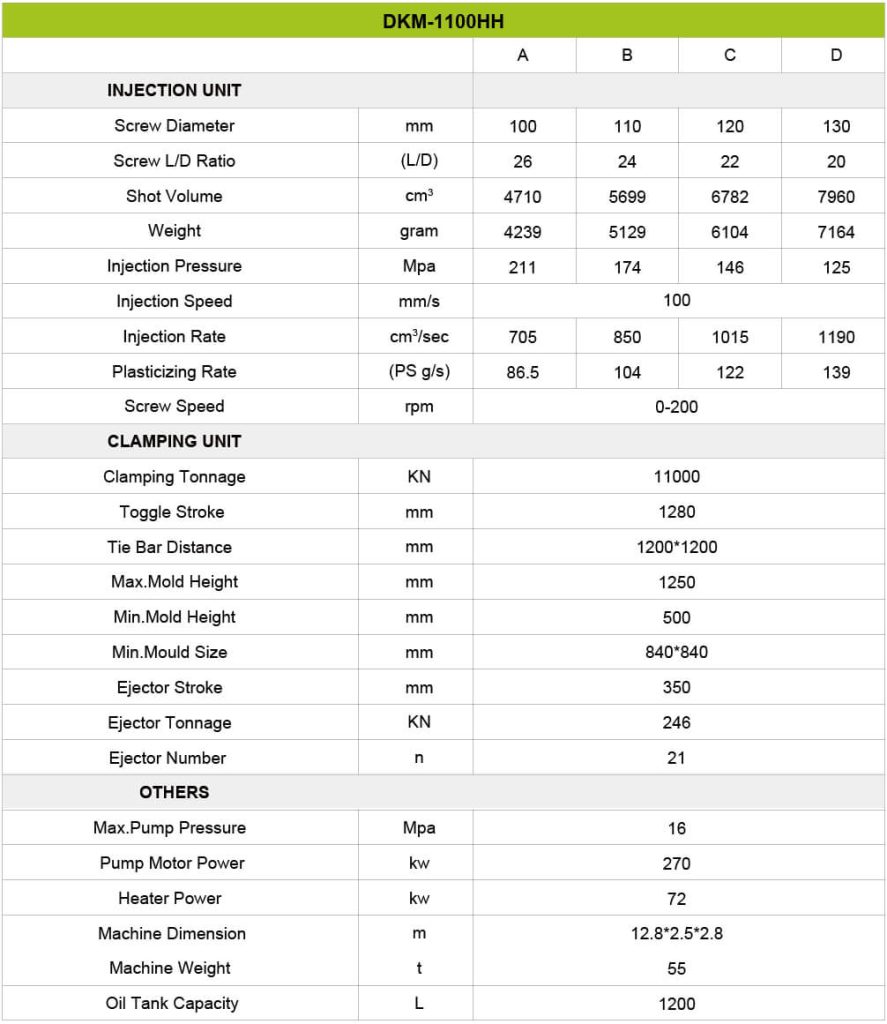

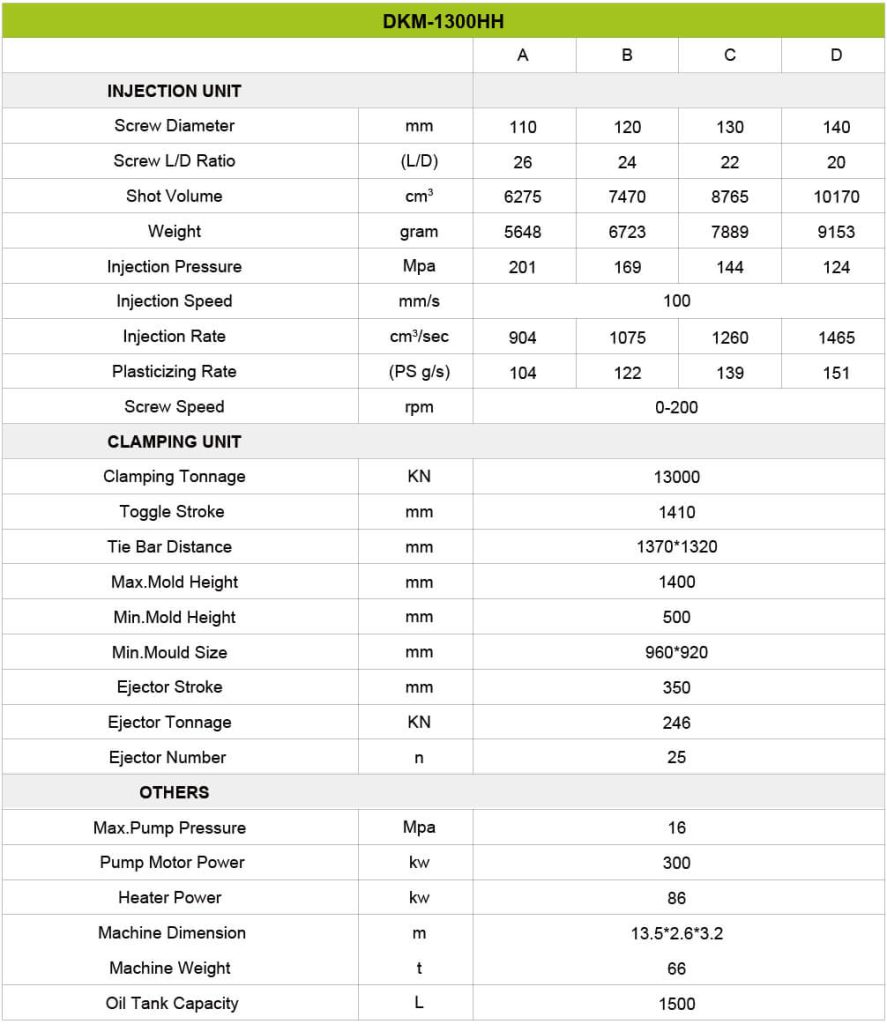

- HH Fast Injection Molding Machine Specification

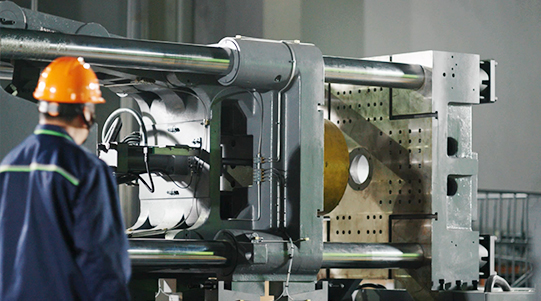

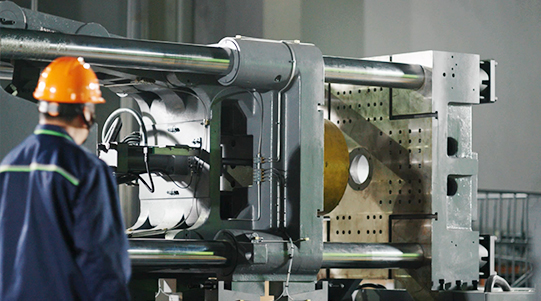

- DKM fast Speed Injection Molding Machine (DKM-HH SERIES) in Operation

When it comes to operating the Molding Machine series (ranging from 200 tons to 1300 tons), Dakumar (“DKM”) has engineered these machines to excel in the field of plastic injection molding. The performance and efficiency of these cutting-edge machines are astounding throughout the production cycle. With their advanced technology and precise control systems, DKM Fast Speed machines ensure smooth and seamless operation. From the initial mold setup to the final ejection of the perfectly formed plastic parts, these machines exhibit exceptional speed, accuracy, and reliability. Whether you are producing intricate components or large-scale productions, the Machines provide the reliability and precision required for successful plastic molding.

- Advantages of using DKM fast Speed Injection Molding Machine (200tons-1300tons)

When it comes to the advantages of utilizing the Machine series (ranging from 200 tons to 1300 tons), there are numerous benefits that set these machines apart. Here is a overview of the advantages of using DKM Fast Molding Machines:

The Machines are engineered for rapid production. With advanced servo motor technology and optimized hydraulic systems, these machines offer lightning-fast response times. This enables quick mold opening and closing cycles, reducing overall cycle times and increasing production output. The high-speed capabilities of these machines allow for improved efficiency and shorter lead times, giving you a competitive edge in the market.

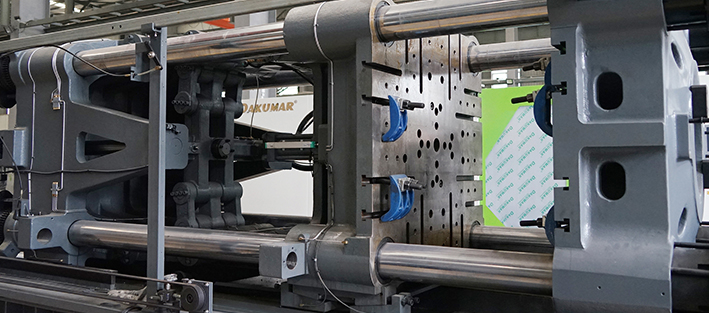

Achieving precise and consistent results is crucial in injection molding. The Fast Speed machines boast excellent precision and repeatability. Their advanced control systems and robust construction ensure tight tolerance control, delivering high-quality plastic parts with consistency. Whether you require intricate components or large-scale production runs, these machines can meet your exact specifications, resulting in superior product quality.

With the DKM Fast Speed Machines, you can significantly boost your productivity. You may optimize your production process by combining fast operation, exact control, and individualized options. These machines enable greater industrial efficiency by decreasing cycle times and raising output. Increased profitability and better overall business success follow from this.

Our company is renowned for its commitment to reliability, and the Fast Speed series is no exception. These machines are built with durability in mind, using high-quality components and robust construction. They can withstand the demands of continuous operation without compromising performance. With Fast Speed machines, you can rely on uninterrupted production, minimizing downtime and maximizing your return on investment.

DKM understands the importance of versatility in the injection molding industry. The Fast Speed series offers a wide range of customization options to cater to diverse production needs. From multiple injection unit configurations to flexible clamping mechanisms, these machines can be tailored to match specific requirements. This versatility allows you to explore new product possibilities and adapt to changing market demands with ease.

Energy efficiency is a crucial factor in today’s ecologically conscious world. DKM Fast Speed Injection Molding Machines are designed to optimize energy consumption. They incorporate energy-saving features such as servo motor technology and advanced control algorithms, reducing power consumption without compromising performance. By minimizing energy waste, these machines contribute to sustainable manufacturing practices and help lower operational costs.

DKM takes pride in providing comprehensive support and service to its customers. From machine installation and setup to ongoing technical assistance, their team of experts is dedicated to ensuring a seamless experience. They offer training programs, maintenance support, and spare parts availability, guaranteeing that your investment is protected and your operations run smoothly.

- What You Need to Know About DKM Fast Speed Injection Molding Machine (200Ton-1300Ton)

DKM One Stop Solution

When considering the Fast Molding Machine series, which ranges from 200 tons to 1300 tons, there are a few key points to know about these machines:

Speed and Efficiency:

The machines are specifically designed for rapid production. They incorporate advanced servo motor technology and optimized hydraulic systems to achieve fast mold opening and closing cycles. This results in reduced cycle times and increased production output, enhancing overall efficiency.

Precise and Consistent Results:

These machines are engineered to deliver tight tolerance control, ensuring precise and consistent molding results. The advanced control systems and robust construction contribute to high-quality plastic parts with repeatability, meeting the strictest requirements and specifications.

Versatility and Customization:

The Fast Speed series offers a range of customization options to suit various production needs. This includes multiple injection unit configurations and flexible clamping mechanisms, allowing manufacturers to tailor the machines to their specific requirements. The versatility of these machines enables versatility in product design and production flexibility.

Reliable and Durable Construction:

Robust Construction for Longevity

High-Quality Components for Reliable Performance

Built for Continuous Operation and Minimal Downtime

Durability to Withstand Demanding Production Environments.

Why Should Consider Buying DKM?

When considering the purchase of a plastic injection molding machine , there are several compelling reasons to consider buying DKM. Here are some headings highlighting the key factors that make this company a worthwhile choice:

Servo Motor Injection Molding Machines are designed to handle various types of plastics, including both commodity and engineering-grade materials. This versatility allows you to cater to diverse market demands and expand your product offerings across different industries.

These machines are built with robust construction, ensuring durability and longevity. The sturdy design can withstand the demands of high-pressure injection molding operations, reducing downtime and maintenance costs.

The machine lineup covers a broad range of tonnage options.from 80 tons to 4000 tons. This versatility allows you to selectthe appropriate machine size based on your specificproduction requirements, whether you need to produce smallcomponents orlarge-scale items.

These machines utilize advanced servo motor technologywhich provides precise and efficient operation. Servo motorsoffer excellent control over the injection process, resulting inconsistent and high-quality outputs.The dynamic control andresponsiveness of servo motors enable improved precision.repeatability.and reduced waste

Servo Motor Injection Molding Machines offer hiqh-speed injection capabilities, which contribute to improved productivityFaster injection speeds help minimize cycle times, allowing youto produce more parts in less time. This increased efficiencytranslates into higher production output and reduced costs.

Servo motor technology is known for its energy efficiency.These machines optimize power consumption by adjusting themotor speed based on the required load. They use less energyas a consequence than conventiona hydraulic svstems. whichresults in financial savings and a less environmental effect.

The high precision and reproducibility of the injection moldingprocess are made possible by the precise control provided byservo motors. This is especially important for sectors that needprecise tolerances and high-quality end products. Consistentquality output minimizes rejects and rework, leading toimproved overall efficiency and customer satisfaction.

Comprehensive Support and Service

Professional Installation and Setup Support

Ongoing Technical Support for Smooth Operation

Availability of Spare Parts for Hassle-Free Maintenance

Established Reputation and Industry Experience

Proven Track Record of Success

Knowledge and Proven Track Record in Plastic Injection Molding

Recognized for Innovation and Quality

Value for Investment

Optimal Return on Investment

Competitive Pricing with Considerable Features and Benefits

Increased Productivity and Efficiency for Cost Savings

Long-Term Reliability and Performance

Superior Performance and Efficiency

Advanced Technology for Enhanced Performance

Lightning-Fast Speed for Rapid Production

Tight Tolerance Control for Precise and Consistent Results

Optimized Hydraulic Systems for Efficient Operation

Versatility and Customization Options

Wide Range of Customization Options to Meet Unique Requirements

Multiple Injection Unit Configurations for Flexible Production

Flexible Clamping Mechanisms for Adaptability

Versatile Solutions for a Variety of Plastic Injection Molding Applications

Energy Efficiency and Sustainability

Energy-Saving Features for Reduced Power Consumption

Eco-Friendly Manufacturing Practices

Cost Savings through Energy Efficiency

Contribution to Sustainable Manufacturing

Comprehensive Support and Service

Professional Installation and Setup Support

Ongoing Technical Support for Smooth Operation

Availability of Spare Parts for Hassle-Free Maintenance

Established Reputation and Industry Experience

Proven Track Record of Success

Knowledge and Proven Track Record in Plastic Injection Molding

Recognized for Innovation and Quality

Value for Investment

Optimal Return on Investment

Competitive Pricing with Considerable Features and Benefits

Increased Productivity and Efficiency for Cost Savings

Long-Term Reliability and Performance

Superior Performance and Efficiency

Advanced Technology for Enhanced Performance

Lightning-Fast Speed for Rapid Production

Tight Tolerance Control for Precise and Consistent Results

Optimized Hydraulic Systems for Efficient Operation

Versatility and Customization Options

Wide Range of Customization Options to Meet Unique Requirements

Multiple Injection Unit Configurations for Flexible Production

Flexible Clamping Mechanisms for Adaptability

Versatile Solutions for a Variety of Plastic Injection Molding Applications

Energy Efficiency and Sustainability

Energy-Saving Features for Reduced Power Consumption

Eco-Friendly Manufacturing Practices

Cost Savings through Energy Efficiency

Contribution to Sustainable Manufacturing

Competitive Pricing

DKM offers competitive pricing for the DKM-HH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

Provide Complete Supporting Equipment and Service for Your Injection Molding Machine

DKM One Stop Solution

24Hours Services

Training Equipment Maintenance And System Upgrade

- Conclusion:

In conclusion, DKM is a compelling choice when it comes to purchasing a plastic molding machine. With its superior performance, efficiency, and advanced technology, DKM machines offer rapid production, tight tolerance control, and precise results. The reliable and durable construction ensures long-lasting operation with minimal downtime. The versatility and customization options cater to diverse production needs, allowing for flexibility in meeting specific requirements. Our machines are designed with energy efficiency in mind, contributing to sustainable manufacturing practices and cost savings. The comprehensive support and service provided by DKM ensure a seamless experience, from installation to ongoing technical assistance. With its established reputation, industry experience, and value for investment, DKM stands out as a trusted name in the injection molding industry. Consider investing to elevate your production capabilities and achieve outstanding results in plastic injection molding.