Full-Electric Injection Molding Machine

DKM full electric injection molding machine (90-460T) is the main action by a separate servo motor as the actuator to complete the injection molding machine.DKM Full-electric injection molding machine is widely used in automotive, electronics, medical, packaging, and other fields, suitable for the production of precision parts, such as medical products like blood collection tubes, luer syringes,etc and high-transparency products like optical lenses, to meet the needs of different industries.

Clamping Force

900KN-4600KN

Structure

toggle type (three-plate type)

Machine Drive

servo motor system

- Comparison between DKMand other competitors

1.High injection pressure combined with high injection volume makes it applicable to both the production of high-precision products like thin-walled ones and products with large volumes/weights. It has a wide range of applications.

2.A relatively high injection speed can shorten the molding cycle. Meanwhile, DKM fully electric machines are energy-efficient and low in power consumption, which helps reduce production costs.

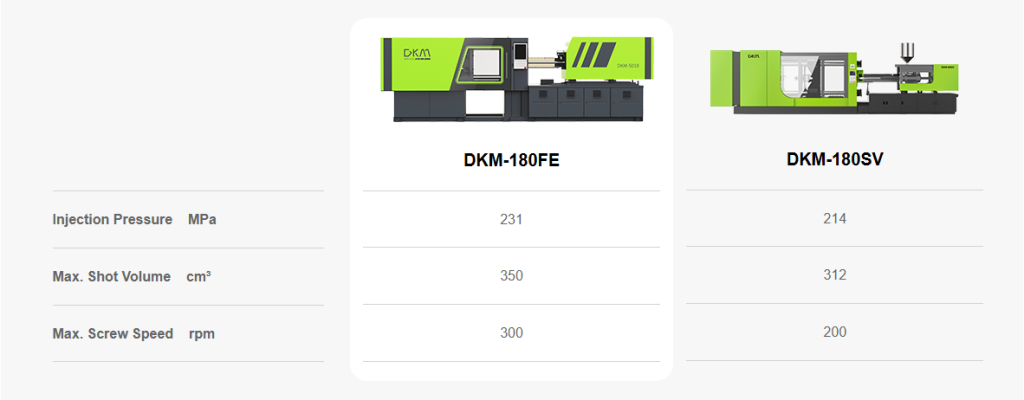

- Comparison between DKM FE series and SV traditional hydraulic series

1. High injection pressure is more suitable for projects of thin wall, complex structure or high precision products.

2. High screw rotation speed shortens the plasticization time, enhancing plasticization efficiency.

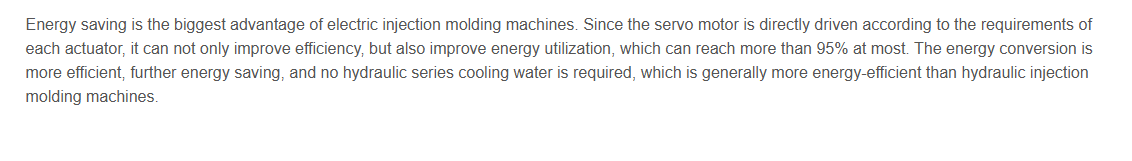

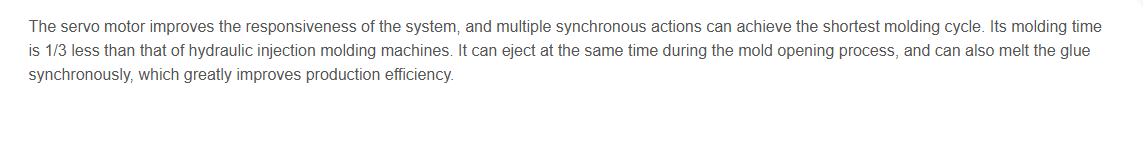

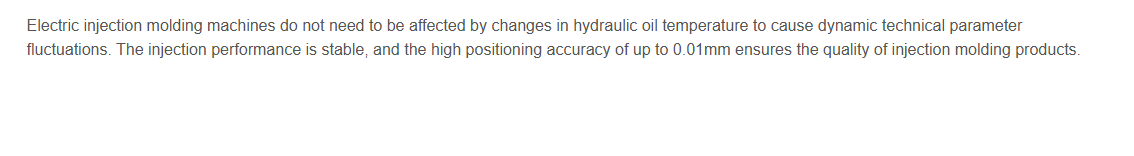

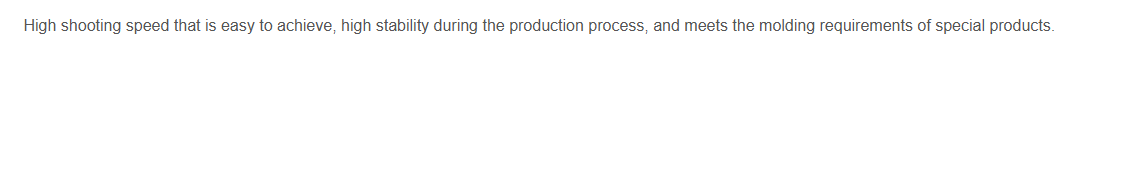

- Advantages FE Series of Full-Electric Injection Molding Machine:

- Full-Electric Injection Molding Machine Features

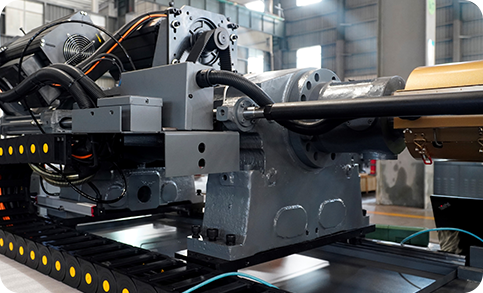

Entire structure

The entire structure features a modular design that ensures high performance and can be organized flexibly based on demands,allowing it to adapt to a wider range of production scenarios.

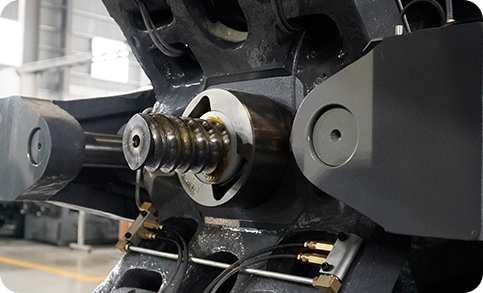

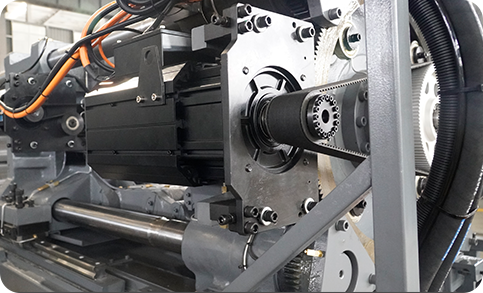

Injection unit

Injection unit adopts inline single-screw design, with key components processed by precision machining centers to ensure that the screw under the right working state without any eccentric load,thus greatly extending the service life of the ball screw.

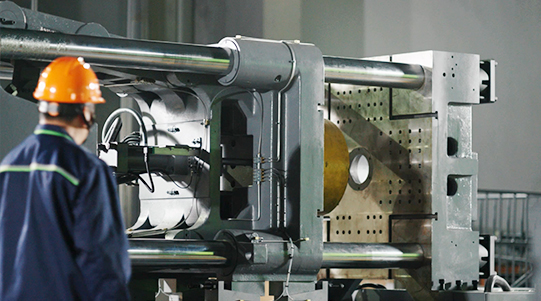

Mold clamping

The high-rigidity clamping mechanism adopts a computer-optimized five-point diagonal toggle design, ensuring clamping rigidity while accommodating sufficient mold-opening space. The moving platen design rivals that of direct-clamp injection molding machines, ensuring central pressure on the platen. This maintains balanced force on the molds and extends their lifespan. The clamping force is stable and the mold-opening position has good repeatablity. The ejection position is precise, which is convenient for the robot to take out the products and easy to realize automation.

Electrical control

Equipped with Techmation SANDAL II all-electric specialized control computer, using NET and CAN communication. It provides a good man-machine interface with its 15-inch high-definition computer display. With an Efficient and stable communication system. The electric system, motor and drive are integrated by Techmation, facilitating communication between axes and ensuring whole system stability.

DKM One Stop Solution

DKM one stop solution helpyou reduce unnecessarytuition fees, saving youfinancial costs time costsand opportunity costs

The reasons to choose DKM DFS series high-speed machine

If you are considering purchasing a DKM-DFS series thin-wall injection moulding machine, DKM offers the following advantages:

Rich injection moulding experience and industry knowledge

With more than 15 years of experience in the production of injection moulding machines, DKM can provide users with high-quality, reliable and intelligent injection moulding equipment. The company has a team of experienced engineers and technicians, who can provide you with perfect pre-sales, in-sales and after-sales services during the whole process of your production.

Versatility and Customisation Options

A wide range of customisation options to meet users’ unique production requirements for flexible production and a flexible clamping mechanism. DKM provides various injection molding solutions for different plastic parts.

High quality and high performance

The DFS series of high-speed machines can be used in a wide range of applications for the production of plastic products. DKM uses high-quality components and advanced technology to ensure stable and smooth machine operation.

Service & Support

DKM Injection Moulding Machines provides comprehensive service and support to our customers, including installation, training, maintenance and repair services. We have several service centers around the world to facilitate on-site help and support for domestic and international users.

Competitive Pricing

DKM offers competitive pricing for the DKM-DH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

Provide Complete Supporting Equipment and Service for Your Injection Molding Machine

DKM One Stop Solution

24Hours Services

Training Equipment Maintenance And System Upgrade

- Conclusion:

Full-electric injection molding machines have significant advantages in energy efficiency, performance, precision, clean production, maintenance cost and environmental sustainability. They provide customers with precise, stable and intelligent solutions for efficient production, making them an ideal choice for the transition of modern manufacturing towards smart and eco-friendly practices. The full-electric injection molding machines are easy to realize automation and intelligence, which is in line with the development trend of modern industry 4.0. This facilitates the implementation of unmanned operations, enhancing production efficiency and flexibility. With technological advancements and decreasing costs, the market potential for full-electric injection molding machines is extensive.