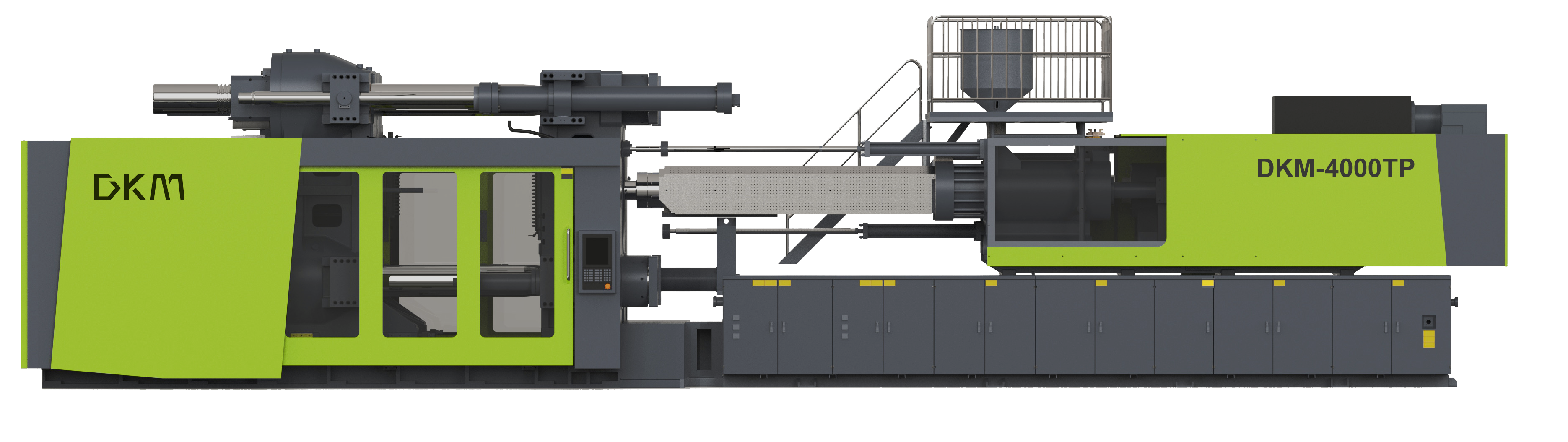

DKM-4000TP Large-scale Municipal Engineering Pipelines

Injection Molding Solution

Revolutionizing Urban Infrastructure

With the development of polymer materials, plastic pipes are gradually replacing traditional metal and concrete pipes,due to their light weight, corrosion resistance, and easy installation.

Modern polymer materials are transforming municipal engineering through:

Key Applications

◼ Drainage systems (DN1000+ pipes)

◼ Gas distribution networks

◼ Agricultural irrigation channels

◼ Sponge city water management

◼ PE septic tanks (2-10m³ capacity)

Material Innovation

Parameter

Specification

Industry Standard

HDPE

Corrugated pipes

Enhanced ring stiffness (SN8-SN16)

PVC-O

Pressure pipelines

25% weight reduction vs metal

GF-PE

Structural tanks

50kJ/m² impact resistance

As PE (polyethylene) material becomes more prevalent, plastic septic tanks are replacing traditional brick – built and fiberglass ones, becoming important equipment for sewage treatment. PE plastic septic tanks are made through rotomolding or injection molding, with optimized structures (such as reinforced ribs) to meet high – strength and impact – resistance requirements. They are mainly used for rural sewage treatment, municipal works, and building – related facilities.

With the advancement of injection molding technology, especially the widespread use of high – clamping – force injection molding machines (such as the DKM-4000TP), large – scale production of extra – large plastic products (such as large garbage bins, septic tanks, and municipal pipelines) has been made possible, meeting the needs of municipal and environmental protection fields.

DKM-4000TP Technical Superiority

Core Technical Advantages

High Clamping Force for Extra - Large Molds

The 4000 – ton clamping force meets the projected area requirements of municipal pipelines (such as drainage pipes with a diameter of ≥0100mm) and PE septic tanks (with a capacity of several cubic meters). It ensures stable mold closure during high – pressure injection, preventing spillover and flash. Considering the good fluidity of PE material, high clamping force maintains uniform melt filling, ensuring product density and surface finish.

Support for Deep - Cavity and Complex Molds

The two – platen injection molding machine offers larger molding space for deep – cavity molds (such as integrated septic tank molds). The tie – rod spacing accommodates extra – large molds, reducing parting line shift risks. It also supports multiple core – pulling mechanisms and sequence control, meeting the forming requirements of complex structures like pipeline flange connections and septic tank partitions.

Efficient Production and Large - Scale Manufacturing

Compared to traditional three – platen machines, the two – platen clamping mechanism reduces floor space by 30%, ideal for space – limited factories. It simplifies mold installation and, with a servo – driven system, saves over 30% energy. It can produce over 200 extra – large plastic parts daily.

Material Adaptability and Performance Assurance

Considering PE’s high fluidity and shrinkage (1.5% – 3.6%), the machine optimizes holding pressure (60% – 80% of injection pressure) and mold cooling system, reducing deformation and internal stress. Adding glass fiber or recycled PE (+30%reclaimed materials) improves impact resistance (≥50kJ/m²) and corrosion resistance, cuts costs, and extends outdoor service life to over 20 years.

Municipal Engineering Pipelines Injection Molding Solution Image

Performance Metrics

Parameter

DKM-4000TP

Conventional Machines

Improvement

Cycle Time

240-300s

400-500s

40% Faster

Mold Life

600,000+ cycles

350,000 cycles

71% Longer

Energy Efficiency

22kW·h/cycle

34kW·h/cycle

35% Savings

Dimensional Stability

±0.15%

±0.35%

57% Tighter

Conclusion

The DKM-4000TP two – platen] injection molding machine, with high clamping stability, deep – cavity compatibility, and intelligent control, is key for extra – large municipal pipelines and PE septic tanks. Its technology balances efficiency and quality, advancing municipal projects towards large – scale and eco – friendly development. In the future, green materials and digital technology will further boost its competitiveness in large – scale injection molding.