Core Equipment

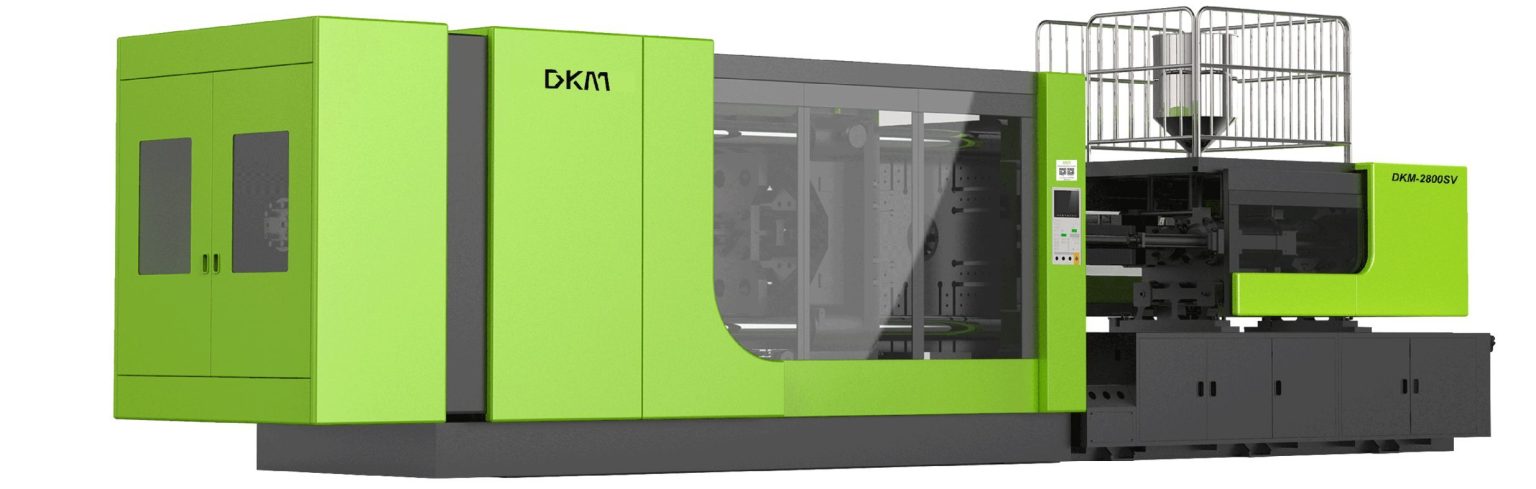

SV servo injection molding machine: equipped with advanced servo drive system to achieve precise speed and pressure control. In the production process of air-conditioning shell, it can quickly adjust the injection molding parameters according to the subtle changes of the mold to ensure the molding accuracy of every inch of the shell. Its efficient and stable operation greatly improves production efficiency, reduces energy consumption, and effectively controls your production costs.

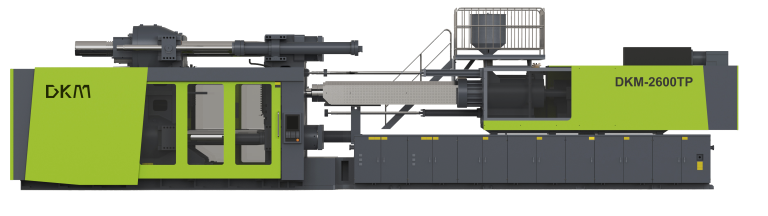

TP two-plate injection molding machine: adopts a unique two-plate structure design to optimize the rigidity and stability of the machine. When injecting air-conditioning shells, it can withstand higher injection pressure to ensure the strength and durability of the shell. At the same time, it simplifies the mechanical structure of the machine, reduces failure points, reduces maintenance costs, and provides reliable protection for your production.

Air-conditioning shell mold

Mold development strength: As a well-known mold manufacturer in the industry, SINOMOULD Mold Company has a professional mold design team and exquisite manufacturing technology. They have a deep understanding of the special requirements for air-conditioning casings, and strive for perfection in every link, from the structural design of the mold to the layout of the cooling system and then to surface treatment, laying a solid foundation for injection molding high-quality air-conditioning casings.

WHY CHOOSE DKM?

less cost for communicating and time, get them at one time from only us.

strong uniformity, clear responsibility in whole project, quick delivery of all goods together.

Gant schedule for processes arrangement to ensure you get a quality air conditioner production line on time.

24hs on line.