Milk Cap Production Line

Precision Engineering for Dairy Packaging Excellence

Elevate your dairy packaging with DKM’s state-of-the-art Milk Cap Production Line, designed to deliver unmatched speed, hygiene, and reliability. From fresh milk to yogurt and specialty beverages, our line ensures airtight seals, food-grade compliance, and seamless integration with your filling systems.

Why Choose DKM’s Milk Cap Line?

01

High-Speed Efficiency: Achieve outputs of 8,000 caps par heure with servo-driven automation, optimized for dairy industry demands.

02

Food-Safe Materials: Compatible with PP, HDPE, and biodegradable plastics, meeting FDA and EU food contact standards.

03

Leakproof Sealing Technology: Advanced compression molding and torque calibration ensure 100% airtight closures, critical for liquid dairy products.

04

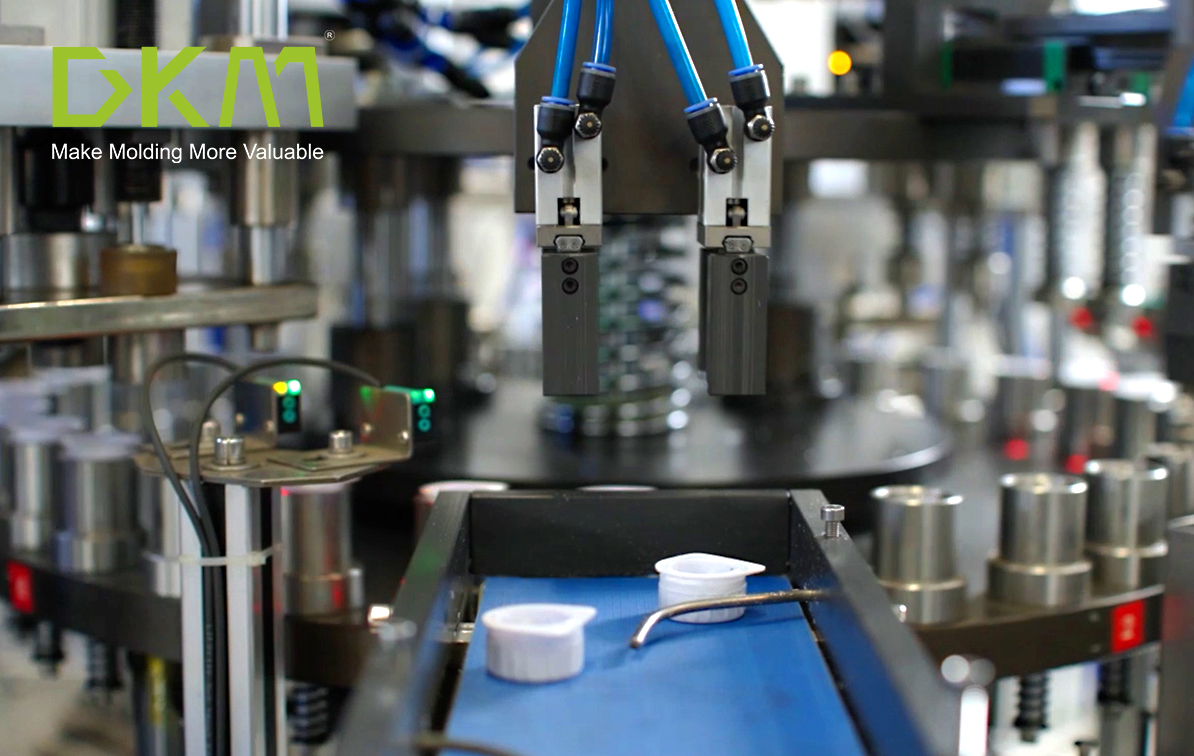

Smart Quality Control: AI vision systems detect defects in real time, ensuring caps meet dimensional and surface quality benchmarks.

05

Energy Optimization: Reduce power consumption 20%-30% while maintaining peak performance.

Milk Cap Production Equipment

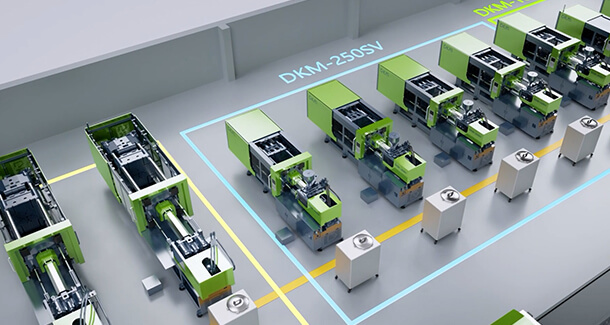

DKM The injection molding machine used in the milk cap production line is our DKM-350SV injection molding machine. Servo moter injection molding machine can meet various production needs, is the best choice for factory manufacturers.

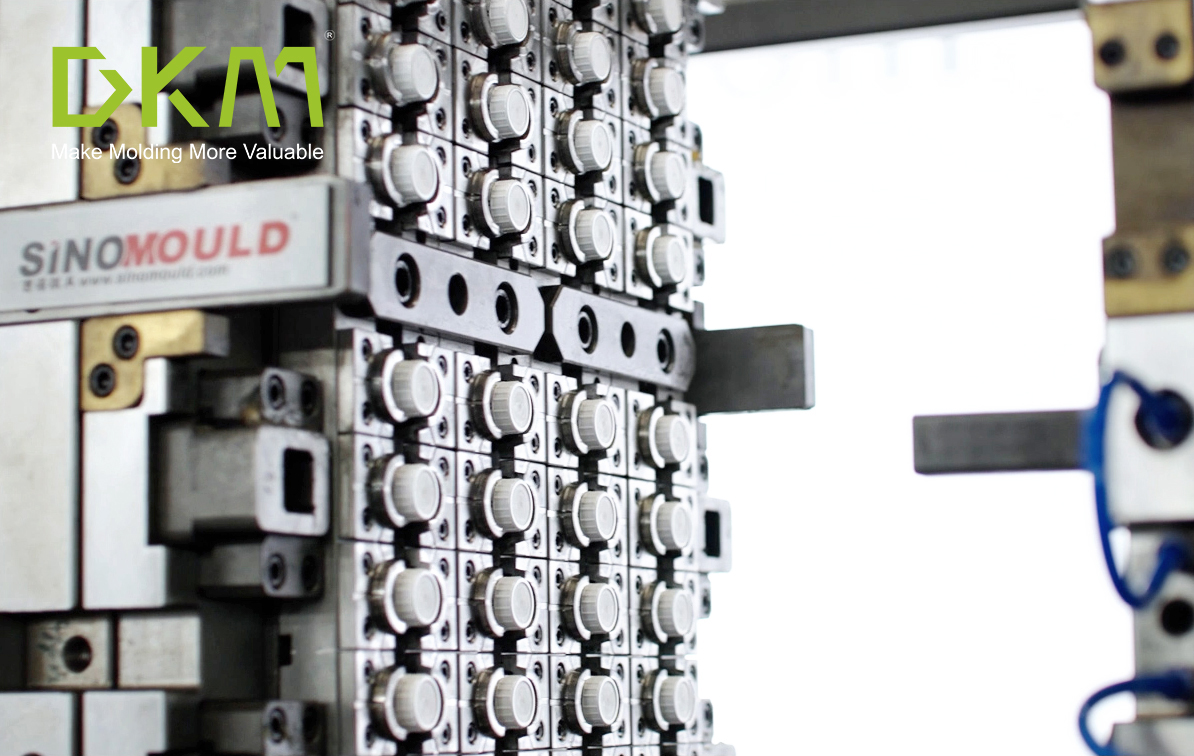

DKM the milk cap production line has chosen SINOMOULD’s milk cap molds. Built with quality steels for long-term, stable production, reducing maintenance needs and total cost of ownership.

When every cap must seal perfectly, inspection becomes critical. Our DKM Milk Cap Production Line features dedicated auxiliary equipment, including advanced plastic cap inspection units, engineered to guarantee 100% product integrity and packaging safety.

Core Components & Innovations

- Precision Molding Unit: Multi-cavity molds with rapid cooling for consistent cap geometry and reduced cycle times.

- Material Handling System: Automated drying and conveying of raw materials to prevent contamination.

- Torque Calibration Module: Ensures caps meet precise sealing force requirements for liquid retention.

- IoT-Driven Analytics: Monitor production metrics (e.g., defect rates, energy use) via cloud-based dashboards for proactive maintenance.

Applications

Fresh Milk & Cream: Tamper-evident screw caps with freshness indicators.

UHT Packaging: Aseptic caps for long-shelf-life products.

Plant-Based Beverages: Customizable designs for oat milk, almond milk, etc.

Custom Solutions & Support

Leverage our CAD integration (supports AutoCAD R14–2024 formats) to prototype caps with unique logos, ergonomic grips, or smart features (e.g., QR codes).

Certifications include ISO 9001, HACCP, and NSF/ANSI standards.

From installation by certified engineers to operator training and 24/7 technical support.