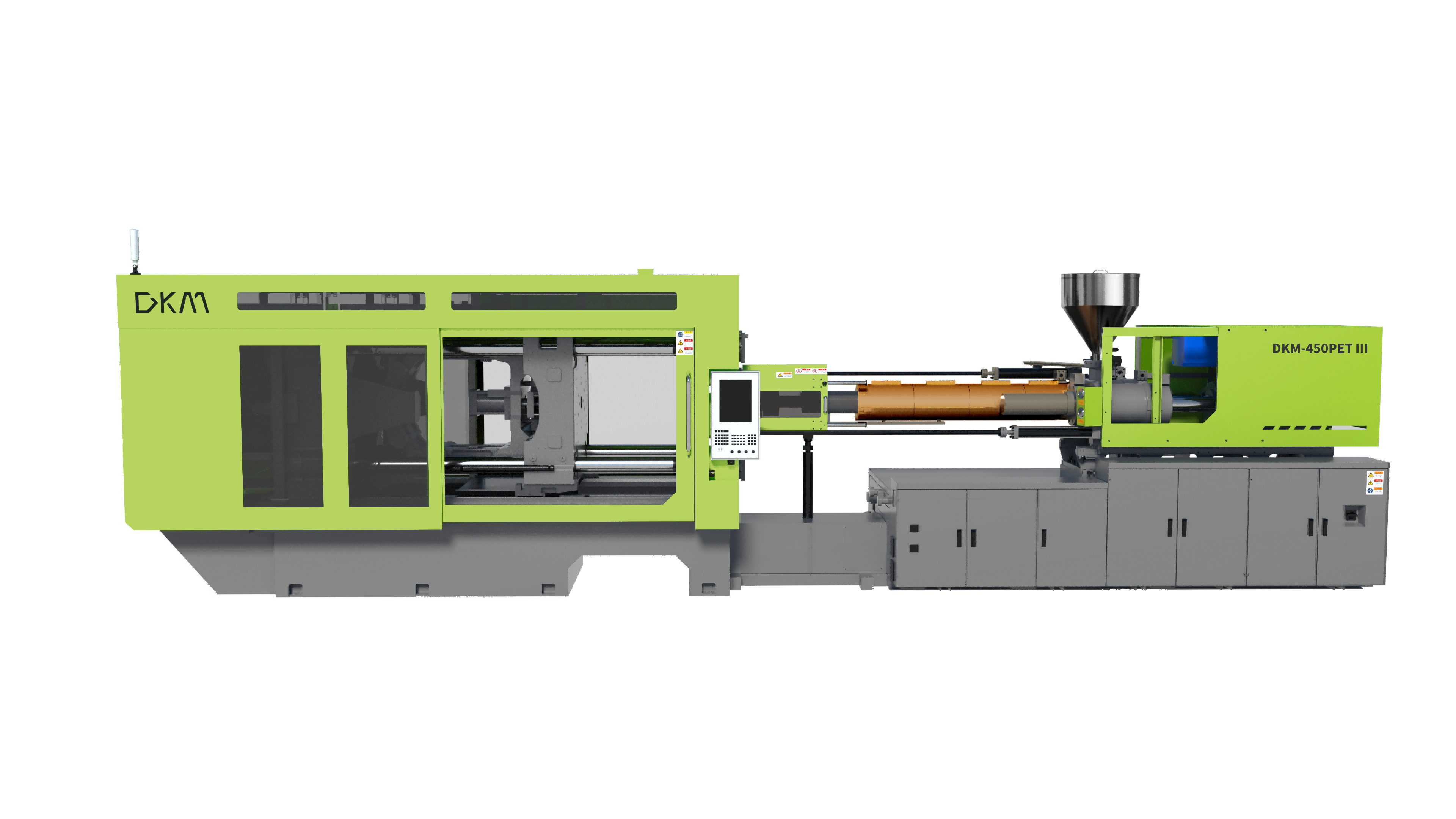

DKM Blood Collection Tube-Specific Injection Molding Machine

DKM blood collection tube-specific injection molding machine complies with high cleanroom standards and can be equipped with PET-specific screws. It accurately matches the plasticizing characteristics of PET materials, ensures high precision and cleanliness throughout the production process, stably produces high-quality medical blood collection tubes, and serves as an essential piece of equipment for the large-scale and standardized production of blood collection tubes.

4 Core Advantages of Choosing DKM Blood Collection Tube Injection Molding Machine

In a blood collection tube production line, injection molding is the primary and core process. The quality of injection-molded components such as tube bodies, caps and rubber stopper seats directly determines the quality of finished blood collection tubes. If defects occur in the injection molding stage, all subsequent processes will be rendered meaningless. Therefore, injection molding equipment must meet the following core requirements:

High Injection Repeatability

Medical PET blood collection tubes have stringent dimensional accuracy requirements. The equipment must precisely control the injection volume for each shot to eliminate under-filling or flash issues. Under-filling leads to incomplete product molding, while flash impairs the airtightness of blood collection tubes and endangers blood sample preservation. The DKM blood collection tube injection molding machine has an injection repeat accuracy tolerance of ≤ 0.5‰, fully meeting production standards.

High-Speed Injection

The equipment is equipped with high-speed injection capability, allowing molten PET to fill mold cavities quickly and evenly for synchronous cooling. This ensures uniform product shrinkage and stress distribution, effectively avoiding defects such as tube body sink marks and warping. Cavity filling time can be shortened to less than 1 second, significantly reducing injection and cooling durations and boosting production efficiency.

High-Speed Mold Opening/Closing + Precise Clamping Force

The high-speed mold opening and closing design shortens the molding cycle and directly improves production capacity. Meanwhile, the equipment can precisely control clamping force, preventing mold positioning inaccuracies caused by inertia from high-speed movements. It not only ensures stable product dimensions but also effectively extends the service life of high-precision blood collection tube molds.

High Cleanliness

Medical injection molding requires compliance with cleanroom requirements of Class 100,000 or higher, fully meeting the stringent cleanliness standards of modern medical production workshops and preventing contamination of blood collection tubes.