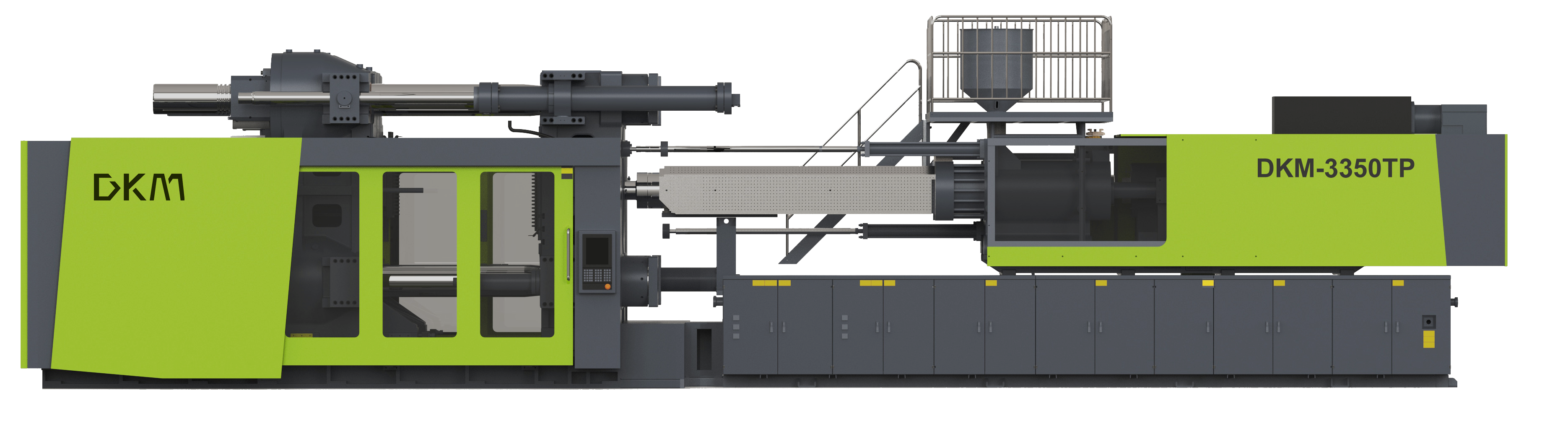

DKM-3350TP High-Capacity Trash Bin Injection Molding System

Plastic Bin Market Overview

Modern plastic waste containers excel in lightweight durability and environmental performance. Our engineered solutions cover:

Specialized Bin Types

◼ Wheeled containers ◼ Pedal-operated bins

◼ Multi-compartment sorting systems ◼ Industrial-grade stackables

Capacity Spectrum

| Capacity | Dimensions (L×W×H) | Clamping Force | Application |

|---|---|---|---|

| 1200L | 1430×1370×1080 | ≥3350T | Municipal/Industrial |

| 660L | 1230×1260×760 | 2350-3350T | Commercial Complexes |

| 240L | 1020×600×740 | 1150-2350T | Urban Recycling Stations |

| 120L | 940×460×550 | 850-1350T | Office Parks |

| 50L | 650×470×420 | 350-850T | Residential Complexes |

| 20L | 500×350×250 | 150-350T | Compact Spaces |

DKM-3350TP System Core Technical Advantages

High - Pressure Molding Capability

The 3350T clamping force meets the high – pressure injection needs of 1200L garbage bins. It ensures mold tightness during injection, preventing spillover and flash, and improving product density and surface finish. The split – mold design supports stable forming of deep – cavity structures, reducing deformation risks.

Large Molding Space

The two – platen injection machine offers larger molding space, fitting long stroke core pulling molds (e.g., for garbage bin flip – lids and reinforcement ribs). This reduces mold parting line shift issues and enhances forming accuracy.

Energy - Saving Performance

With servo motor drive, energy consumption is 30% lower than traditional hydraulic machines, nearly zero in cooling stage, aligning with green manufacturing trends.

Automation and Intelligence

It has automatic handling robots for unmanned assembly line operation, with a yield of over 98%. IoT enables real – time monitoring of clamping force and mold temperature. AI algorithms optimize process parameters, reducing debugging time and defect rate.

Advanced Mold Design

The mold’s combination of fixed, moving, and middle plates, along with sliding plate and groove quick – ejection, shortens ejection time by 40%. The hot runner system improves material utilization by 15%, lowering scrap cost.

Material Versatility

It supports HDPE, modified PP injection molding, and can add 20% glass fiber or nano – calcium carbonate to enhance impact resistance (≥50kJ/m²), ensuring bin usability between – 30℃ to 70℃. It can also blend 30% recycled plastic (e.g., recycled PP), reducing raw material cost and meeting environmental standards.

Performance Metrics

Parameter

Specification

Industry Standard

Capacity

Cycle Time

≤110s

150-180s

27% Faster

Mold Life

500,000+ shots

300,000 shots

66% Longer

Energy Use

18kW·h/cycle

26kW·h/cycle

31% Savings

Surface Finish

Ra0.6-0.8μm

Ra1.2-1.5μm

50% Smoother

Conclusion

The DKM-3350TP two – plate injection machine, with high clamping stability, energy – saving efficiency, automation and material adaptability, is key for large – scale 1200L bin production. Its advantages lie not only in efficiency and cost control, but also in promoting sustainable industry development through eco – friendly materials and smart processes. In the future, it can further integrate digital twin and bio – based materials for deeper green manufacturing transformation.