SFM Microcellular Injection Molding Technology

SFM Microcellular Injection Molding Technology is quietly driving a lightweight manufacturing revolution across multiple industries, from automotive and aerospace to medical diagnostic equipment. Imagine making plastic parts lighter, more durable, more production-efficient, and with minimal warpage—all without sacrificing strength. This may sound like an idealized manufacturing vision, but microcellular injection molding technology is turning it into reality.

What is SFM Microcellular Injection Molding Technology?

At the heart of the microcellular injection molding process lies the use of a supercritical fluid—typically nitrogen or carbon dioxide—injected under high pressure into the polymer melt. These gases form a uniform single-phase solution within the melt. When the melt is injected into the mold and pressure is released, hundreds of millions of microscopic bubbles, with diameters ranging only from 5 to 100 microns, are instantaneously generated. The bubble nucleation density can reach an impressive 10⁹ to 10¹⁵ per cubic centimeter.

Unlike traditional methods that rely on chemical blowing agents, microcellular foaming is a purely physical process. It uses only gases from the atmosphere without adding any chemicals, resulting in a purer final product. Furthermore, the foamed parts are easier to recycle and can be mixed with virgin polymer without altering its chemical properties.

The Four Steps of SFM Microcellular Injection Molding

The implementation of SFM Microcellular Injection Molding relies on a set of precision systems working in synergy and progresses through four key stages.

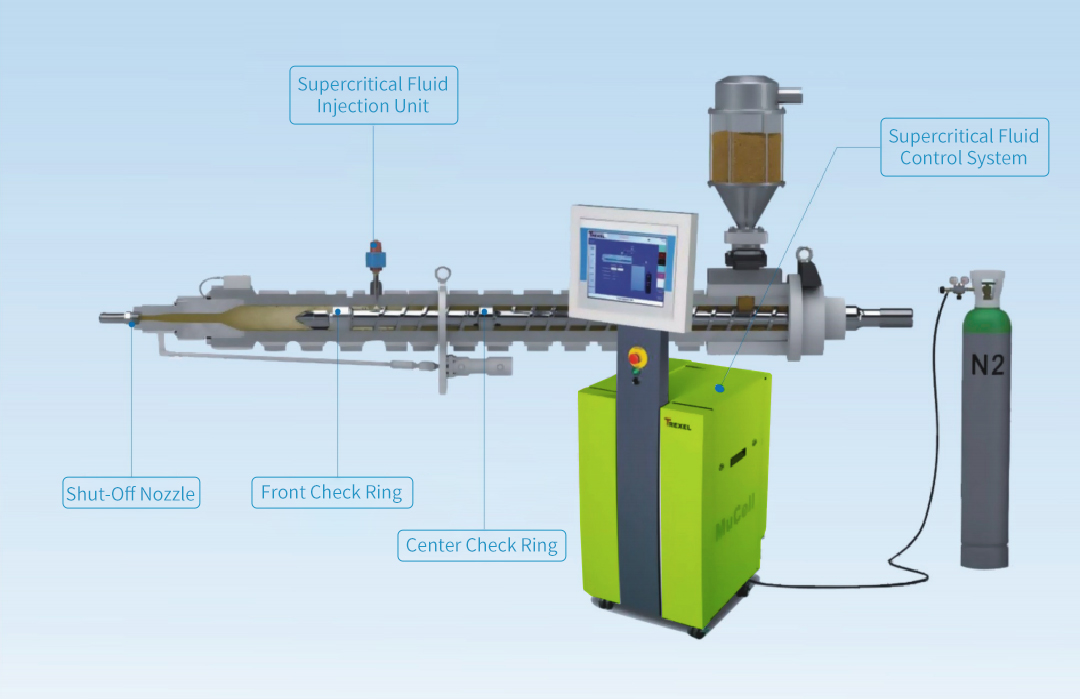

First, specialized equipment support is required: The system core includes a gas dosing system, interface components connected to the injection molding machine, and a specially designed injection unit equipped with a Supercritical Fluid Control System, Supercritical Fluid Injection Unit, Front Check Ring, Center Check Ring, and a Shut-Off Nozzle.

The entire foaming process can be broken down into four consecutive stages:

The supercritical fluid is injected into the barrel under high pressure. Controlled by the Supercritical Fluid Control System, it is thoroughly mixed with the polymer melt to form a uniform single-phase melt.

At this stage, the Center Check Ring creates a sealed mixing section on the screw, preventing gas escape while enhancing the screw's mixing action on the gas-polymer mixture.

When the single-phase melt is injected through the Shut-Off Nozzle into the lower-pressure mold cavity, the dissolved gas becomes supersaturated due to the pressure drop, instantly forming countless microscopic bubble nuclei.

Here, the Front Check Ring prevents the melt from flowing back into the screw during injection and holding phases, maintaining injection force and ensuring all the gas-laden melt is pushed into the mold.

The bubble nuclei grow in a controlled manner, filling internal spaces and forming a microcellular structure.

The mold continues to cool, permanently fixing the cellular structure and forming the final foamed product.

A well-executed process results in a uniform, closed-cell structure, which is the foundation for the product's exceptional performance.

Advantages of SFM Microcellular Injection Molding Technology

Adopting SFM Microcellular Injection Molding Technology delivers multi-dimensional, quantifiable benefits for manufacturers, directly translating into market competitiveness and profitability.

- Cost Reduction & Efficiency Gains are the most direct drivers. The process enables 5%-30% part weight reduction, directly saving resin costs.

Simultaneously, because the internal bubbles’ continued expansion provides “internal holding pressure,” the traditional holding phase is eliminated. Cooling time is shortened, reducing the overall cycle time by 15%-40%.

Additionally, the required injection pressure and clamping force are significantly lower—sometimes by 30%-50%. This means large parts can be produced on smaller injection molding machines, reducing equipment investment.

- Enhanced Quality & Performance: The technology effectively compensates for volumetric shrinkage during plastic cooling, greatly reducing or eliminating sink marks and voids.

Microcellular parts also exhibit extremely low residual stress, leading to a major improvement in warpage. Deformation can be reduced by 47% or more compared to traditional solid injection molding, achieving exceptional dimensional stability.

Furthermore, reduced melt viscosity and increased flow length aid in filling complex or thin-walled structures. For products requiring thermal insulation or acoustic damping, the internal closed-cell structure provides additional thermal insulation and sound-damping properties.

- Greater Design Freedom: Since gas expansion replaces traditional holding pressure, products made with this technology can have greater wall thickness variation. Designers are no longer constrained to uniform wall thickness solely to avoid sink marks.

The most breakthrough change is in rib design. In traditional design, to prevent surface sink marks, rib thickness is typically limited to 50% of the main wall thickness. With microcellular technology, a 1:1 rib-to-wall thickness ratio is achievable without sink marks. This allows for the design of stronger, high-performance ribs, opening new paths for lightweighting and structural reinforcement.

Applications of SFM Microcellular Injection Molding

Microcellular technology has moved from the laboratory to global production lines, proving its value in many demanding fields.

In the automotive industry, from door panels and instrument panel carriers to engine covers, the technology helps achieve 10%-30% weight reduction while improving dimensional stability and reducing warpage. For example, one instrument panel carrier project reduced clamping force requirements from 2500 tons to 1200 tons and shortened the cycle time by 15%.

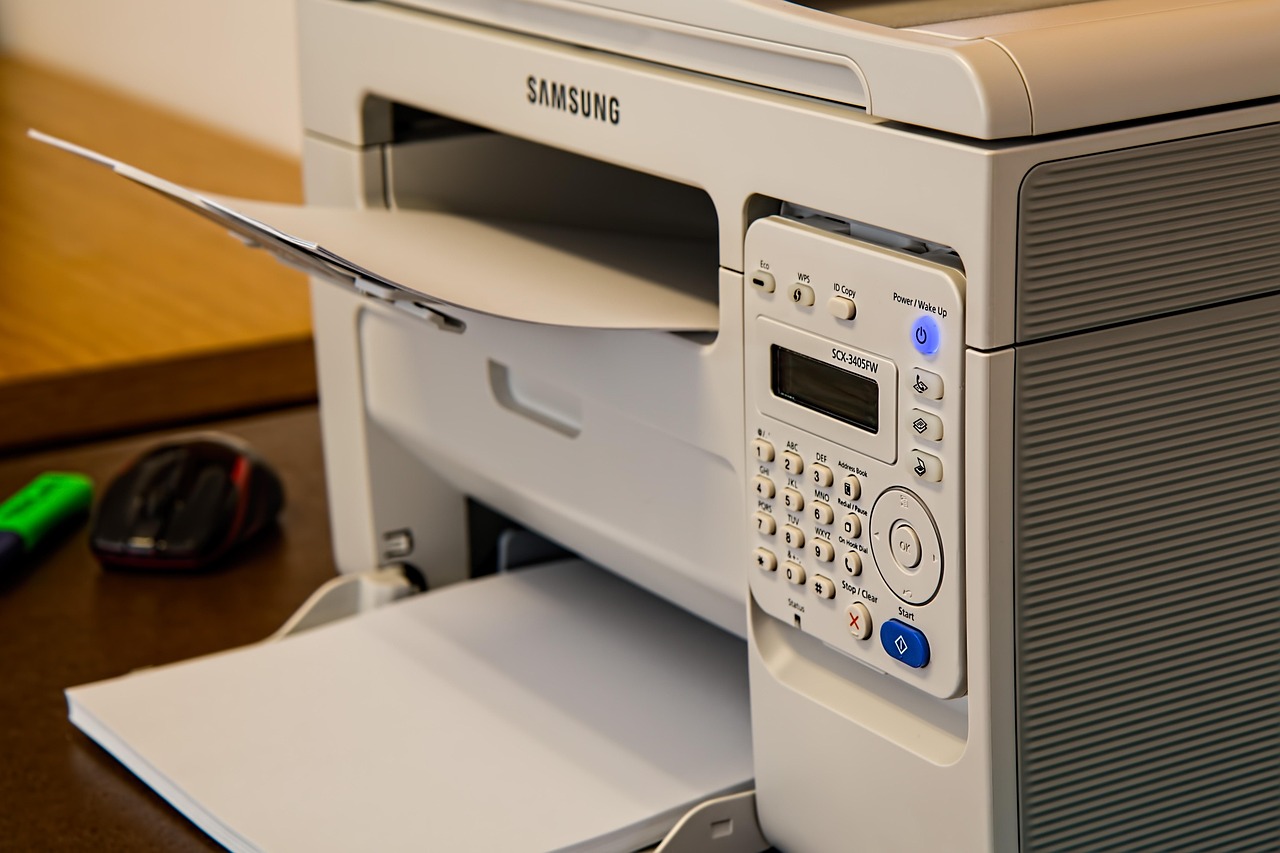

In electronics and office equipment, printer components utilizing this process achieved 6-10% weight reduction while maintaining dimensional tolerances within 30 microns and shortening the production cycle by 25%.

Thin-wall packaging also benefits. For instance, producing a butter tub with a wall thickness of only 0.38 mm, the microcellular process reduced clamping force requirements by 30-50% and injection pressure by 15-20%.

DKM SFM Microcellular Injection Molding Equipment & Case Studies

The microcellular process creates characteristic swirl marks or flow lines on the product surface. Therefore, it is generally recommended for non-cosmetic parts or components that will undergo secondary operations like painting or film lamination. It is also not suitable for products requiring high transparency.

For implementation, companies can choose to purchase a new injection molding machine with integrated MuCell functionality or retrofit existing qualified machines from brands like DKM, adding flexibility.

The key to successful application lies in the co-design of product, mold, material, and process. For example, using a hot runner system with needle valves yields better results. Selecting specially modified MuCell-grade materials also helps optimize the final foam quality and surface finish.

Choosing the Right Application for SFM Microcellular Injection Molding

DKM Microcellular Equipment List:

- Injection Molding Machines: Models from 180 tons to 4000 tons are capable of implementing the microcellular injection molding process.

- Gas Injection and Control Systems: Systems are available to handle gas flows of all magnitudes, from large to small.

- Mold Technology: Microcellular injection molds are provided by our partner, SINOMOULD.

DKM Microcellular Injection Molding Project Cases:

- Microcellular Foaming Technology for Plastic Pallets.

- Microcellular Molding of MRI and CT Scanner Components with 4mm Wall Thickness.