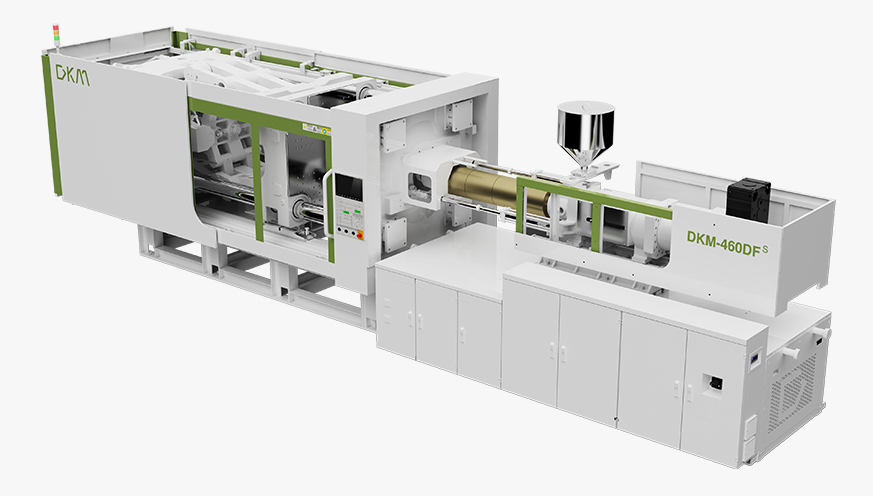

Thin-wall Injection Moulding Machine-The 6th Generation

With continued technical upgrades and improvements, DKM has launched the sixth generation of low-inertia thin-wall injection moulding machines. DFS series (200-800T), which is the upgraded iteration of DKM’s thin-wall injection moulding machines, with complete models available, combining the advantages of high speed, high precision, high efficiency and high energy saving, etc.

Clamping Force

2000KN-8000KN

Structure

toggle type (three-plate type)

Machine Drive

hydraulic servo system

As a leader in the industry

DKM has a deep understanding of market demand and has launched a highly efficient solution specifically for thin-wall food packaging production, a production line consisting of a DFS series injection molding machine with advanced IML (In-Mold Labeling) technology. This solution can not only greatly improve production efficiency, but also ensure the high quality standards of the final product.

- DKM DFS High Speed Thin-wall Injection Moulding Machine (200T - 800T)

The sixth generation of DKM low inertia thin-wall injection moulding machine—DFS series, is the achievement of DKM’s five years of research and innovation, which perfectly applies the low inertia high-precision injection moulding technology to improve the injection response speed and the accuracy of the injection position.

With continuous technological innovation and product upgrading, DKM applys both low inertia technology and QGL single cylinder design to DFS series, not only meets the customer’s high speed injection demand, but also reduces the cost of the machine as well as the energy consumption.

Clamping structure

The whole mould plate is strengthened, and the thickness of the middle mould plate is increased by 120% compared with the thickness of common one. Through stress analysis, DKM optimizes reinforcement layout for stronger mold clamping.

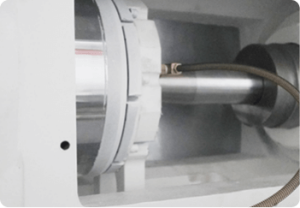

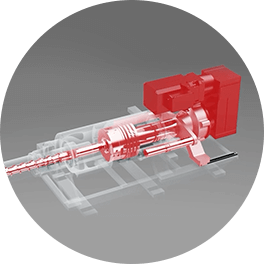

Injection station structure

Applying low inertia and high precision injection technology,DKM achives smaller injection inertia, and keep the injection repeatability valve within ±2‰ and make maximum injection speed is up to 800mm/s, which could greatly improve the repeatability accuracy of products.

Segmented frame design

The latest segmented machine frame design makes the machine gravity center lower and improves stability during production.

Single-cylinder injection system

Single-cylinder injection with high concentricity, hydraulic cylinder without oil return technology and no oil leakage in the injection process, it can effectively reduce the energy consumption of the injection moulding machine.

DKM can provide you with complete high-performance, high-efficiency and intelligent injection moulding equipment and customized services. DKM helps customers make molding more valuable with lower cost and higher efficiency.

- Application Cases

- Product Milk Tea Cup

- Machine DKM-360DFS

- Cycle Time 5.5s

- Cavities 8

- Product Yogurt Box

- Machine DKM-310DFS

- Cycle Time 5.8s

- Cavities 6

- Product Plastic Bowl

- Machine DKM-310DFS

- Cycle Time 5.5s

- Cavities 4

- Product Paint Pail

- Machine DKM-650DFS

- Cycle Time 18s

- Cavities 1

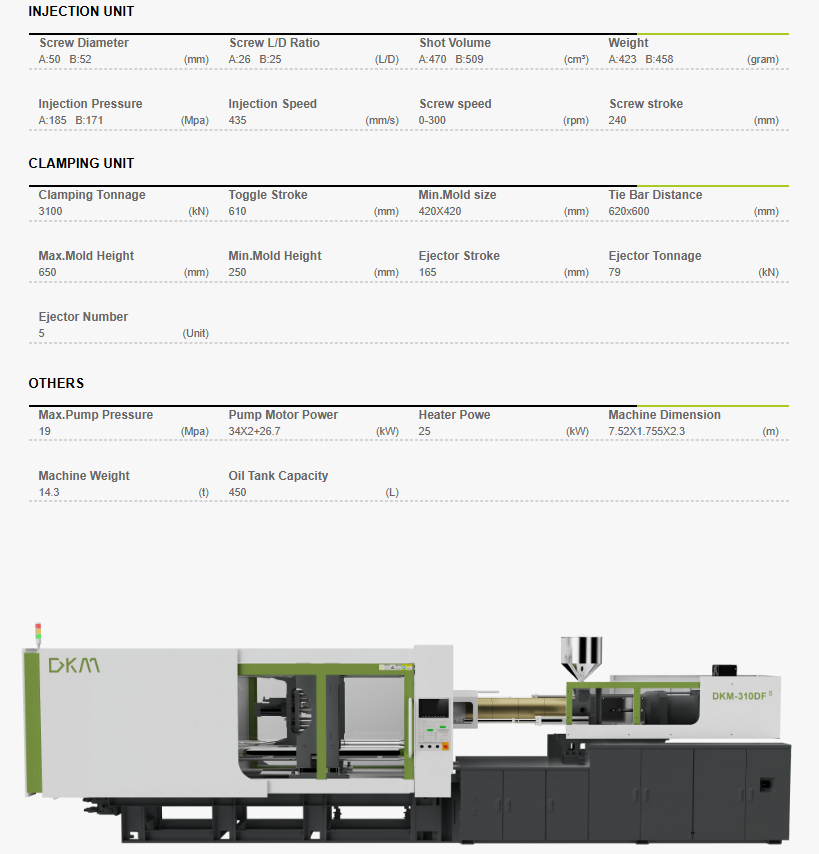

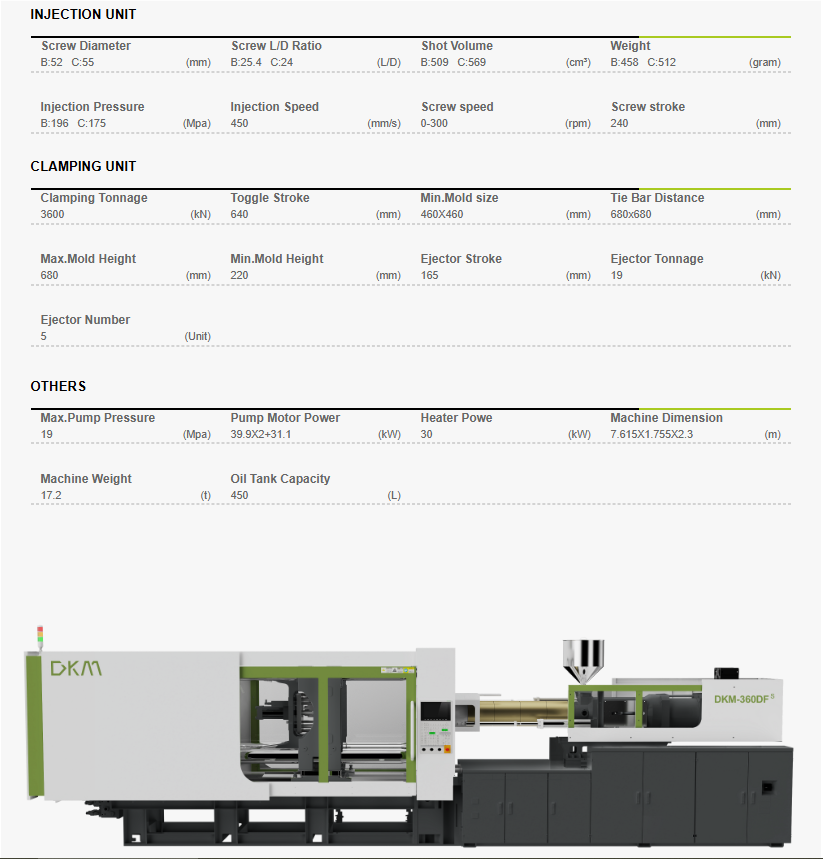

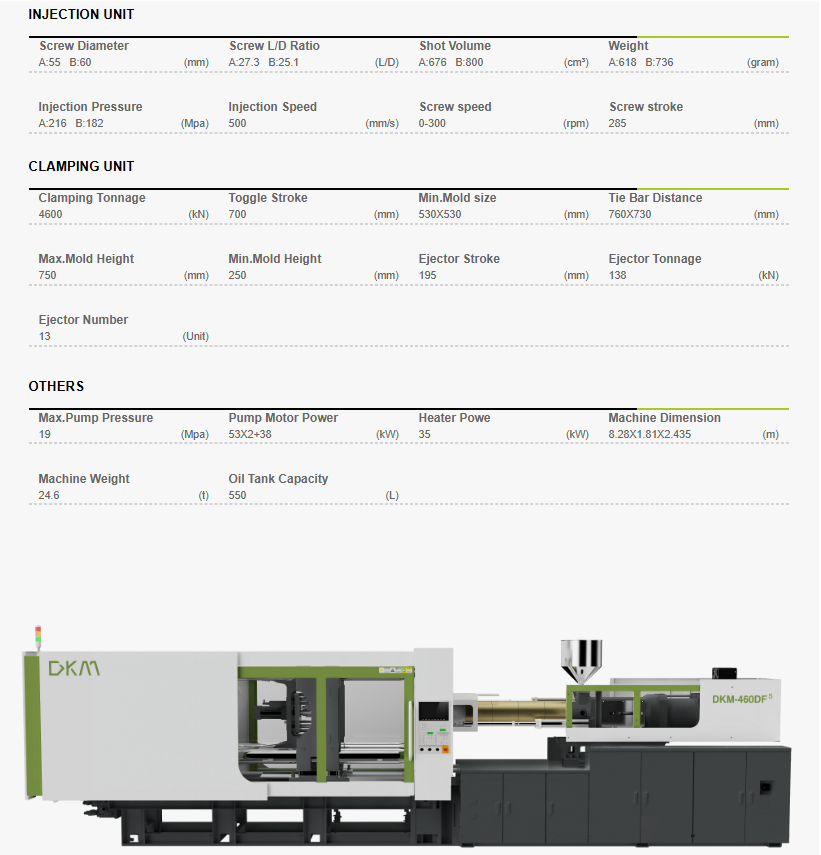

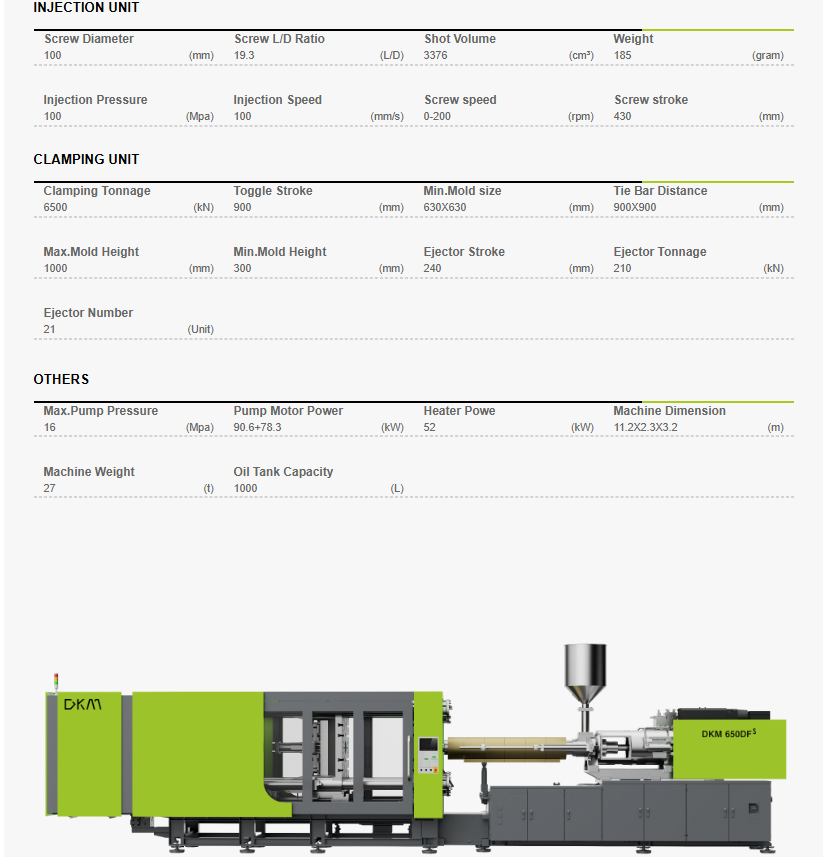

- Parameters of DFS High Speed Thin-wall Injection Moulding Machine

- Application Cases of DKM-460DFS Thin-wall Injection Moulding Machine

DKM-460DFS thin-wall high-speed injection moulding machine is used for the production of 8-cav milk tea cups, the production cycle is only 5.5s. It with the characteristics of high speed, high precision, high cleanliness and high energy saving. It is the best choice for the upgrading of high-speed machines.

- Advantages of DFS Low Inertia Single Cylinder High Speed Machine

The advantages of using a Servo Motor Injection Molding Machine (ranging from 80 tons to 4000 tons) are numerous and can significantly enhance your manufacturing operations. Here are the key advantages in detail:

Strengthen the centre top plate and reduce clamping stress.

• Semi-centre clamping, more uniform clamping force.

• Strengthen overall template, the thickness of the middle template is increased by 120%.

• Use more reasonable reinforcement layout, make the clamping stronger.

• The honeycomb structure of the hemisphere front template and the reduced centre hole design can withstand greater clamping force.

• Enlarge the column, increase the stress groove, and longer service life.

•Single cylinder injection, higher concentricity, longer screw assembly life.

•Independent hollow piston rod, avoiding storage material rotation and keeping longer piston sealing life.

•Low inertia patent application, separate the injection process and plasticization process. It ensures faster response speed and higher injection precision. It shall be more energy-saving with standard electric pre-molding technology.

The control system specially developed by DKM and Hongxun is running more smoothly.

Multi-axis linkage, with shorter production cycle.

It is equipped with 12 inch touch control screen as standard, which is more convenient to use.

Mould clamping is equipped with touchless electronic ruler as standard, which has higher precision and longer service life.

Double water drain design, more convenient to use.

Rear sheet metal independent opening and closing, maintenance is more convenient.

Reasonable lubrication layout, operation is more convenient.

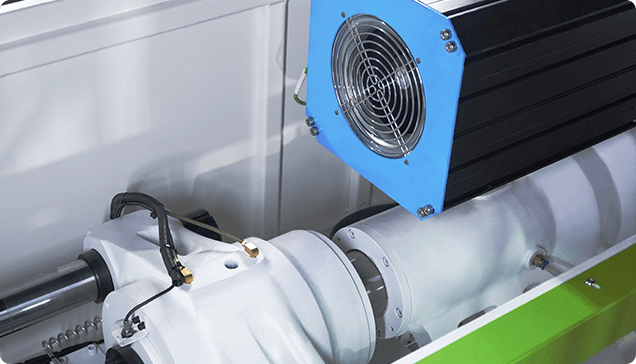

Using thermodynamic principles, scientific layout, and its electric box with better heat dissipation.

Independent external power supply, switch use more secure.

Infrared heating coil, which is safe and more energy-saving.

The DKM-DFS series is equipped with ready-to-use European standard connectors for manipulators, allowing users to easily automate production processes and improve efficiency.

The DKM-DFS series can be customised with thin-wall injection moulding machines according to users’ specific demands, providing them with a customised solution that suits their production needs. To help customer achieve maximum efficiency and productivity in their manufacturing

- Low Inertia Unique Cylinder Movement vs. Normal Single Cylinder

DKM One Stop Solution

Hydraulic oil internal circulation technology

DKM-460 high-speed machine adopts low inertia special principle, i.e. hydraulic oil internal circulation technology. By installing a special valve in the injection cylinder, the hydraulic oil does not have to be circulated through external pipelines, thus reducing energy loss. This technology is also a major technological breakthrough in the field of hydraulic injection moulding machines.

- Difference between low inertia special action and normal single cylinder

For Cost

The traditional single-cylinder structure is complicated, and the parts are more difficult to produce, which leads to the high cost of traditional single-cylinder injection moulding machines.

Low inertia single-cylinder injection moulding machine, with an independent hollow piston rod, greatly simplifies the single-cylinder structure, parts manufacturing is easier, and greatly reduces the machine cost.

For Injection Precision

The traditional single-cylinder injection moulding machine has a large weight for the injection station part, and its movement during the injection process, which will lead to the reduction of the repeatability accuracy of the injection products.

Low inertia single-cylinder injection moulding machine is equipped with a low inertia structure, which reduces the weight of the injection station part so that the inertia of whole injection station is greatly reduced. It effectively improves the repeatability of the injection action.

For Customer Use

The injection station part of traditional single-cylinder injection moulding machine adopts ejection cylinder screw sealing. It with the technical issues in the processing, assembly and hydraulic sealing parts. To solve the machine oil leakage problem, manufacturers usually increase the multi-layer sealing ring in the cylinder piston, but the design still leads to the ejection cylinder oil leakage.

Low inertia single-cylinder injection moulding machine breaks through the traditional classic structural defects. Its send back and injection separation. It achive send back and injection at one time by a piston. So the injection piston only reciprocating motion rather than spiral reciprocating motion, reducing the injection cylinder surface contact, greatly reducing the risk of oil leakage of the machine, and greatly improve the cleanliness of the machine, to achieve a higher rate of good-quality products.

For Energy Saving

New technology ensures the hydraulic cylinder without oil return, which saves the energy consumed by the hydraulic oil pump in the process of hydraulic oil circulation, and can effectively reduce the energy consumption of the injection moulding machine.

The reasons to choose DKM DFS series high-speed machine

If you are considering purchasing a DKM-DFS series thin-wall injection moulding machine, DKM offers the following advantages:

Rich injection moulding experience and industry knowledge

With more than 15 years of experience in the production of injection moulding machines, DKM can provide users with high-quality, reliable and intelligent injection moulding equipment. The company has a team of experienced engineers and technicians, who can provide you with perfect pre-sales, in-sales and after-sales services during the whole process of your production.

Versatility and Customisation Options

A wide range of customisation options to meet users’ unique production requirements for flexible production and a flexible clamping mechanism. DKM provides various injection molding solutions for different plastic parts.

High quality and high performance

The DFS series of high-speed machines can be used in a wide range of applications for the production of plastic products. DKM uses high-quality components and advanced technology to ensure stable and smooth machine operation.

Service & Support

DKM Injection Moulding Machines provides comprehensive service and support to our customers, including installation, training, maintenance and repair services. We have several service centers around the world to facilitate on-site help and support for domestic and international users.

Competitive Pricing

DKM offers competitive pricing for the DKM-DH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

Provide Complete Supporting Equipment and Service for Your Injection Molding Machine

DKM One Stop Solution

24Hours Services

Training Equipment Maintenance And System Upgrade

- Conclusion:

In short, the sixth generation of DFS low inertia thin-wall injection moulding machine is the upgraded iteration of DKM high-speed machine. It is the world’s first low inertia technology combined with electric pre-molding technology, single-cylinder technology, as well as special cylinder action technology. It truly saves energy with higher productivity and achieves the injection without oil leakage.