Auxiliary Equipment

ACI Air-Cooled Water Chiller

Engineered specifically for the plastic manufacturing sector, this industrial chiller significantly enhances machinery efficiency and product quality, boosting profitability.

WCI Water-Cooled Water Chiller

The industrial chiller is specially designed on purpose to be used in the plastic manufacturing industry .This equipment can greatly raise the working efficiency of manufacturing machines and obviously improve the quality of products and thus,earn more profit.

Features:

01

The inside safety protection can guarantee the long lasting of the chiller well. The pump is used made in Taiwan and all parts of cooling system are imported from the USA. Mexico Denmark and Japan

02

Equipped with shell pipe condenser and stainless steel cased evaporator, which are quite easy to be cleaned and maintained.Equipped with automatic water supply device in ttie water- tank.

03

larger than model XC-20 are assernbled 2 sets or 4 sets of compressors,so they are able to used as separable or together to reduce the resource waste

04

Complete with safety protection and error indication system,including compressor over load, protection,pump over load protection, high pressure and low pressure protection and phase failure protection

05

Equipped with figue intellectualized temperature controls,which can accuratety measure and control water temperature within the range of 5°C-35°C

Applied Machinery

Cooling system of oil temperature.ultrasonic,high frequency machinery. Cooling system of injection molding machinery. cooling system of blow molding machinery. Cooling system of extruder.

Additional Equipment For Option

- Starter of timer switch.

- Large type of water filter.

- Protection switch for prove the electric leakage.

- Cooling tower and pump.

VACUUM AUTOLOADER

The main engine and the material hopper are designed separately, and thus it is safe, easy and convenient to be operated .The whole operation is controlled by Micro Trip computer Equipped with an independent filter, which is very convenient to clean up dust. The equipped muffler reduces the no isein operation STL-900GN-2 controlling two suction hopper by one single controller not only can avoid taking space but also manage convenient

The air revolving dust arrester reduce the clean times of filter, is suitable for the grinded material conveying

STL vacuum autoloader

2 CONTROLLING TWO SUCTION HOPPER BY ONE SINGLE CONTROLLER

Features:

1

Stainless steel material hopper is light in weight, durable and very convenient for cleaning the device.

2

The bunker with electronic eye can be installed on the charging inlet of molding machine directly

3

Can select two-material proporional valve, used for new material mixed grinded material using or instant receiving of grinded material

4

Auto-protective device protects motor against overioading

5

The control box, being designed separately, is easy to be well maintained

6

Auto-buzzer will give alarm while lacking material

Screw air compressor

Screw air compressors are high-efficiency and reliable gas compression devices that utilize the meshing movement of twin screw rotors to intake, compress, and discharge air. Key advantages include continuous air supply, low energy consumption, and easy maintenance, making them widely used in industrial manufacturing, mining, construction, and more.

DEHUMIDIFYING,DRYING AND FEEDING UNIT (THREE IN ONE)

SD dehunmidifying,drying and feeding unit equipped honey-comb dehumidifier. The moisture proof drying material tube adopt bottom blowing design with circling air exhausting device,prevent heat energy emitting keep temperature, improved dying effeiency .The dew-point monitor indicator for customer selection, which can monitor the dew-point.

Use two cooler in dehumidifying system,guarantee low temperature on air and dew-point.

- Compact in size for easy moving and the machine can be replace easily

- Airtight loop feeding system, prevent the dried raw material to be re-moisture by contact external air

- With built-in restrictive valve, guarantee no remained materal in pipe

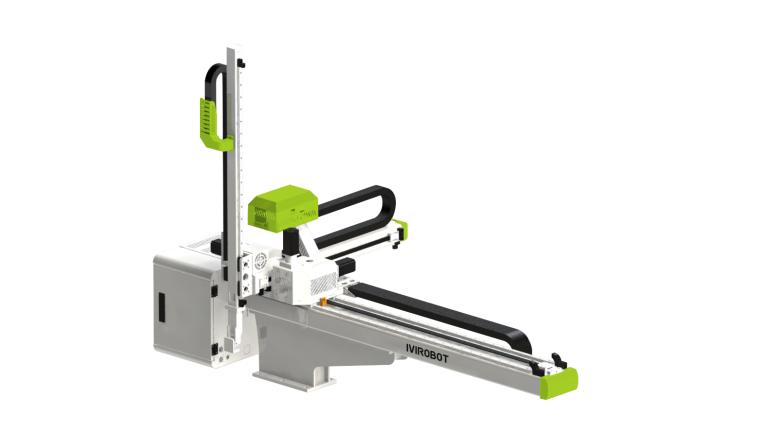

IVIROBOT

The leader of industrial intelligence

IVI is a leader in robot manufacturing, integrating research and development, manufacturing, after-sales service, and focusing on providing industrial intelligent manufacturing solutions.

IVI Three-axis Robot

In the tide of intelligent manufacturing, IVI Robot Co., Ltd., with its excellent research and development capabilities and profound technical accumulation, launched IVI three-axis robot, an automatic tool designed for modern industrial production lines. With its high precision, high efficiency and high reliability, IVI three-axis robot has shown strong application potential in electronics, semiconductor, food, medicine, automobile and other industries, and has become an ideal choice for enterprises to improve production efficiency, reduce costs and improve product quality!

IVI IML Robot

Our IML robot series covers a wide range of application scenarios from simple to complex, including but not limited to the automated labeling of products such as ice cream cups, yogurt cups, bubble tea cups, silicone sealant buckets, and paint buckets. Each robot is meticulously designed to ensure precise and stable labeling performance even in high-speed production environments.

IVI Five-axis robot

Features:

multi-degree-of-freedom design, flexible response to complex working conditions, suitable for precision processing and assembly.

Advantages:

highly flexible, strong scalability, and meet diverse production needs.

Visual inspection production line

The visual intelligent manufacturing production line launched by IVIROBOT Technology Co., Ltd. integrates machine vision, artificial intelligence, and automation control, providing a comprehensive intelligent upgrade solution for the manufacturing industry.