DKM is a brand of the Sino Group. With the brand mission of enabling users to create greater value, DKM, equipped with a global perspective and vision, continuously innovates in technology and service and has become a leading player in the global plastic injection molding equipment industry.

Company Culture

COMPANY MISSION

Offer Top Quality Solutions &.Equipments for Plastic Molding Industry:

Deliver 5H Molding technology and mentality which are high quality, high speed, high energy saving, high safety, high stability for plastic injection molding industry.

COMPANY VISION

Being the world famous supplier for Turnkey injection molding line with service,technology solution and equipment.

COMPANY RESPONSIBILITY

Quality Honesty Responsibility

Achieve customer value

Contribution to Society

QUALITY PRINCIPLES

With spirit of the craftsman, we are making efforts to produce reliable products for the clients through doing well in every detail, bettering the procedure, improving the process, and pursuing high quality.

Company Honors

2024

DKM established an Italian subsidiary, specifically responsible for the further development of all-electric machines and the sales and service of the company's full range of injection molding machines in the European market. The first all-electric machine of DKM was launched.

2023

DKM jointly released the low-inertia injection molding technology results with the relevant research centers of the National Engineering Academy and the National Plastic Machinery Association. The sixth-generation low-inertia high-speed injection molding machine of Dekuma was officially launched

2022

The first unmanned intelligent medical injection molding factory project was successfully constructed, opening a new chapter for the intelligentization of medical injection molding. The DKM medical injection molding dedicated machine MX series was included in the national first set of scientific research achievements.

2021

The company successfully undertook the construction of the National Engineering Research Sub-Center for Polymer New Molding Equipment of the Chinese Academy of Engineering after passing the review by polymer molding experts from the National Engineering Academy.

2020

the company initiated and undertook the construction of the Hangzhou Intelligent Manufacturing R&D Center to layout the technical provision of intelligent manufacturing solutions.

2017-2019

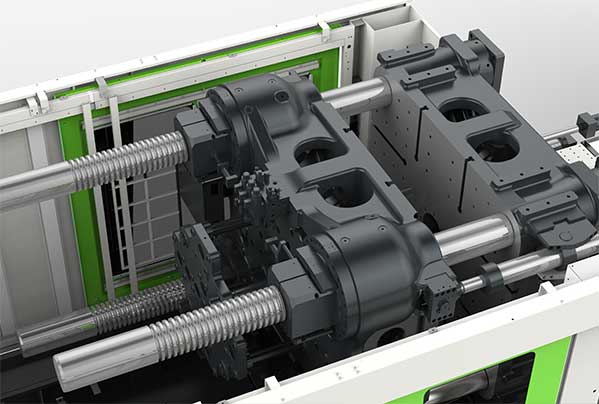

an Italian high-end R&D team was introduced, and the development and full-scale production of European two-plate machines ranging from 600 tons to 4,000 tons were smoothly realized. The Munich R&D Center in Germany was established to carry out the development of all-electric control systems.

2015-2016

the development and full-scale production of electro-hydraulic hybrid high-speed machines (200 tons to 600 tons) were successfully completed, making DKM the only brand enterprise in the world with a complete range of electro-hydraulic hybrid high-speed machine models.

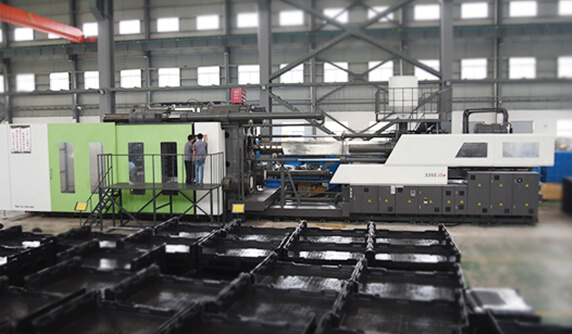

2008-2015

through eight years of continuous R&D investment, the company finally completed the development of large-tonnage injection molding machines of 2,800 tons and 3,350 tons and achieved full-scale production.

2007

DKM was established.

R&D Capabilities

INJECTION MOULDING MACHINES RND

Sino Holdings Group annually put much HR onto the injection moulding machine researching and developing. We have got many patents which are protected in many countries and have its own intellectual property rights on the injection moulding machine. We are always keening on HMI improving, high speed injection moulding researching, precision plastic filling with stable PC controlling.

01

Dakumar injection moulding machine RND team which is with more than 36 engineers, theyare professional in PC programing, electronic controlling system, mechanical system designand analyse.hydraulic system innovator. They came to DAKUMAR from Europe and ChinaMainland

02

During the past several years, based on the experiences and researching, Dakumar has got alot of achievements. Injection moulding machine security system for human protecting.Precision Plastify and Injection systems which are especially designed for light guidingcomponents. Injection moulding machine energy saving system with servo motor for plasticizing.-Injection moulding machine rotor clamping plate servo controlling with cooling water sealingsystem. PVC injection moulding machine special TC system. PET injection moulding machine special screw and barrel design. Robot design for side feeding and picking IML system.

03

Sino Holdings Group is continues on researching and developing for different types of newtechnologies and innovations for injection moulding machine. We are keening on offering thetop quality machines and services to plastic moulding industries

Philosophy

Dakumar is specialized in injection molding machine structure optimization, performance testing and improvement. Unlike conventional machine structure design and concept, we want to develop high speed injection machine in true sense, with multi-loop function and stable performance, adopting a brand new and unique design in China. And then we have our DKM5H series high speed injection machine

HIGH SPEED

HIGH PRECISION

HIGH ENERGY SAVING

HIGH SAFETY

HIGH RECYCLABILITY

which have stable performance with around 3s cycle time with high efficiency, different like traditional “fast” injection machine. And this is what differ Dakumar brand with other manufacturers.

RND Team

Dakumar has a team and joint venture with our European engineer and shareholders for injection molding machine researching and developing.

Achievements

·Injection moulding machine security system for human protecting. ·Precision Plastify and Injection systems which are especially designed for light guiding components. ·Injection moulding machine energy saving system with servo motor for plasticizing. ·Injection moulding machine rotor clamping plate servo controlling with cooling water sealing system. ·PVC injection moulding machine special TC system. ·PET injection moulding machine special screw and barrel design. ·Robot design for side feeding and picking IML system.