Beverage Crate Production Line

Engineered for Breweries & Bottlers

Specialized in providing high performance cases for beer, soda and beverage logistics, DKM’s production lines provide FDA-compliant leak-proof containers that can withstand harsh environments – from brewery chillers to bottling plant conveyors. The crate is designed for the liquid handling industry with faster filling, safer stacking, and lower breakage rates.

Our beer & cola crates are ideal for beverage distributors, warehouse operations, and retail chains. They excel in cold chain logistics, protecting beverages from temperature fluctuations while maintaining integrity during transportation. The durable design supports automated sorting systems in distribution centers and provides branding opportunities through customizable labeling options.

Beverage Industry Applications

- Beer Breweries: Nestable crates for bottle/can transport (up to 24 bottles/box).

- Soda Bottling: Acid-resistant crates for syrup and finished product handling.

- Dairy Drinks: Insulated designs for milk/juice cold chain logistics.

- Craft Beverages: Small-batch customizable crates (MOQ 5,000 units).

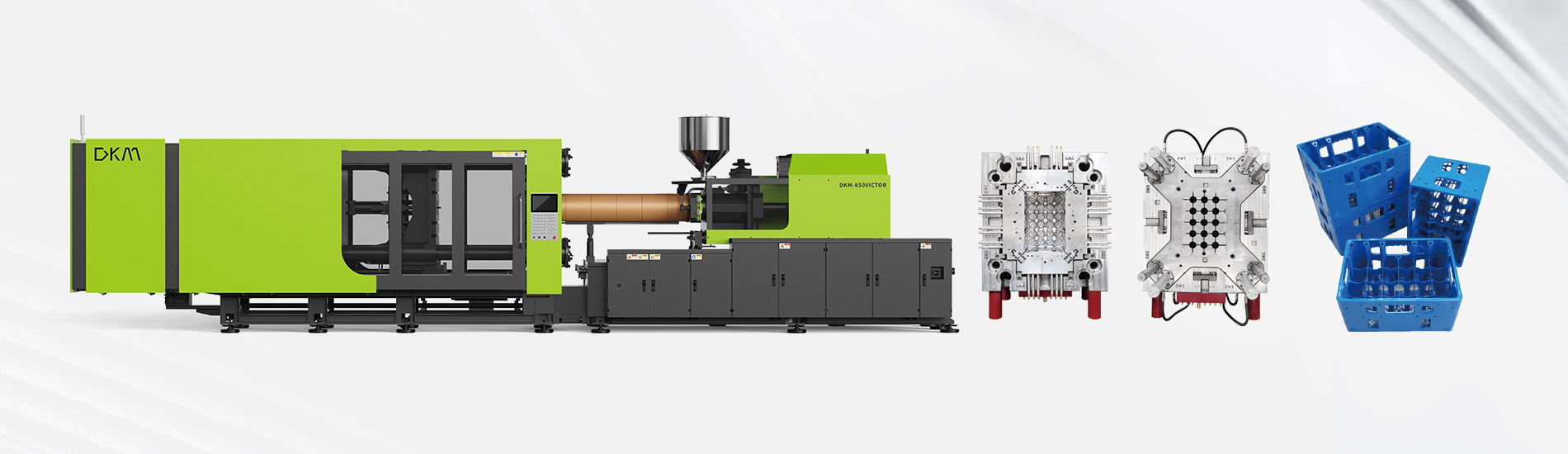

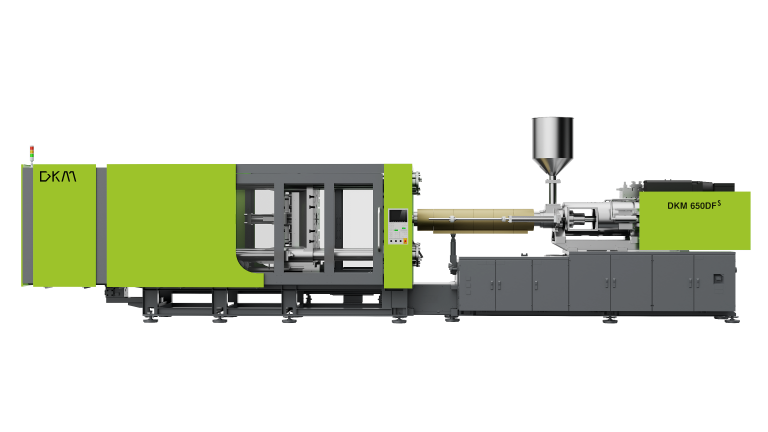

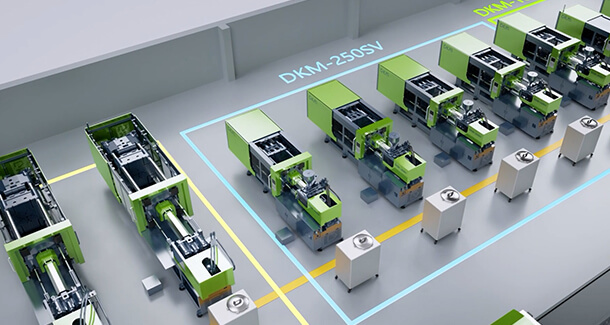

Beverage Crate Molding Machine

01

Efficient Production: Equipped with a high-speed injection system and optimized mold design, it improves production efficiency with a maximum injection speed of up to 800mm/s.

02

High-Precision Injection Molding: The low-inertia single-cylinder structure with an independent hollow piston rod ensures product dimensional accuracy and quality stability. The seal prevents oil leakage for a clean production environment, meeting high-end market requirements.

03

Energy-saving and Environmental Protection: Advanced energy-saving technology reduces consumption, with a standard electricity meter on the machine body for clear visibility of power savings (20%-30% per machine). This optimizes energy efficiency and lowers operating costs.

04

Easy Operation: An intuitive interface and intelligent control system allow operators to quickly master machine operation, improving work efficiency.

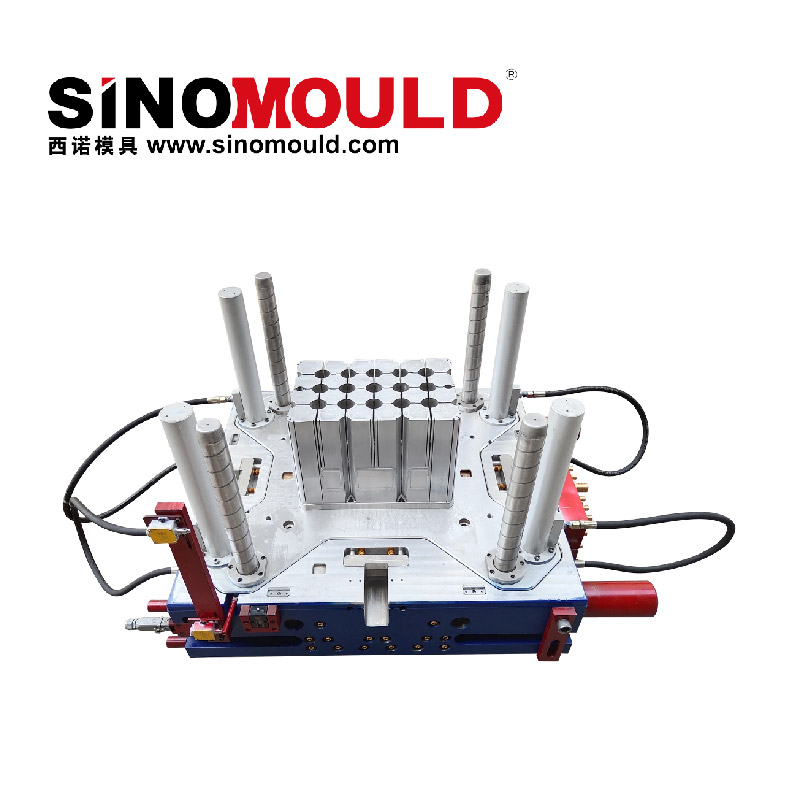

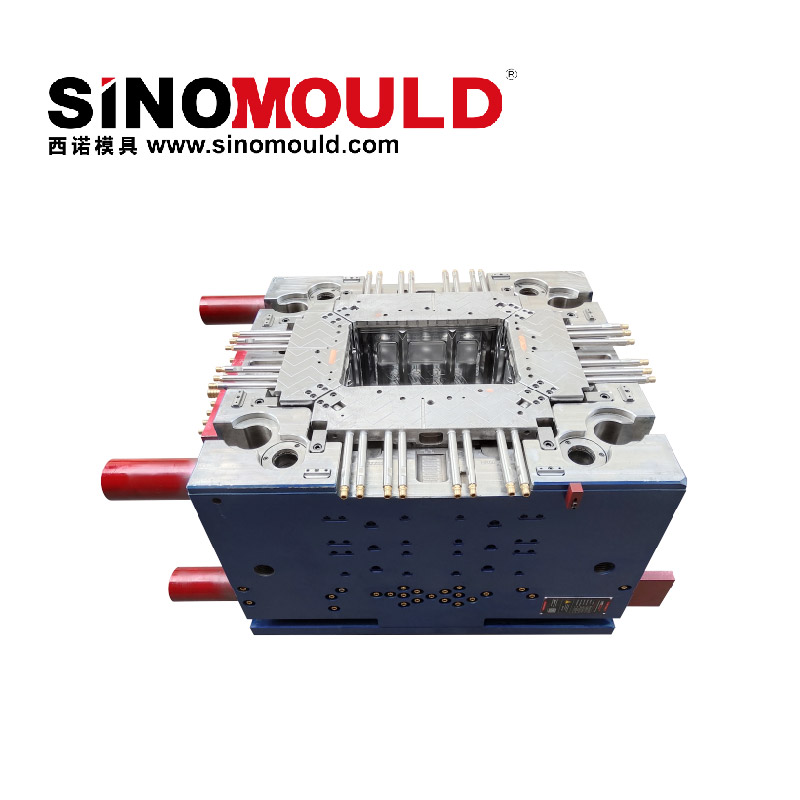

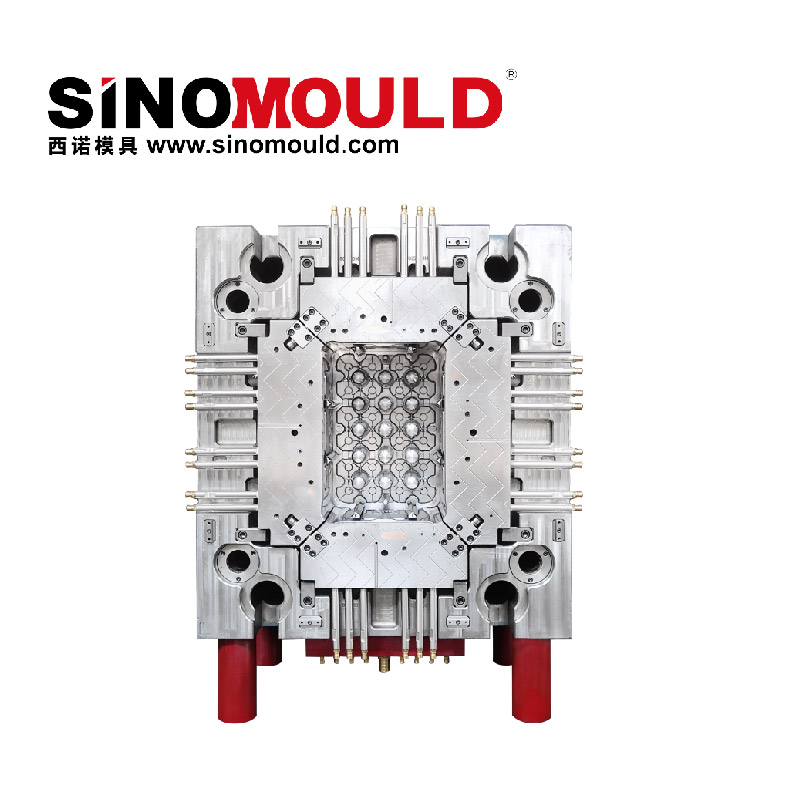

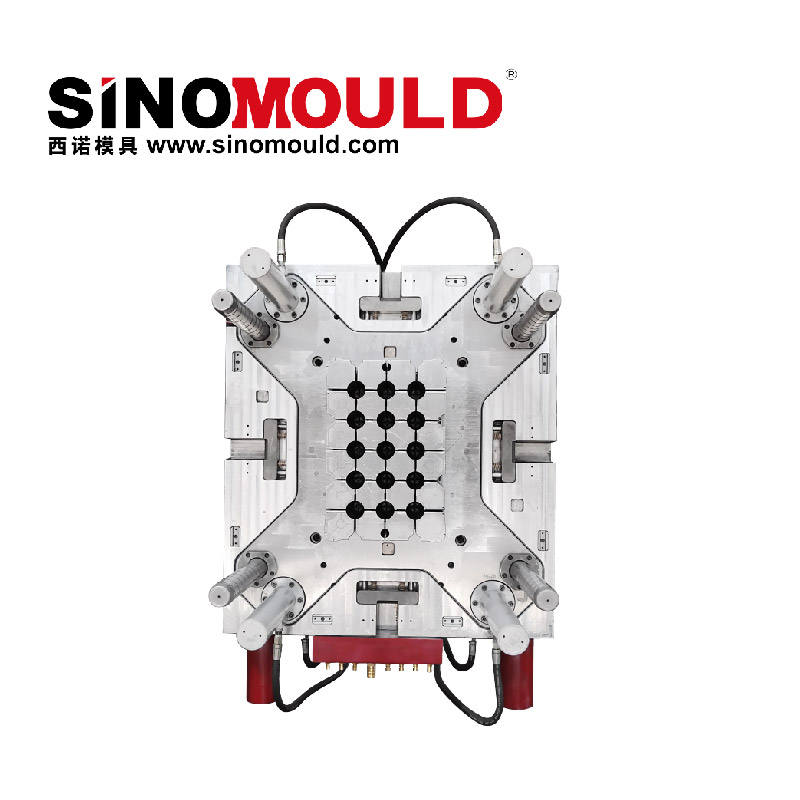

Crate mould

Product: bottle & cola crate

Mould Steel:DIN1.2344+cube

Cycle Time:20s

Mold Size:1260″770*770mm

Mold Feature:inserted with moldmax material,high efficiency ofcooling in each block,advanced structure for ejecting automatically.-fast cycle time,easy maintenance.Crates can be designed accord-ing to scholler size stacking and dimension standard,it is widelywelcomed by our high quality level customers.

DKM Crate Highlights

Smooth PP/PE material resists sugar/acid buildup, CIP washable for food-grade cleanliness.

Interlocking ribs and textured bases prevent toppling even when wet (+20% stability vs. Standard crates).

Multiple service centers worldwide for timely professional support.

We commit to swift production and delivery, enabling prompt customer production.

Our engineers install, commission equipment, and provide training for smooth customer start-up.

For more information about DKM’s beer & cola crates production line or to schedule a demonstration, please contact our beverage industry specialists.