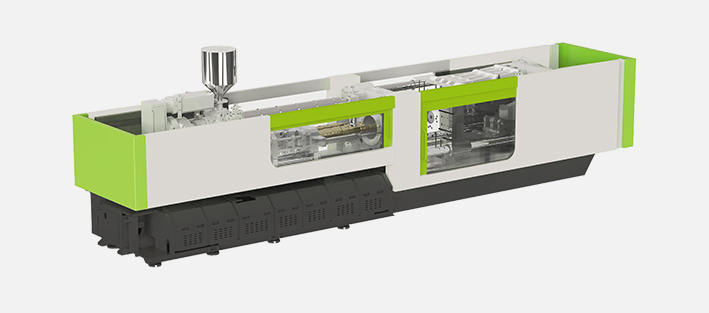

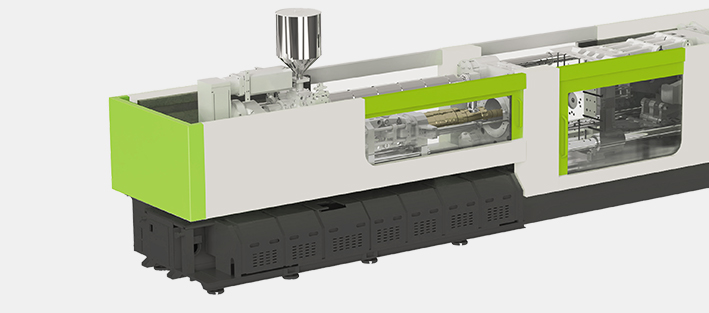

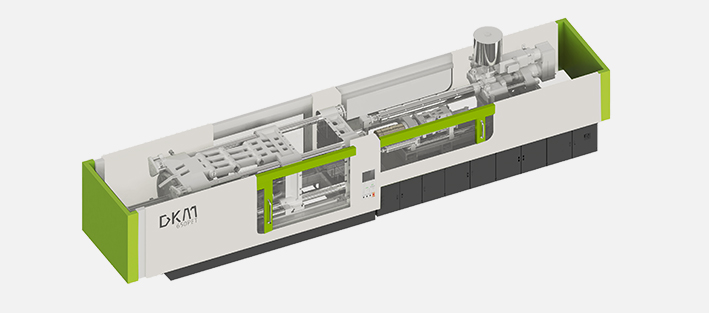

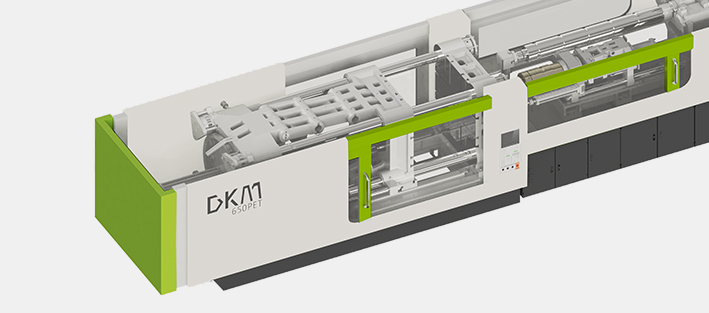

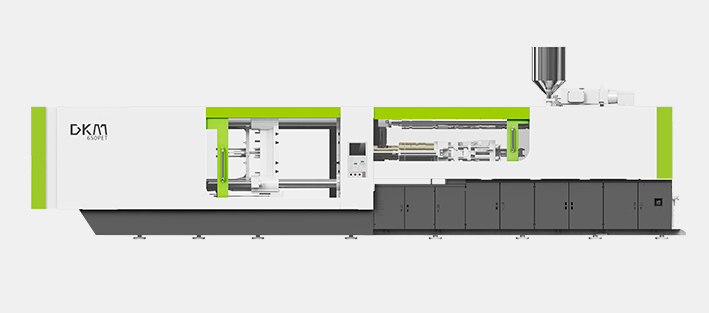

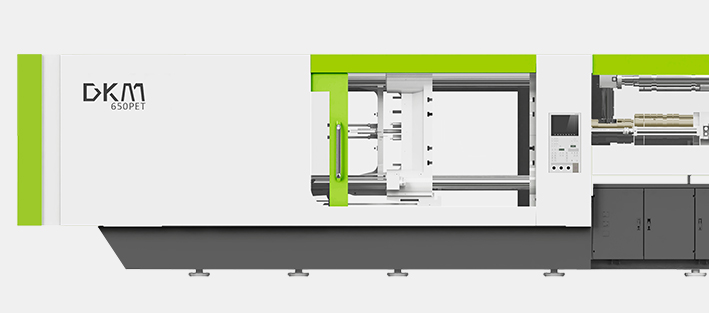

PET Injection Molding Machine (250Ton - 650Ton)

DKM has around 20 years of experience in PET injection molding machines. Since DKM establishment, DKM’s PET injection molding machines have been updated and iterated to the 3rd generation. DKM-PET III has the features:Rapid plastic melting, rapid mixing, high-speed injection, high-precision injection.Among the different demand of plastic injection molding products, PET injection moulding machines have distinguished themselves as crucial tools for creating high-quality plastic components. Due to their remarkable performance, accuracy, and versatility, these machines—whose sizes range from 250-650Ton —are highly recognized across a variety of industries of liquid packaging and household parts.

Clamping Force

2500-6500kN

Structure

Toggle(Three-Platen)

Machine Drive

Hydraulic Servo System

- PET Injection Molding Machine, 250-650 ton

Modern production technologies are driving the transformational phase that the plastics sector is currently going through. The machine for PET injection molding is one such innovation. With tonnage capabilities ranging from 250 tonnes to 650 tonnes, these innovative machines set the bar for innovation and enable producers to create high-quality plastic components with extraordinary accuracy and efficacy. PET injection molding machines are becoming essential tools for many industries thanks to their exceptional capabilities and wide range of uses.

PET injection molding machine is designed for the characteristics of PET materials, suitable for all kinds of plastic products using PET as raw materials, including but not limited to PET bottles, PET storage boxes, etc.

DKM PET injection molding machine in addition to the injection performance of the upgrade, but also pay attention to the human design of the machine.

It features user-friendly interfaces with intuitive control panels and touchscreens, enhancing usability and productivity. The machines are robustly constructed with durable materials and components, ensuring longevity, reliability, and consistent performance even under heavy production loads.

Furthermore, safety measures such as emergency stop buttons, safety interlocks, and protective barriers are incorporated, providing a secure working environment for operators.

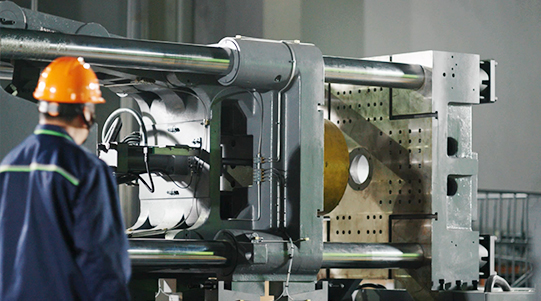

- PET Injection Molding Machine (250Ton - 650Ton) in Operations

PET injection molding machines in the range of 250 tons to 650 tons exhibit remarkable operational capabilities that streamline the plastic manufacturing process. These machines boast a user-friendly interface that allows operators to easily set and adjust molding parameters, ensuring precise control over the injection process. With fast cycle times and high-speed injection capabilities, they enable manufacturers to achieve efficient production rates without compromising on quality. The robust construction of these machines ensures stability and durability during operation, even under heavy workloads. Additionally, advanced safety measures and protective features ensure a secure working environment for operators. Whether it’s producing PET bottles, containers.These machines deliver consistent performance, exceptional precision, and reliable operation, making them indispensable assets for businesses in the plastic manufacturing industry.

- How to use PET Injection Molding Machine

Operating a PET injection molding machine (250Ton – 650Ton) requires a systematic approach to ensure smooth and efficient production. Here is a step-by-step instruction sheet to assist you in successfully completing the process.

- Wide range of tonnage options available, from 130 tons to 4000 tons

- Utilizes advanced servo motor technology for precise and efficient operation

- High-speed injection for improved productivity

- Energy-efficient design reduces power consumption

- Exceptional precision and repeatability for consistent quality

- Versatile machine capable of handling various types of plastics

- Robust construction for durability and longevity

- User-friendly interface for easy operation and monitoring

- Advanced control system for precise parameter adjustment

- Safety features to ensure operator protection

- Optional customization and configuration to meet specific production requirements

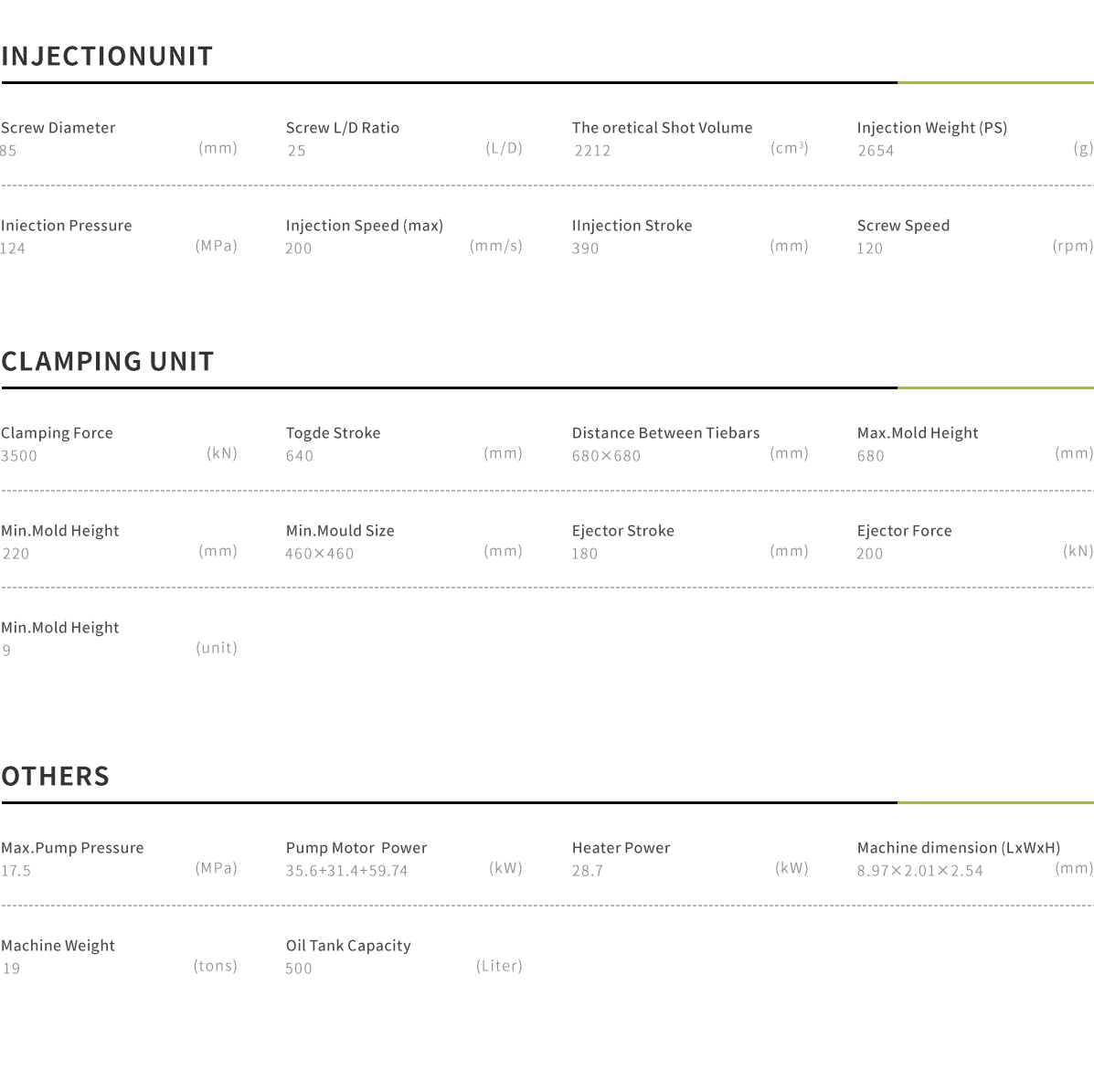

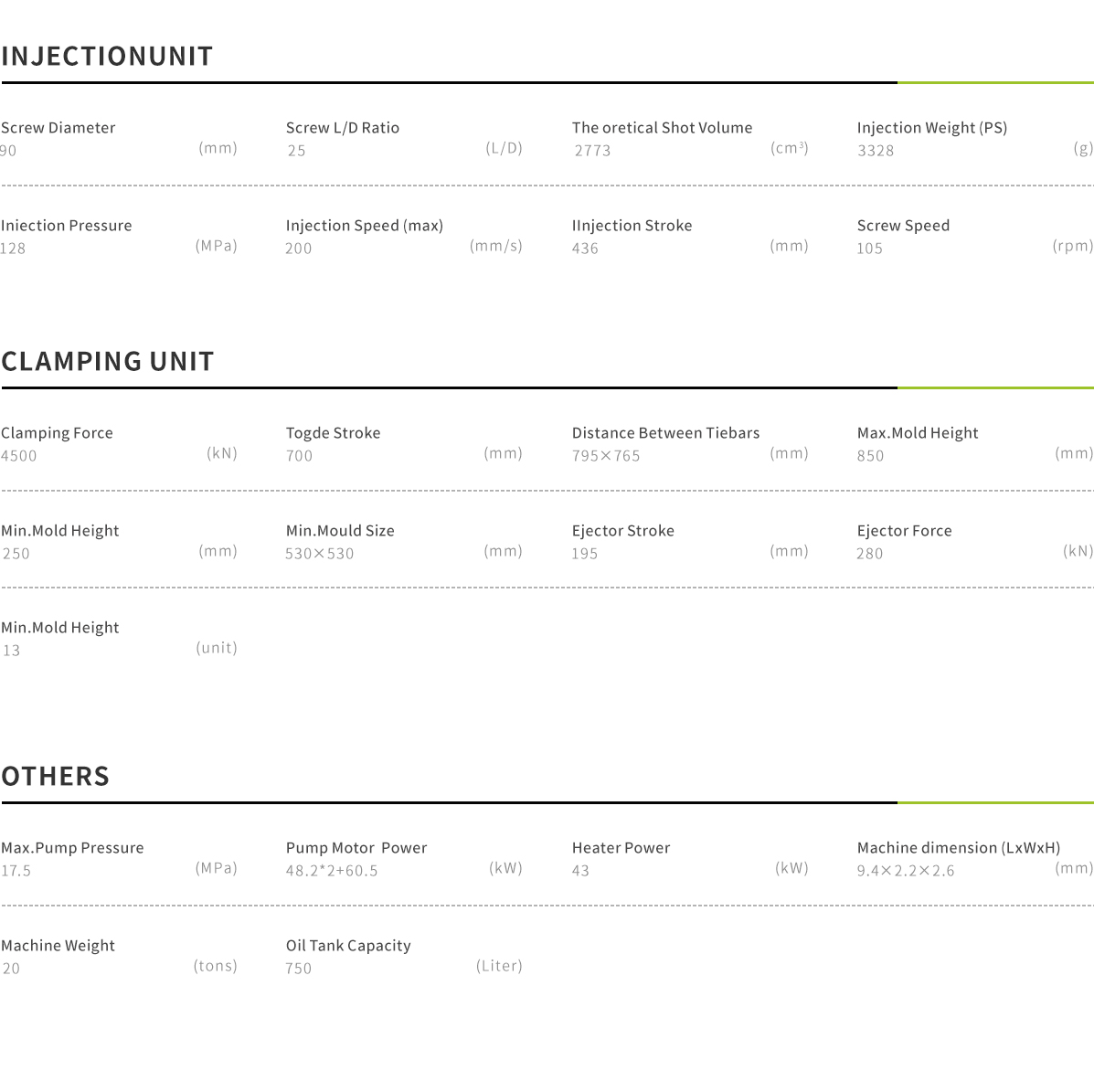

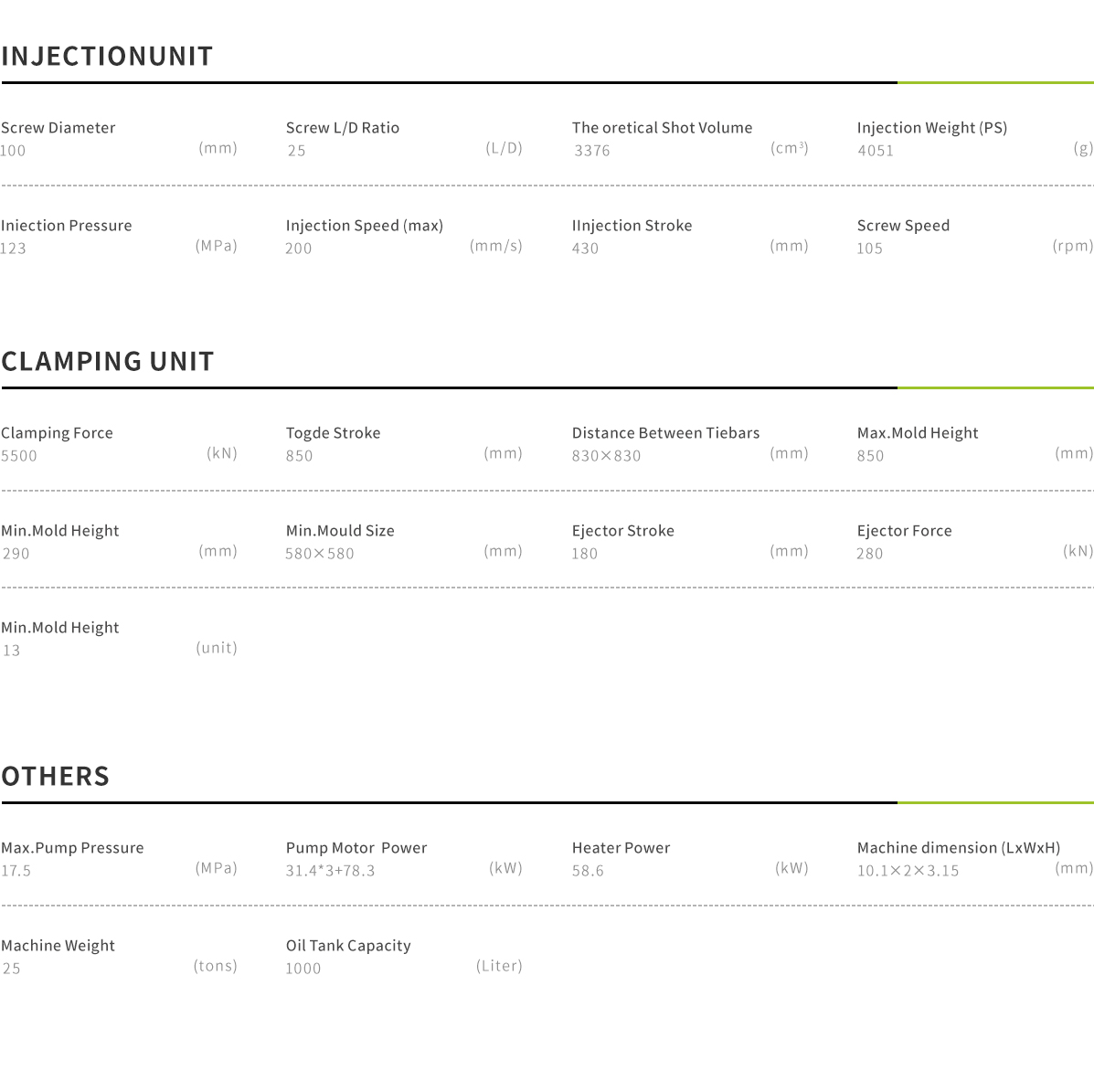

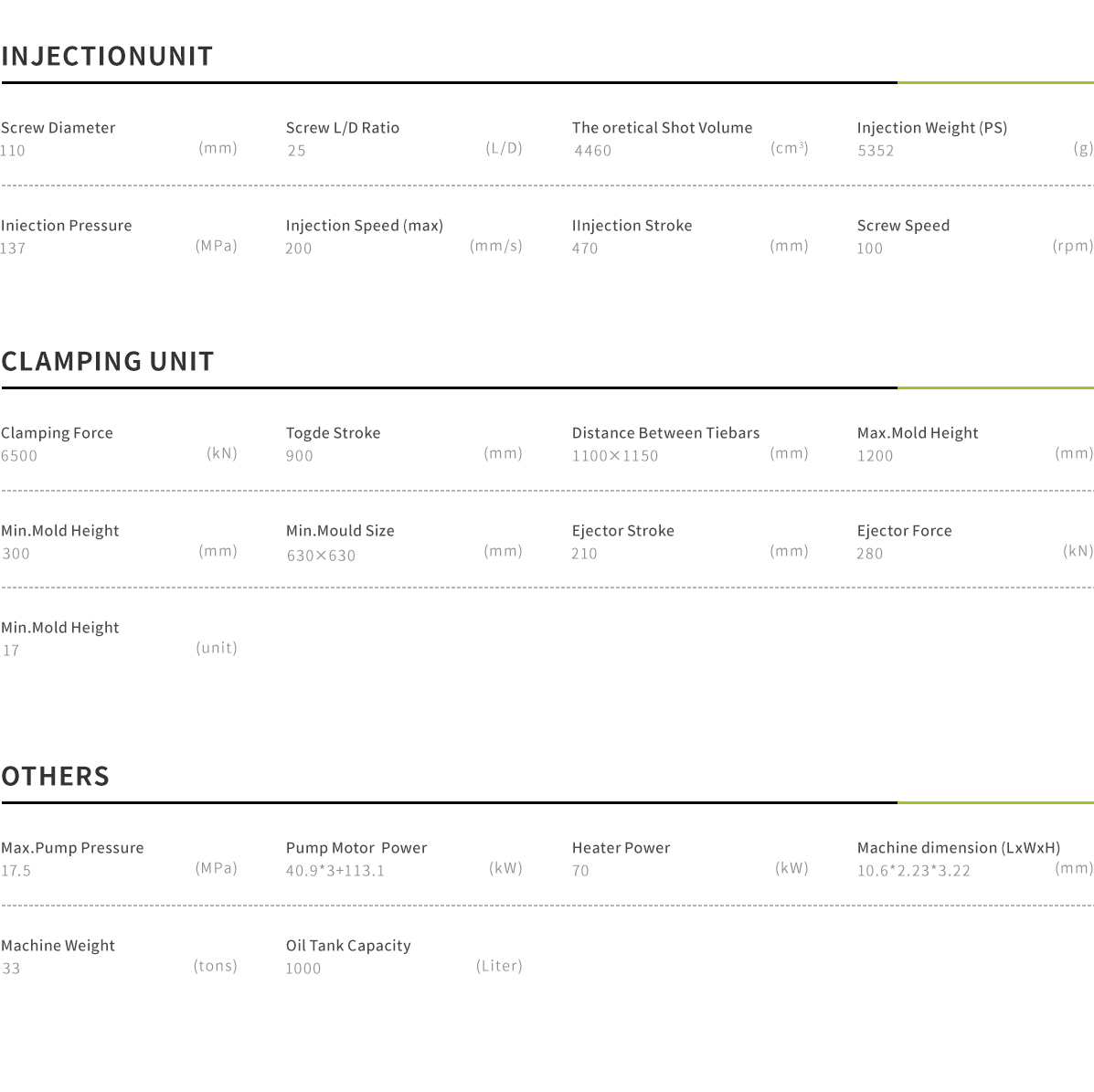

- PET Fast Injection Molding Machine Specification

- DKM PET Injection Molding Machine in Operation

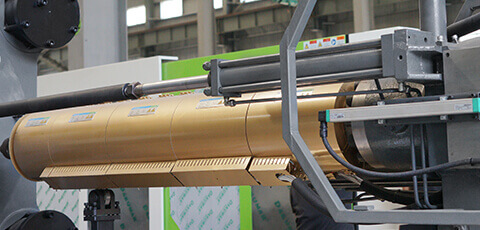

With electrical pre plastic charging system, DKM-PET Injection Molding Machine realize fast and precise injection molding.

- Advantages of using PET Injection Molding Machine (250Ton - 650Ton):

There are several reasons to choose this injection molding machine. However, some of the most considered ones are:

Precise control over the injection process ensures the production of medical plastic parts with excellent quality and accuracy.

Fast cycle times enable efficient production rates, meeting the demanding needs of the medical industry. This allows for timely delivery of medical plastic parts.

The injection molding process incorporates energy-saving features, reducing operating costs and contributing to sustainability efforts. This helps in minimizing environmental impact while optimizing resource utilization.

Injection molding offers versatile capabilities that accommodate various medical applications. It can be used for producing medical devices, components, and packaging, providing flexibility in meeting different requirements.

User-friendly interfaces and intuitive controls make the injection molding process easy to operate and monitor. This enhances efficiency and reduces the learning curve for operators.

Injection molding machines are built with robust construction to ensure durability and stability, even under heavy production loads. This ensures consistent performance and minimizes downtime.

Safety measures and features are integrated into injection molding machines to prioritize the well-being of operators and maintain a secure working environment. This reduces the risk of accidents and injuries.

Injection molding delivers consistent performance and exceptional precision, ensuring the reliability and quality of medical plastic products. This is crucial for meeting stringent quality standards in the medical industry.

- What you need to know about PET Injection Molding Machine (250Ton - 650Ton)?

DKM One Stop Solution

Injection System:

DKM PET injection molding machines adopt specialized L/D ratio screws with extra long L/D ratio and high plasticizing rate, which can achieve efficient plasticizing process and improve the plasticizing effect and injection efficiency, and ensure that PET materials can be melted and plasticized evenly and efficiently. Enhance product quality and moulding efficiency. Single-screw structure and double-screw structure are both available for users to choose. DKM uses unique twin-screw design and melting technology, high-efficiency plasticizing system, first-in-first-out technology, effectively reducing the AA value of preforms, solving the AA value challenges in the industry, and realizing high quality and high productivity PET preform production.

Precise Temperature Control System:

PET material has high requirements on the temperature. DKM PET specialized injection molding machine adopts four or more stages with PID temperature control in the feed barrel to achieve a precise temperature in key areas such as barrel, nozzles and molds. The high-precision temperature control ensures the uniformity and fluidity of the plastic melting, thus getting a better quality of molded products.

Cooling System:

DKM upgrades the cooling system by using efficient cooling circuits and fans, ensuring the molds and injection molding machines can be cooled quickly in a short time, thus increasing productivity and avoiding product distortion and shrinkage.

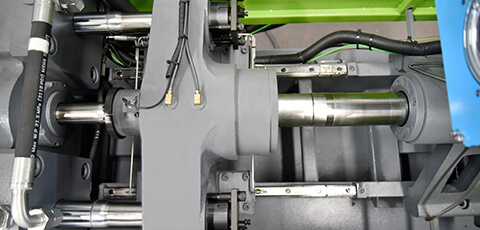

Clamping System:

DKM PET injection molding machine upgrades its clamping structure, with strong clamping force and stable machine performance. It ensures that the mold remains tightly closed during injection process and the precision and quality of products are well guaranteed. Furthermore, DKM PET plastic machine use extended frame, large space for four columns and larger mold capacity to make the molding process smoother.

Production Range:

DKM PET injection molding machine has a wide range of production for all kinds of PET moulded products, such as PET preforms, storage boxes, daily necessities and so on. Characterised by high precision, quality and efficiency, they are able to meet the various requirements of customers for packaging materials. In addition, due to the excellent performance, the products produced by DKM machines have the advantages of good consistency and durability.

Why should consider buying PET injection molding?

High precision control

PET injection molding machines provide accurate and consistent results with tight tolerances, ensuring the production of high-quality plastic parts.

Fast cycle times

These machines enable manufacturers to achieve high production rates and meet demanding deadlines, resulting in improved efficiency and productivity.

Energy-saving features

PET injection molding machines are designed with efficient hydraulic systems and variable pump drives, reducing operating costs and environmental impact.

Versatility

These machines can handle a wide range of plastic materials, making them suitable for diverse applications in various industries.

User-friendly interfaces

PET injection molding machines feature intuitive control panels and touchscreens, enhancing usability and productivity for operators.

Robust construction

The machines are built with durable materials and components, ensuring longevity, reliability, and consistent performance even under heavy production loads.

Competitive Pricing

DKM offers competitive pricing for the DKM-DH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

Provide Complete Supporting Equipment and Service for Your Injection Molding Machine

DKM One Stop Solution

24Hours Services

Training Equipment Maintenance And System Upgrade

- Conclusion:

In conclusion, the DKM machine stands as an exceptional choice for manufacturers in need of a reliable, efficient, and versatile solution. With its robust construction, technology, and user-friendly interface, it offers precise control, enhanced repeatability, and high-quality production. Its energy-saving features contribute to cost savings and sustainability efforts. The machine’s adaptability to various applications allows for versatility and the ability to cater to different industry demands. With comprehensive after-sales support, this machine ensures a seamless experience and optimized performance. By considering this machine, manufacturers can elevate their production capabilities, achieve superior results, and make a valuable investment in their manufacturing operations.