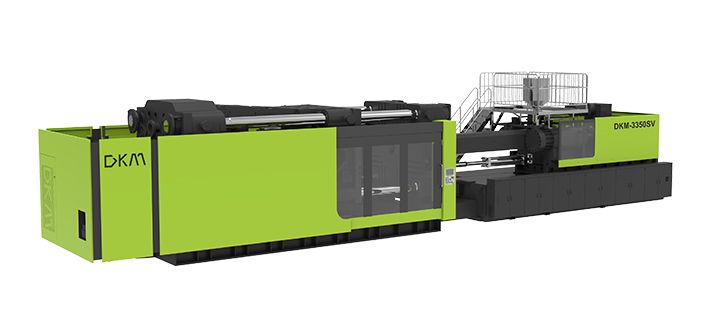

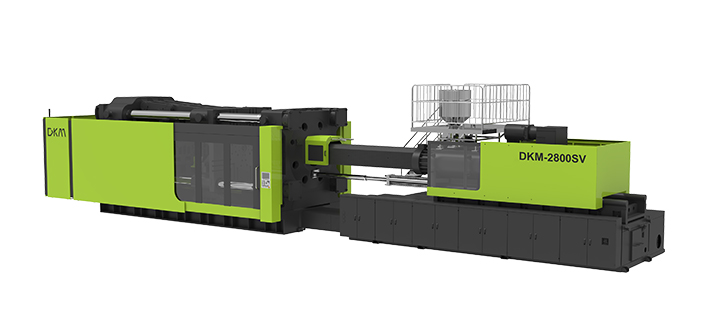

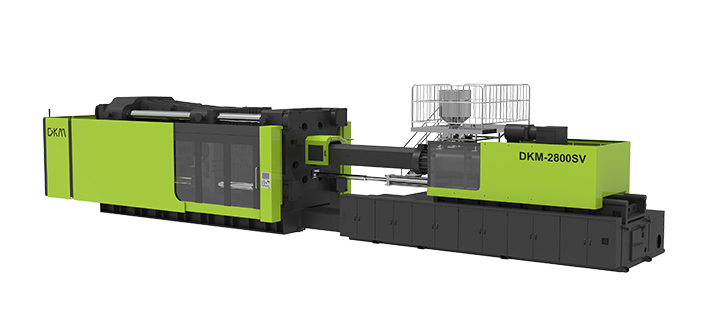

Servo Motor Injection Molding Machine(130Ton-4000Ton)

With our cutting-edge Servo Motor Injection Molding Machines, spanning from 130 to 4000 ton, developed to suit all your plastic injection molding needs, welcome to the world of advanced production. Our machines provide unmatched efficiency, dependability, and versatility thanks to cutting-edge technology and precise engineering, ensuring that your manufacturing processes reach new levels of productivity and perfection. With our sector-leading solutions, which provide top-tier performance for all your manufacturing needs, embrace the future of injection molding.

Clamping Force

1300-40000kN

Structure

Toggle(Three-Platen)

Machine Drive

Hydraulic Servo System

- Servo Motor Injection Molding Machine (130Ton-4000Ton)

Our product portfolio, which covers loads between 130 and 4000 ton, providing a comprehensive solution for all of your injection molding needs. These devices, which make use of servo motor technology, raise the bar for production efficiency with their unrivalled precision, speed, and energy economy. Our Servo Motor Molding Machines are the perfect choice for your manufacturing operations, whether you’re producing little components or big-ticket items. They are made to operate superbly and to be dependable and versatile. You can see the future of injection molding with our cutting-edge solutions, which are designed to boost your production and grow your company. Here are a few qualities to consider.

- Wide range of tonnage options available, from 130 tons to 4000 tons

- Utilizes advanced servo motor technology for precise and efficient operation

- High-speed injection for improved productivity

- Energy-efficient design reduces power consumption

- Exceptional precision and repeatability for consistent quality

- Versatile machine capable of handling various types of plastics

- Robust construction for durability and longevity

- User-friendly interface for easy operation and monitoring

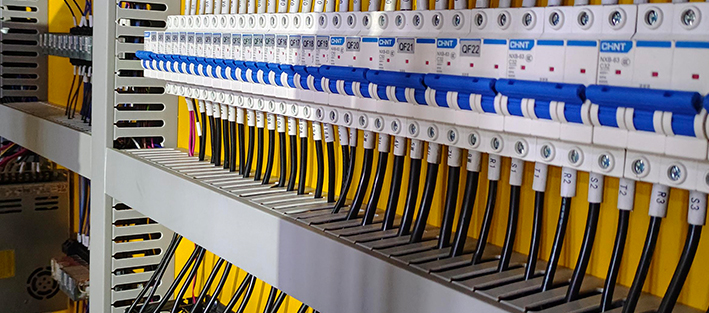

- Advanced control system for precise parameter adjustment

- Safety features to ensure operator protection

- Optional customization and configuration to meet specific production requirements

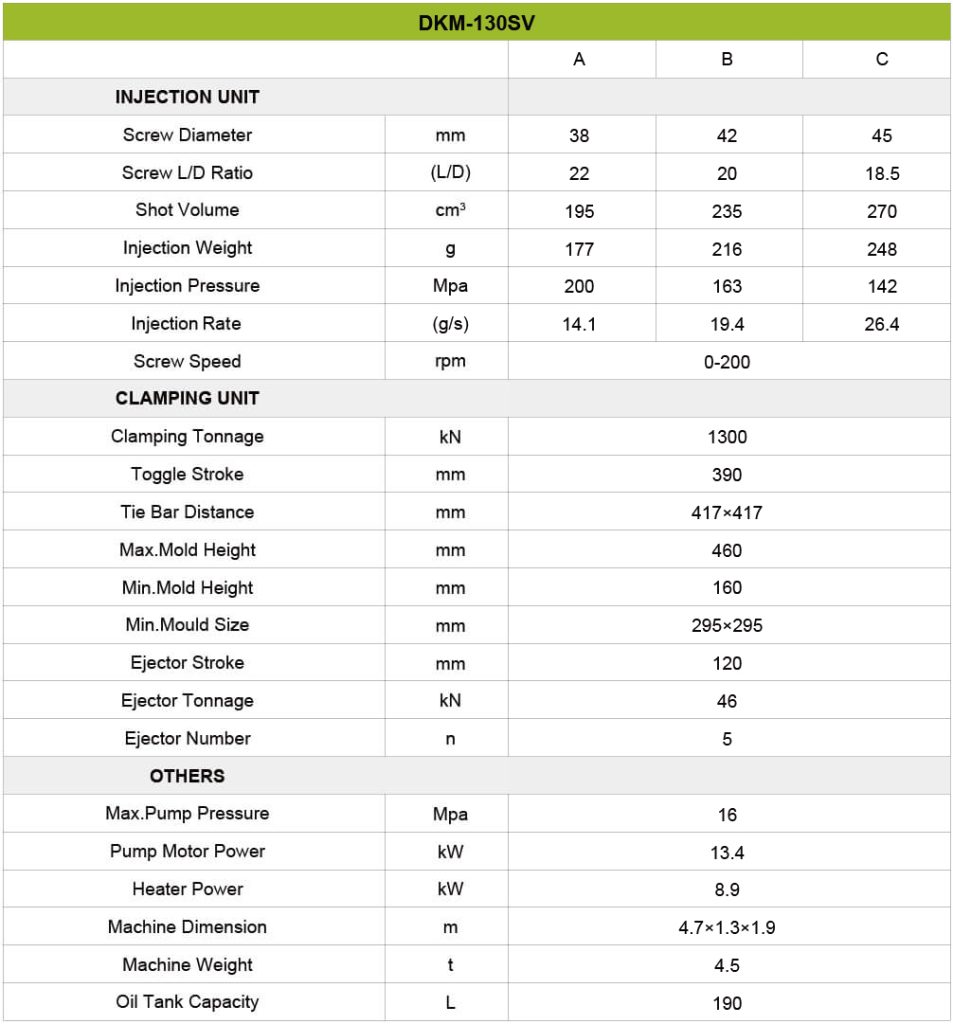

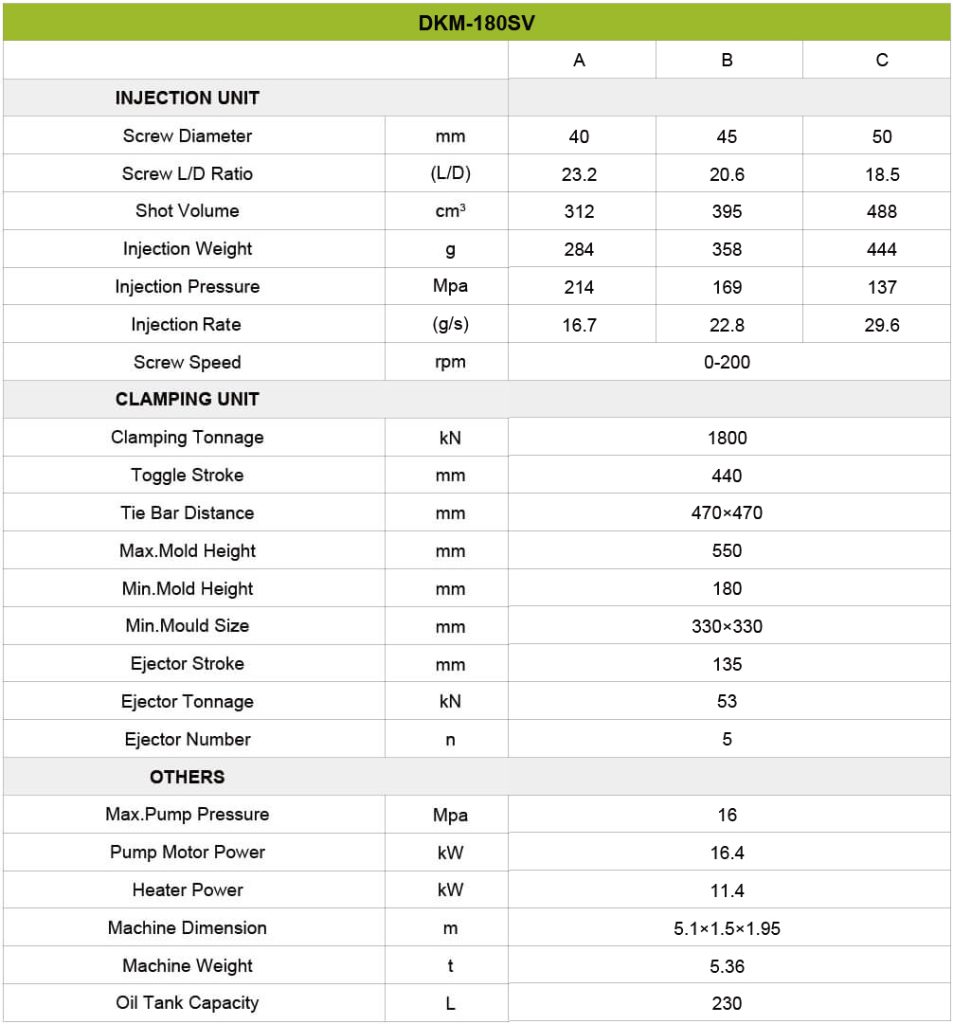

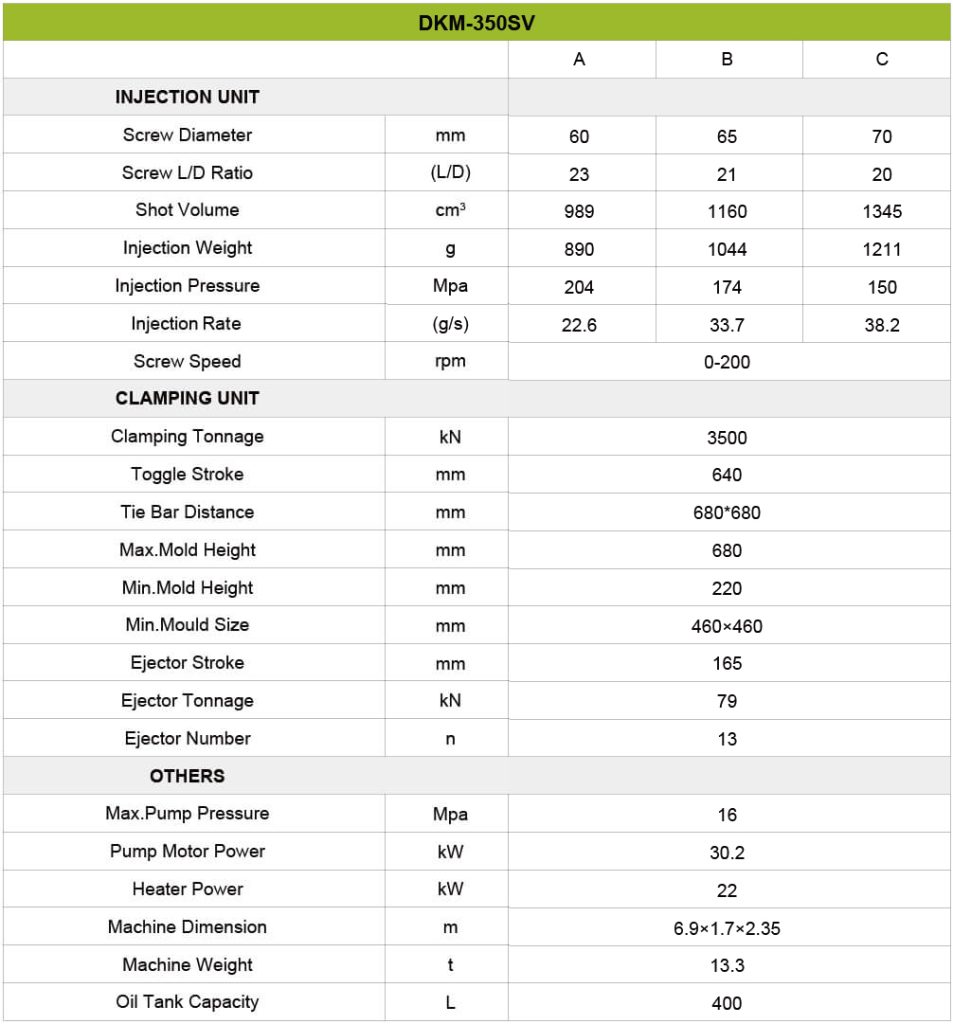

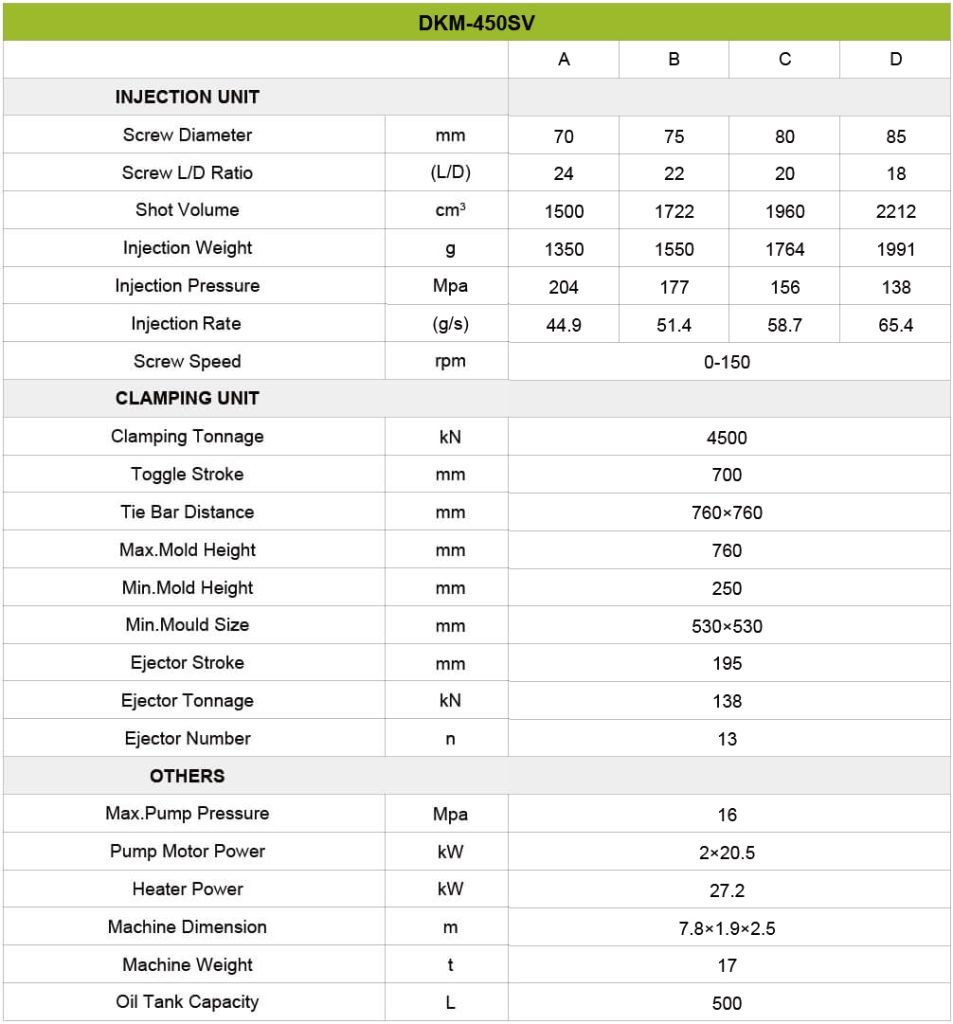

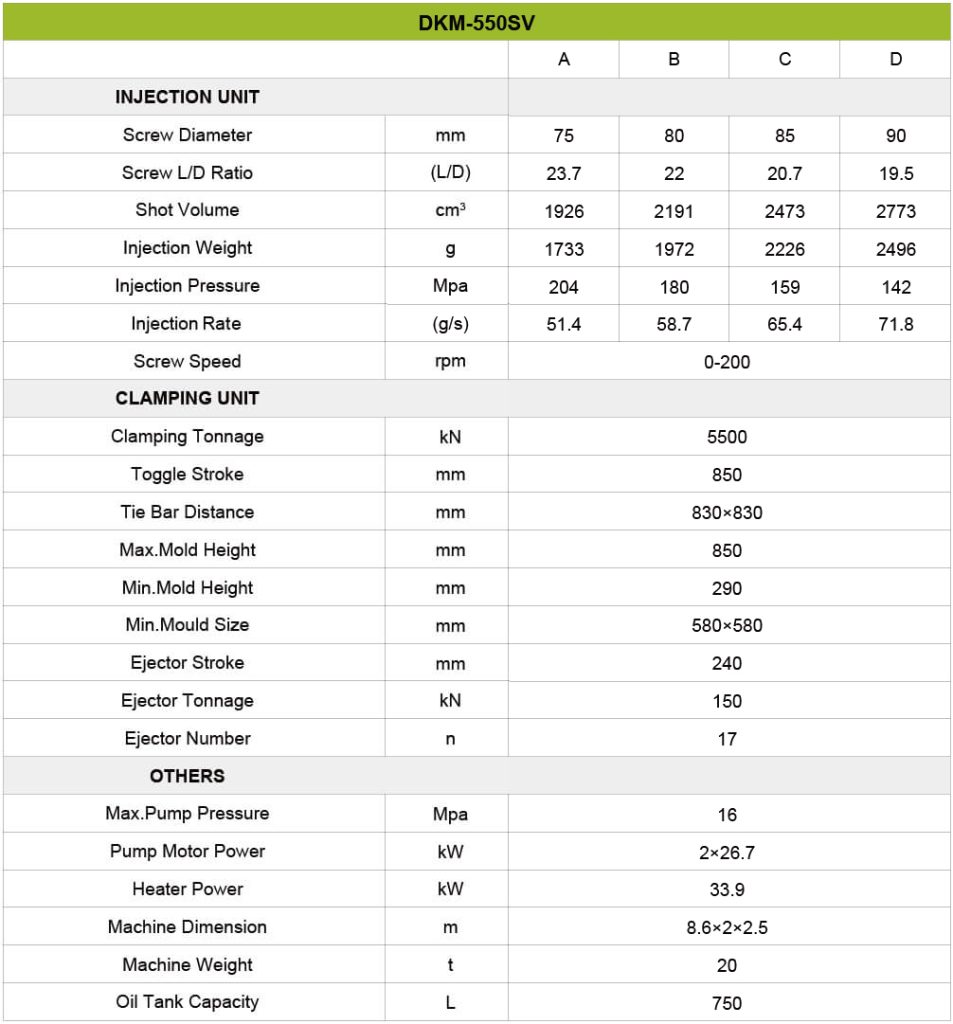

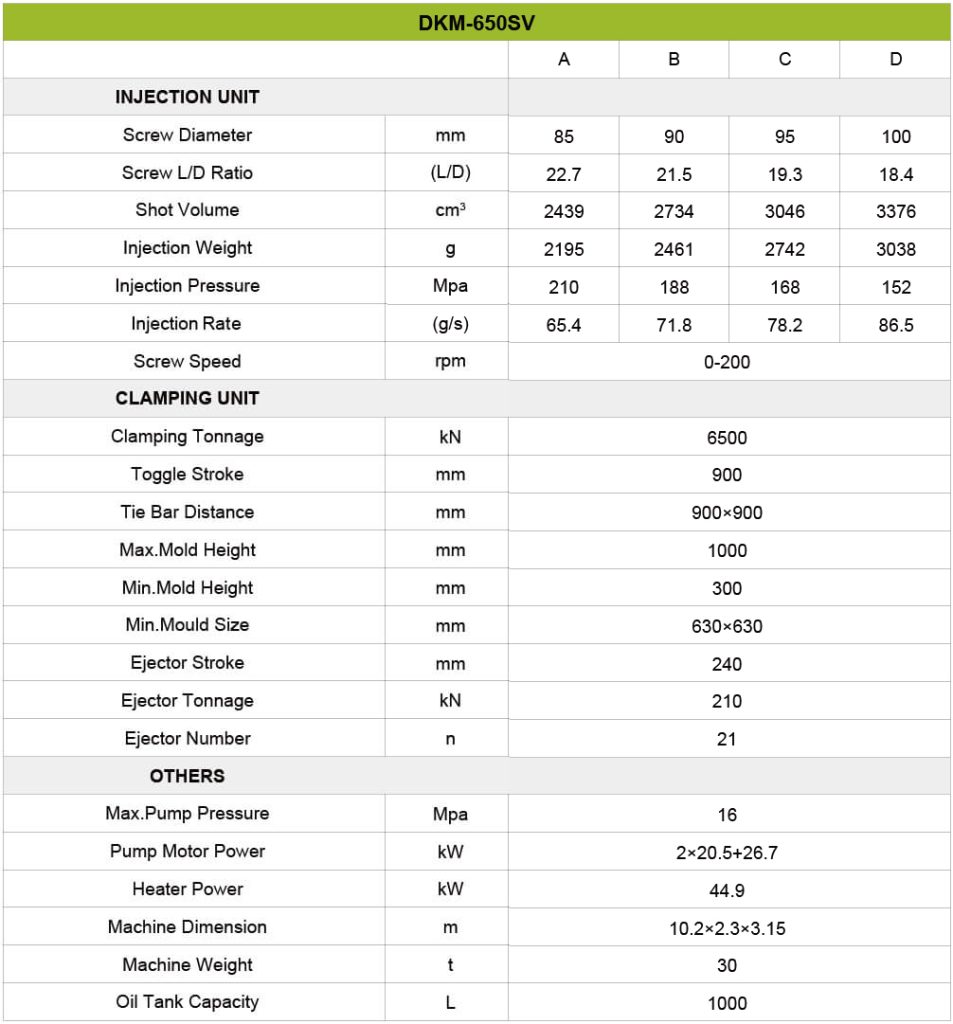

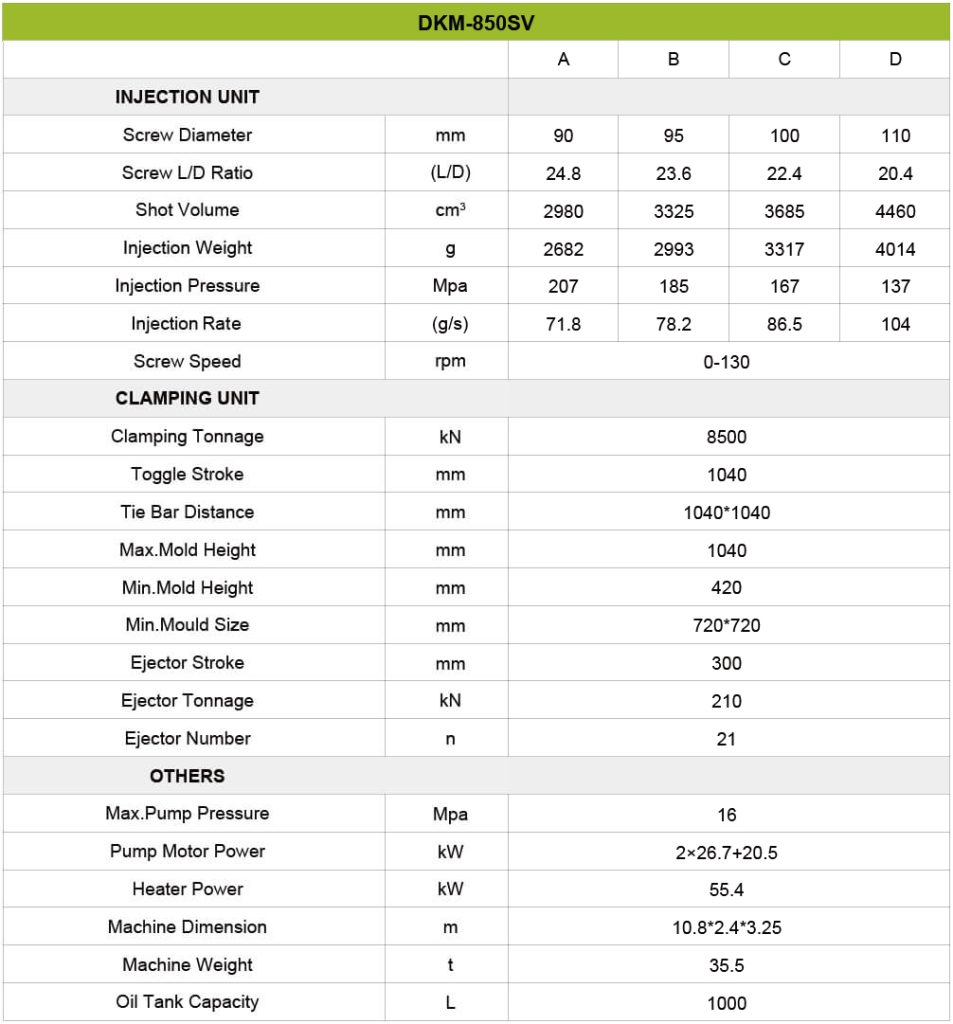

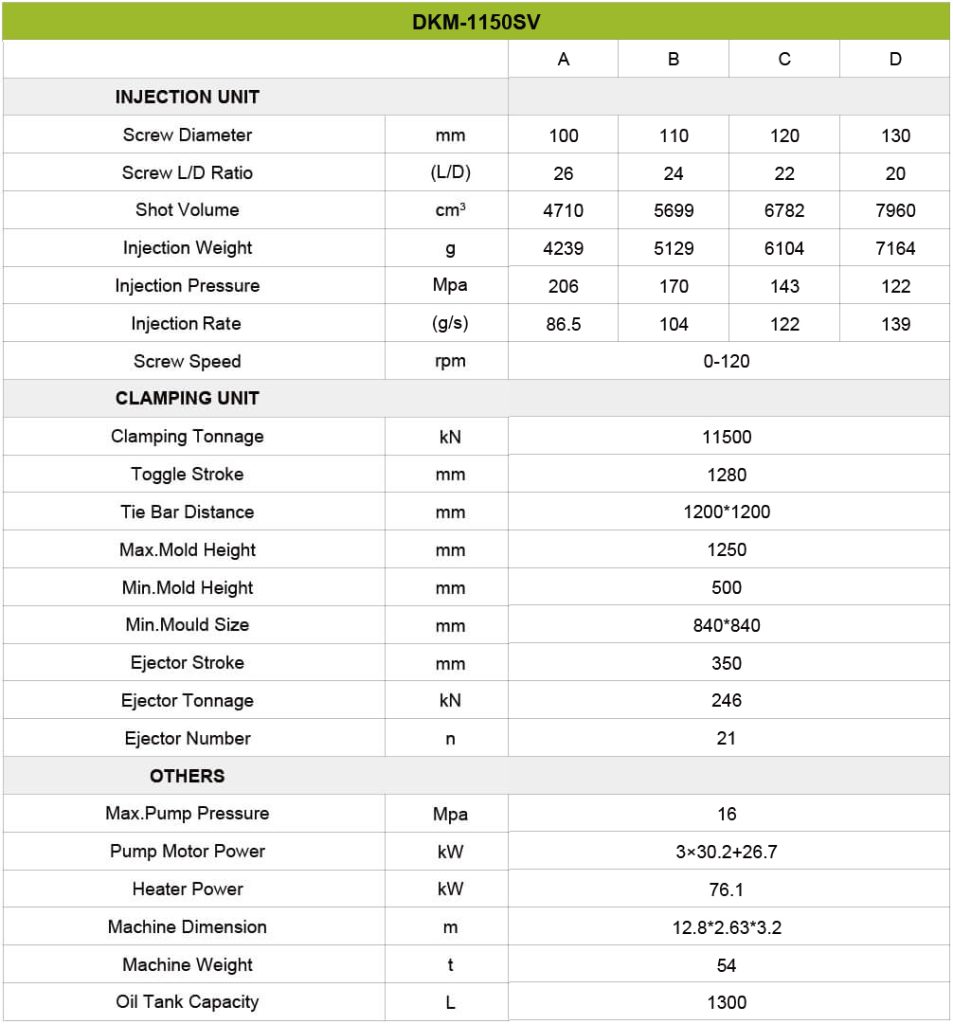

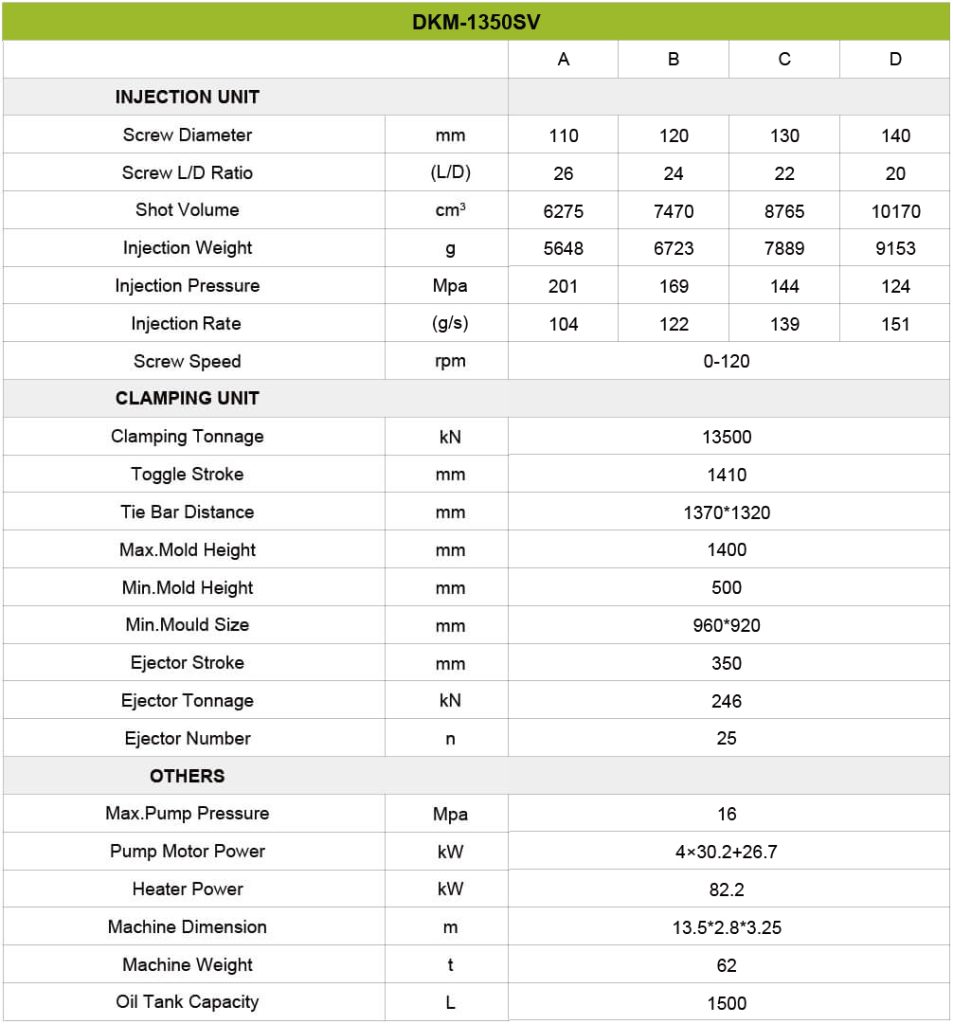

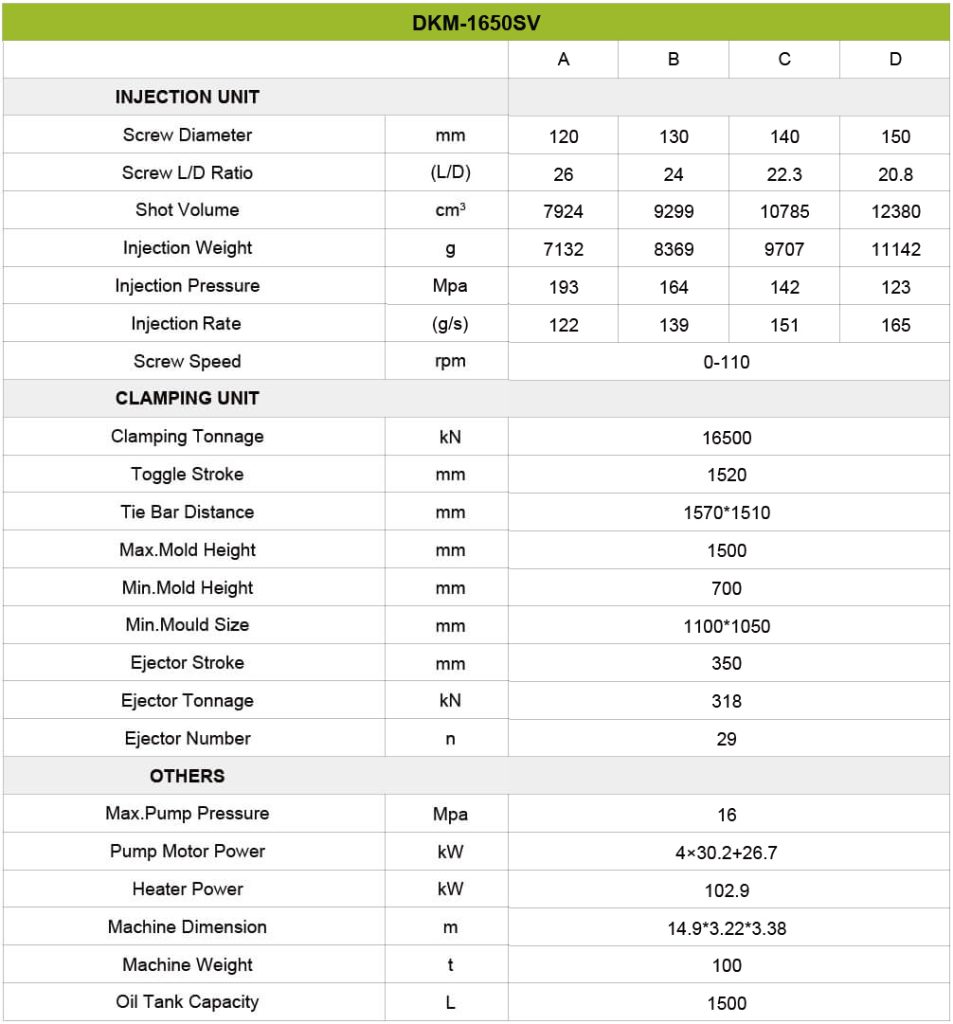

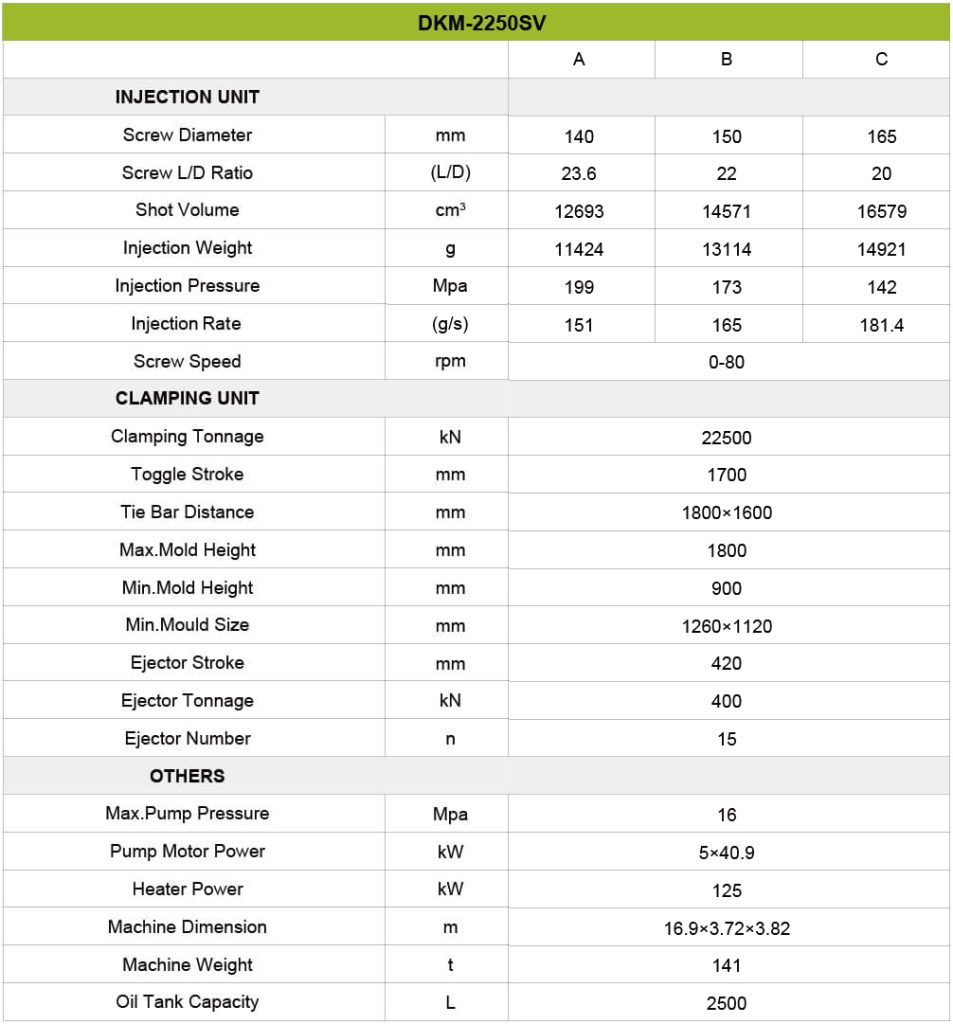

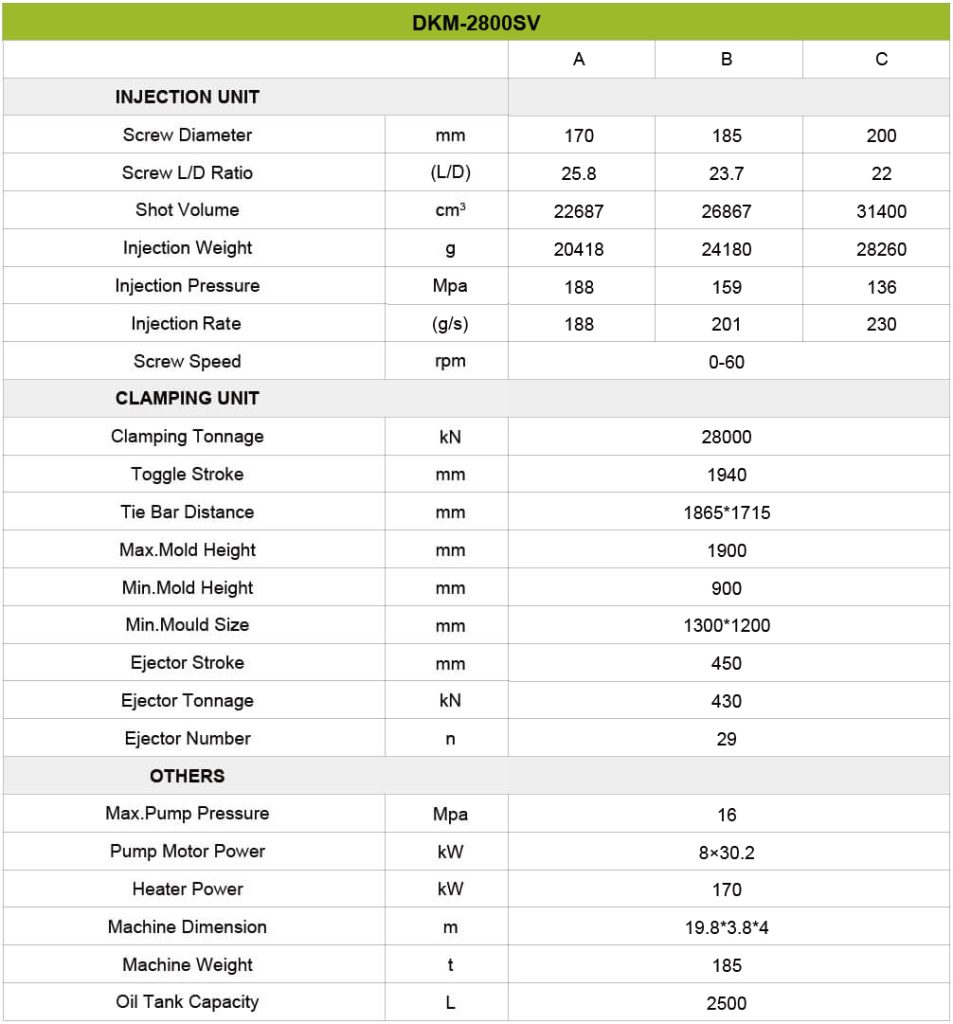

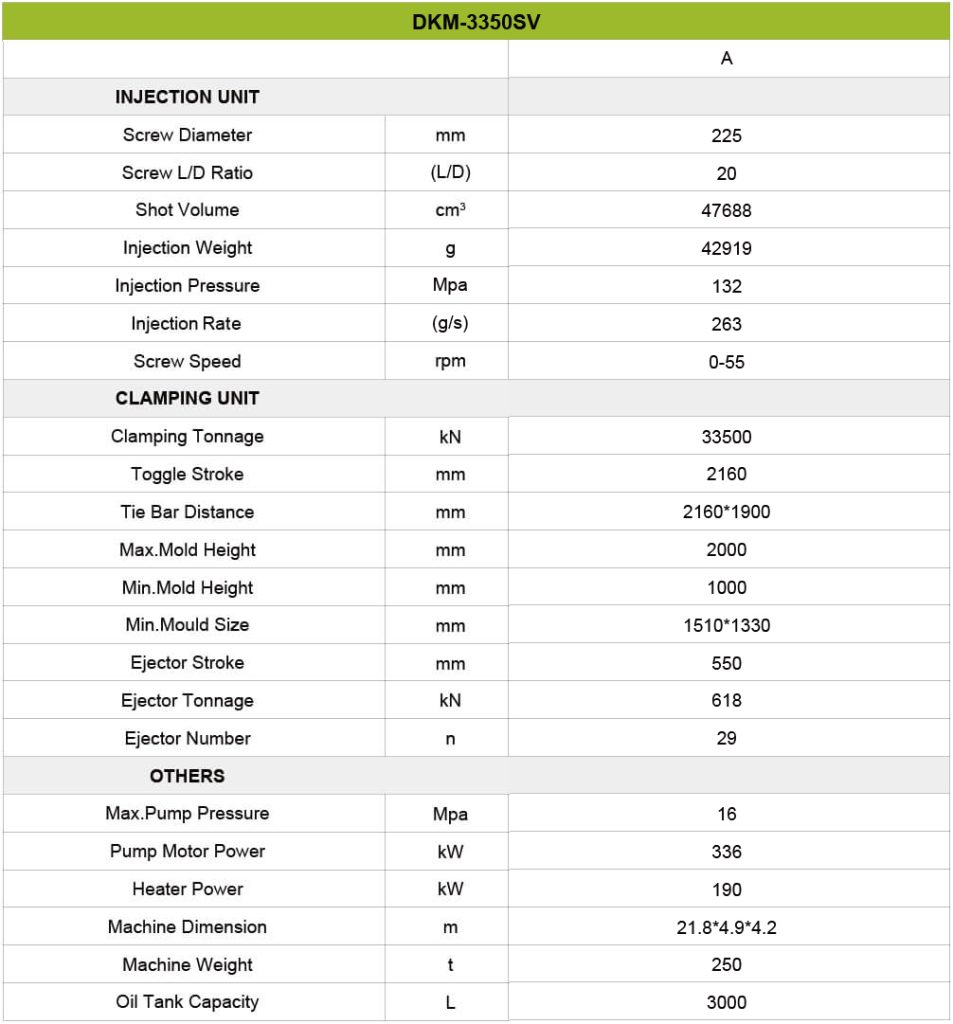

- Servo Motor Injection Molding Machine Specification

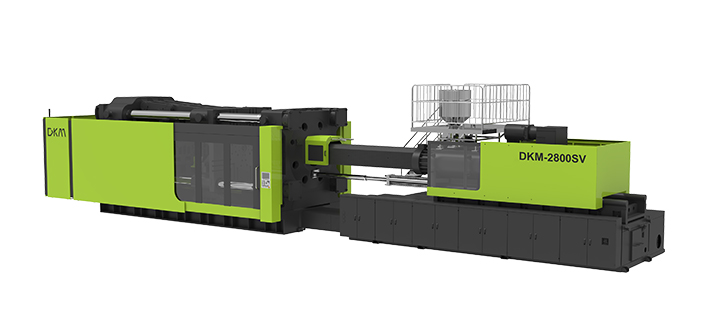

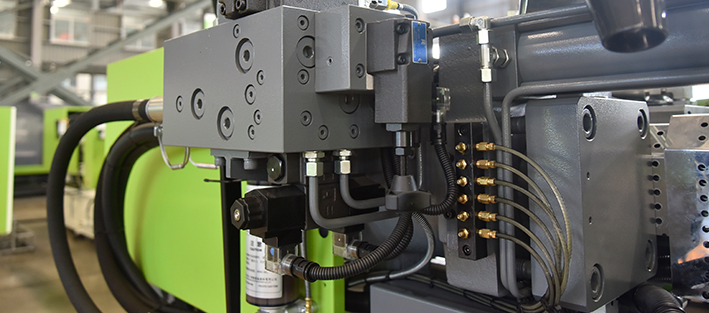

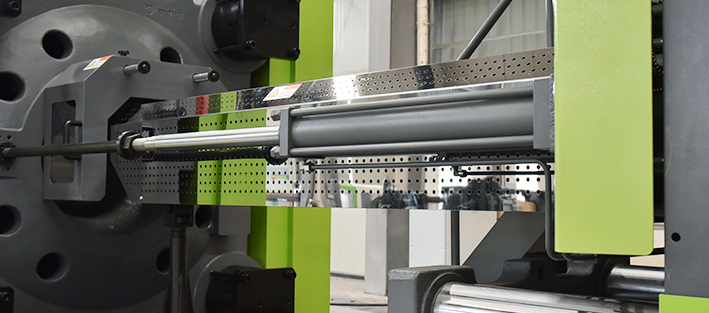

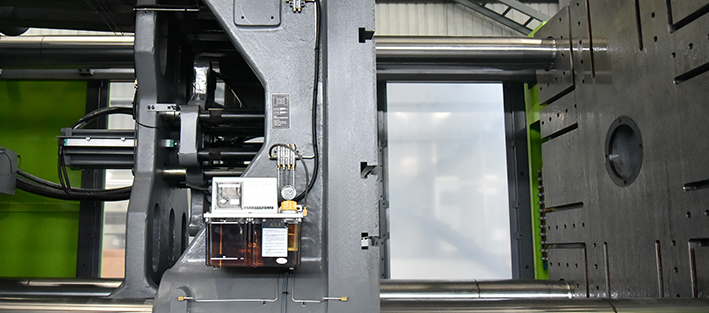

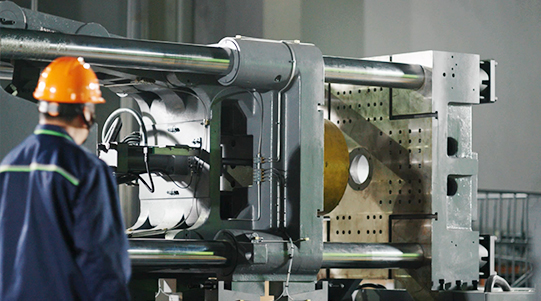

- Servo Motor Injection Molding Machine in operations

Servo Motor Injection Molding Machines showcase their remarkable capabilities and efficiency. The integration of servo motor technology enables precise and dynamic control over the injection process, resulting in consistent and high-quality outputs. These machines offer rapid injection speeds, minimizing cycle times and maximizing productivity. Their energy-efficient design also optimizes power use, cutting down on operating expenses. They are appropriate for a variety of sectors and applications because to their adaptability, which allows them to accommodate a wide range of plastic materials. Operators will appreciate the user-friendly interface and advanced control system, allowing for easy parameter adjustments and monitoring. Safety features are also incorporated to ensure a secure working environment. Whether you require small-scale production or large-scale manufacturing, our servo motor plastic machine delivers exceptional performance and reliability, empowering you to meet your production goals efficiently and effectively.

- Advantages of using Servo Motor Injection Molding Machine(80Ton-4000Ton):

The advantages of using a Servo Motor Injection Molding Machine (ranging from 130 tons to 4000 tons) are numerous and can significantly enhance your manufacturing operations. Here are the key advantages in detail:

Servo motor technology ensures optimal energy consumption by adjusting the motor speed based on the required load. It results in significant energy savings compared to traditional hydraulic systems, leading to lower operating costs and a smaller carbon footprint.

The servo motor’s precise control allows for accurate and repeatable injection movements, resulting in consistent part quality. This is particularly crucial for industries requiring tight tolerances and high precision, ensuring uniformity in every manufactured piece.

Servo-driven machines offer rapid acceleration and deceleration rates, enabling shorter cycle times. This translates into increased production output and improved efficiency, helping you meet higher demand without compromising on quality.

Servo motors provide excellent control over injection speed, pressure, and position. This level of control allows for fine-tuning of parameters, optimizing the molding process, and reducing the likelihood of defects or rejects.

Compared to traditional hydraulic systems, servo motor-driven machines operate with significantly lower noise levels. This creates a quieter and more comfortable working environment for operators, reducing noise-related stress and enhancing overall workplace satisfaction.

Servo Motor Injection Molding Machines can handle a wide range of plastic materials, including both commodity and engineering-grade plastics. This versatility enables manufacturers to produce diverse products across different industries, expanding their market opportunities.

Servo-driven systems have fewer mechanical components, resulting in reduced wear and tear. Consequently, the maintenance requirements are typically lower compared to hydraulic machines, saving both time and maintenance costs.

Servo motors offer enhanced safety features, such as precise position control and overload protection. These safety mechanisms ensure the well-being of operators, preventing accidents and injuries during machine operation.

Modern Servo Motor Injection Molding Machines are equipped with user-friendly interfaces, making it easier for operators to set parameters, monitor processes, and make adjustments. This intuitive interface streamlines operation and reduces the learning curve, enabling efficient production.

Servo motors are known for their durability and longevity. The robust construction and high-quality components of servo-driven machines contribute to their reliability, reducing downtime and maximizing productivity.

- What you need to know about Servo Motor Injection Molding Machine (130Ton-4000Ton)?

DKM One Stop Solution

When working with a Servo Motor Injection Molding Machine (130Ton-4000Ton), there are several key aspects you should be aware of:

Machine Specifications:

Familiarize yourself with the specific specifications of the machine you are operating, including its tonnage range (130 tons to 4000 tons) and other relevant parameters such as maximum injection pressure, injection speed, and mold opening stroke. Understanding these specifications will help you optimize your production process.

Servo Motor Technology:

Gain a comprehensive understanding of the servo motor technology employed in the machine. Servo motors offer precise control, energy efficiency, and improved responsiveness, enabling enhanced performance and cost savings compared to traditional hydraulic systems.

Mold Compatibility:

Ensure that the mold you are using is compatible with the machine’s specifications. Consider factors such as mold size, clamping force requirements, and any specific mold features or accessories needed for proper installation and operation.

Material Compatibility:

Different Plastic injection molding machines are designed to process specific types of plastic materials. Verify that the machine is suitable for the type of material you intend to use. Additionally, understand the material’s melt temperature, flow characteristics, and any specific processing requirements to optimize the injection process.

Machine Operation:

Understand the operating procedures and controls specific to the machine you are working with. Learn how to set and adjust parameters such as injection speed, pressure, holding time, and temperature settings. Additionally, become familiar with the machine’s control panel, interface, and any available automation features.

Maintenance and Troubleshooting:

Regular maintenance is essential for the smooth operation of the machine. For normal maintenance chores like lubrication, filter changes, and hydraulic system check, according to the manufacturer’s instructions. Learn how to identify and fix any problems that might occur while operating by being familiar with standard troubleshooting techniques.

Training and Resources:

Ensure that operators receive appropriate training on the operation, maintenance, and safety aspects of the machine. Utilise the tools at your disposal, such as user manuals, technical assistance, and training courses offered by the machine’s manufacturer, to expand your understanding and competence.

Why should consider buying Servo Motor Injection Molding Machine?

Buying a Servo Motor Injection Molding Machine (130Ton-4000Ton) offers several compelling reasons to consider. Here are the key benefits and advantages:

Servo Motor Injection Molding Machines are designed to handle various types of plastics, including both commodity and engineering-grade materials. This versatility allows you to cater to diverse market demands and expand your product offerings across different industries.

These machines are built with robust construction, ensuring durability and longevity. The sturdy design can withstand the demands of high-pressure injection molding operations, reducing downtime and maintenance costs.

The machine lineup covers a broad range of tonnage options.from 80 tons to 4000 tons. This versatility allows you to selectthe appropriate machine size based on your specificproduction requirements, whether you need to produce smallcomponents orlarge-scale items.

These machines utilize advanced servo motor technologywhich provides precise and efficient operation. Servo motorsoffer excellent control over the injection process, resulting inconsistent and high-quality outputs.The dynamic control andresponsiveness of servo motors enable improved precision.repeatability.and reduced waste

Servo Motor Injection Molding Machines offer hiqh-speed injection capabilities, which contribute to improved productivityFaster injection speeds help minimize cycle times, allowing youto produce more parts in less time. This increased efficiencytranslates into higher production output and reduced costs.

Servo motor technology is known for its energy efficiency.These machines optimize power consumption by adjusting themotor speed based on the required load. They use less energyas a consequence than conventiona hydraulic svstems. whichresults in financial savings and a less environmental effect.

The high precision and reproducibility of the injection moldingprocess are made possible by the precise control provided byservo motors. This is especially important for sectors that needprecise tolerances and high-quality end products. Consistentquality output minimizes rejects and rework, leading toimproved overall efficiency and customer satisfaction.

Versatile Machine Capabilities

Servo Motor Injection Molding Machines are designed to handle various types of plastics, including both commodity and engineering-grade materials. This versatility allows you to cater to diverse market demands and expand your product offerings across different industries.

Robust Construction

These machines are built with robust construction, ensuring durability and longevity. The sturdy design can withstand the demands of high-pressure injection molding operations, reducing downtime and maintenance costs.

Wide Range of Tonnage Options

The machine lineup covers a broad range of tonnage options.from 130 tons to 4000 tons. This versatility allows you to selectthe appropriate machine size based on your specificproduction requirements, whether you need to produce smallcomponents orlarge-scale items.

Advanced Servo Motor Technology

These machines utilize advanced servo motor technologywhich provides precise and efficient operation. Servo motorsoffer excellent control over the injection process, resulting inconsistent and high-quality outputs.The dynamic control andresponsiveness of servo motors enable improved precision.repeatability.and reduced waste

High-Speed Injection

Servo Motor Injection Molding Machines offer hiqh-speed injection capabilities, which contribute to improved productivityFaster injection speeds help minimize cycle times, allowing youto produce more parts in less time. This increased efficiencytranslates into higher production output and reduced costs.

Energy-Efficient Design

Servo motor technology is known for its energy efficiency.These machines optimize power consumption by adjusting themotor speed based on the required load. They use less energyas a consequence than conventiona hydraulic svstems. whichresults in financial savings and a less environmental effect.

Exceptional Precision and Repeatability

The high precision and reproducibility of the injection moldingprocess are made possible by the precise control provided byservo motors. This is especially important for sectors that needprecise tolerances and high-quality end products. Consistentquality output minimizes rejects and rework, leading toimproved overall efficiency and customer satisfaction.

Competitive Pricing

DKM offers competitive pricing for the DKM-SV series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

Provide Complete Supporting Equipment and Service for Your Injection Molding Machine

DKM One Stop Solution

24Hours Services

Training Equipment Maintenance And System Upgrade

- Conclusion:

In conclusion, this machine is a highly advantageous choice for businesses seeking advanced technology, versatility, and reliability in their manufacturing operations. With its wide range of tonnage options, the machine can caters to various project sizes and offers scalability for future growth. The incorporation of advanced technology, such as servo motor drive systems and high-speed injection capabilities, ensures exceptional performance, energy efficiency, and precise control. The user-friendly interface and controls make operation intuitive and efficient, while DKM’s comprehensive support and service guarantee a smooth experience from installation to ongoing maintenance. Furthermore, the cost-effectiveness of the machine, along with its long-lasting quality, makes it a smart investment for businesses aiming to maximize productivity and profitability. Overall, choosing this machine provides a reliable and efficient solution to meet diverse production needs and achieve success in the competitive manufacturing industry.