Thin Wall Container Production Machine

As a fast consuming demand increase for the thin wall containers, thin wall container production machine also become hot project. Many customers purchase the whole production machine line for the new market developing. Thin wall container production machine include high speed injection molding machine, thin wall container mould, all necessary auxiliaries, such as autoloader, air-cooled water chiller, air compressor, etc.

With more than 15years production experience and upgrading, the molding line could run stable and high efficiency, with more power saving.

Thin wall container mould:

Multi-cavity solution with reasonable layout

High hardness and stable steel material

Valve gate hot runner system

Precision dimension control

Well-designed air venting system

Optimized cooling system

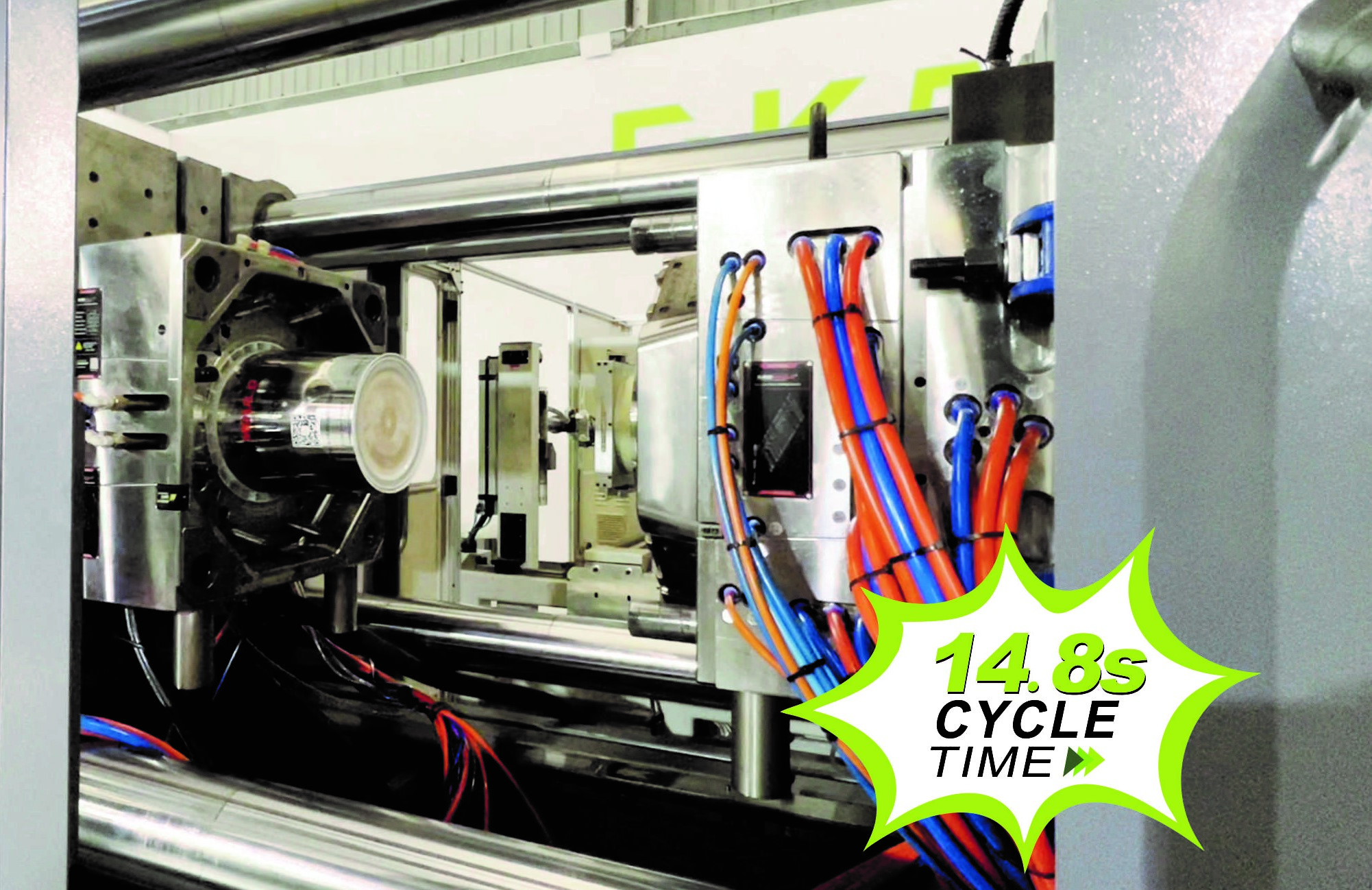

DKM High speed Injection Molding Machine DFS series:

More stable-Enlarged mechanical platen

More power saving-Servo motor system for raw material plasticizing

More balance moving-Single cylinder injection process

More precision control – Keba controller system

Whole package with high speed production

Automatic production auxiliary machines:

With collection robot, autoloading device and the chiller to make sure the whole production line fully automatic running.

A successful thin wall container production line required the mould and injection molding machine matching well with all auxiliary machines, to realize easy assembling, fast and stable running, with more power saving. Welcome to contact us for more information.