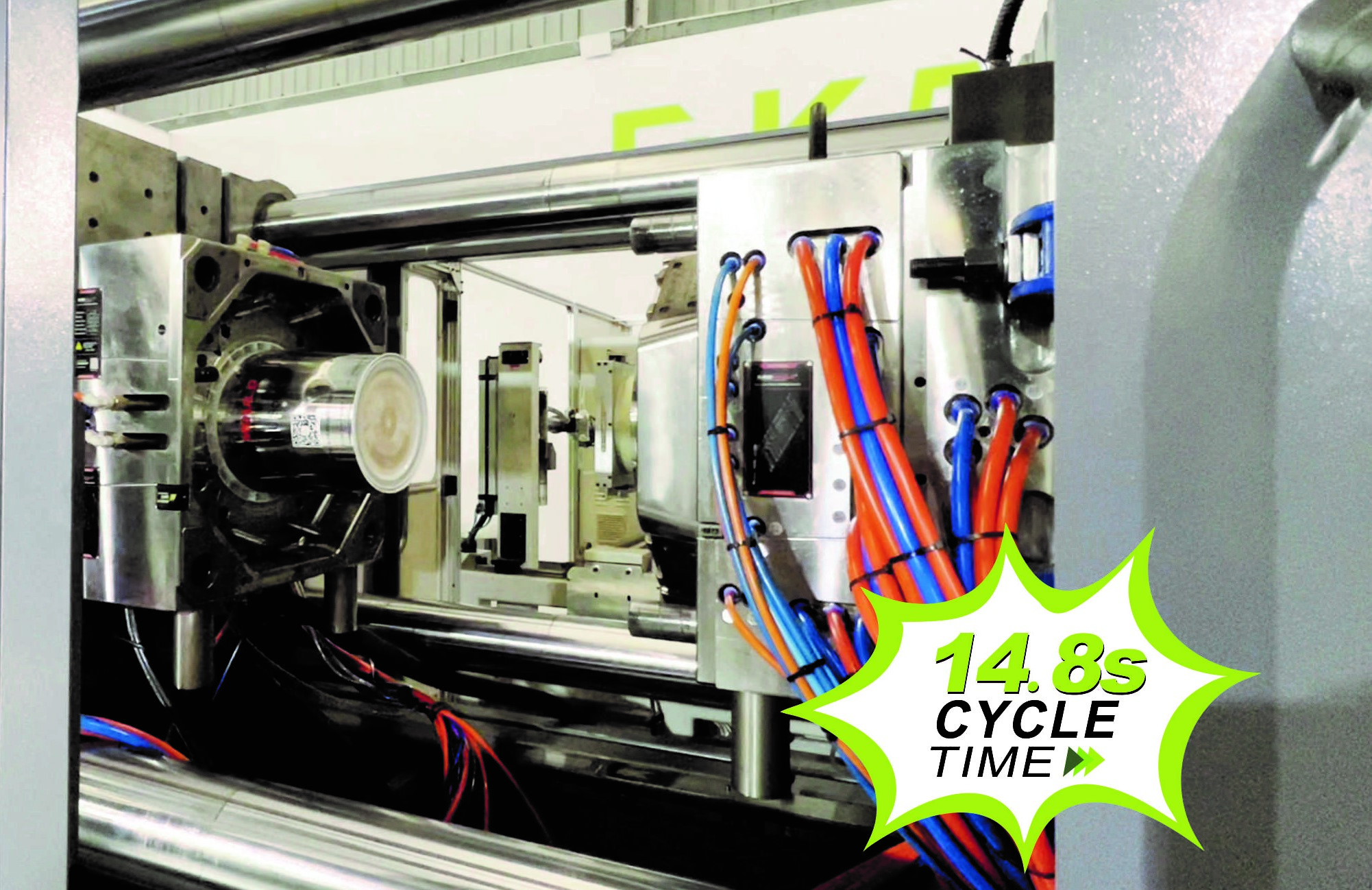

DKM PET Bottle Preform Production Line: Elevating Efficiency with DKM Injection Molds & Automated Systems

In the fast-paced packaging industry, the ability to balance speed, customization, and reliability defines market competitiveness. The DKM PET Bottle Preform Production Line—equipped with high-precision injection molds and automated processing modules—emerges as a game-changer, delivering scalable, high-throughput manufacturing for PET preforms (the foundational components of plastic bottles). By integrating advanced cooling technology, flexible cavity configurations, and rapid delivery, this system addresses the core demands of beverage, food, and cosmetic packaging producers

Core Technical Advantages of the DKM Production Line

The DKM system stands out for its engineered efficiency and adaptability, driven by four key features:

· Mold-External Cooling: Dual-station robots enable parallel cooling and production workflows, doubling operational efficiency by eliminating downtime between cycles.

· High Customization: Supports 8–144 cavity configurations, enabling producers to switch seamlessly between small-batch prototypes and large-scale mass production without requiring major equipment overhauls.

· Stable Fast Cycles: Achieves a 10–12 second production cycle (standard for 12g preforms), ensuring consistent output even during peak demand.

· 14-Day Fast Delivery: Streamlined manufacturing and supply chains let businesses deploy the line in weeks, not months—critical for seizing time-sensitive market opportunities.

Practical Applications & Industry Impact

This production line caters to the packaging sector’s diverse needs:

- Beverage Packaging: Produces preforms for water, soda, and juice bottles, with cavity counts scaled to match regional consumption volumes.

- Food & Cosmetics: Creates specialized preforms (e.g., small containers for creams, wide-mouth jars) via customizable mold designs.

- Sustainability Alignment: By optimizing cycle times and reducing material waste (via precise injection molding), the line supports brands’ eco-friendly packaging goals.

Why Choose the DKM Production Line?

For packaging manufacturers, this system solves two persistent pain points:

- Scalability: No need to invest in separate lines for small vs. large runs—adjust cavity counts to match order sizes.

- Speed-to-Market: Rapid delivery and fast cycles let businesses respond to trend shifts without delays.

In an industry where efficiency and flexibility are non-negotiable, the DKM PET Bottle Preform Production Line combines injection mold precision, automated workflows, and rapid deployment to redefine packaging manufacturing. To explore how this system can scale your production capacity, reach out to DKM via www.dkm.com or contact their team directly—turn lead times into market opportunities today.