Home Appliance Mould

There are experienced team special for home appliance mould (such as for refrigerator, washing machine, air conditioner, and etc.) in Sino Mould, cooperats with Fagor, Simens, Hitachi, Unionaire, Unitech, Voltas…Annual turnover for the home appliance moulds is around USD12 million.

And the complete solution of high precision home appliance moulds can be offered according to customers’ ideas, from mouldflow analysis, product design optimization, mould design improvement and plastic parts production, which would ensure the smooth surface of home appliance, and perfect assembling.

We are still developing our technology in the home appliance molding to offer the better and better solutions for the home appliance moulds.

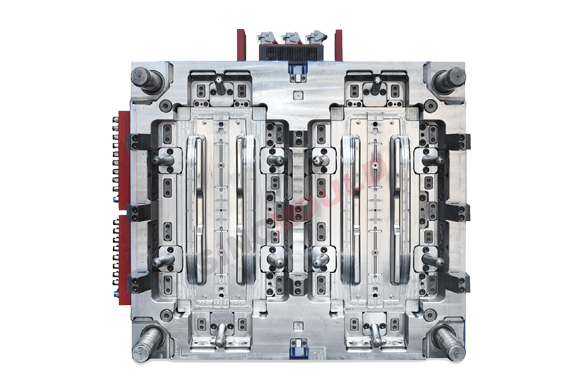

Air Conditioner Mould

Air conditioner housing Moulds and home appliance air conditioner mould, industrial center air conditioner mould and so on. Sino Mould make very well mold-flow analyzing to avoid front mask jointing line. high speed precise CNC milling, and rigorous quality controlling processing.Here below are the few features and specifications of Sino mould’s air conditioner mould:

Mould Name: Air Conditioner Mould

Product Size: 750x200x200mm

Product Description: Siemens Brand of Air conditioner

Mould Cavity: 1 cavity

Mould Size: 1100x750x850mm

Suitable Machine: Dakumar 850T

Mould Main Material: DIN 1.2738

Mould Injection System: 2 points ANOLE pin-point gate

Mould Ejection System: ejector pin and ejecting block

Mould Cycle Time: 50 Seconds

Mould Running: 800K

Delivery Time: 75 working days

Mould Features: high polishing requirement, critical injection molding process.

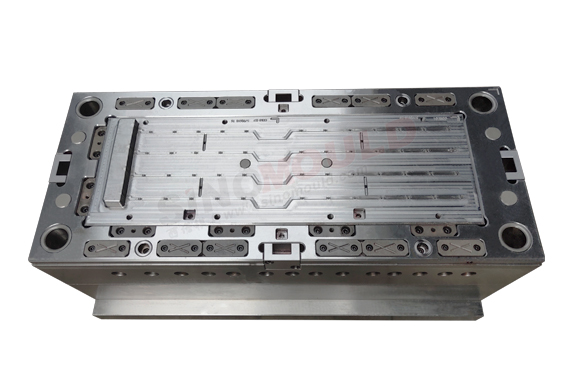

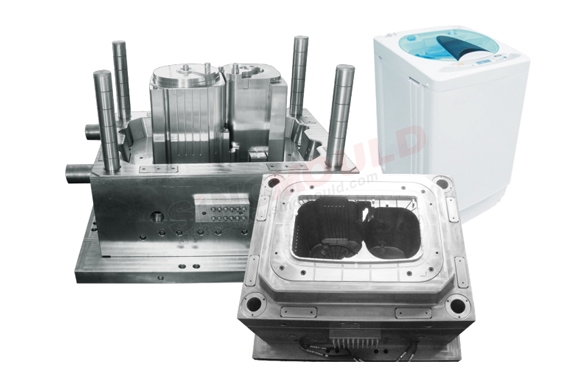

Washing Machine Mould

Sino Mould have made more than 50 sets of various washing machine mould sets, some of the washing machine mould is for 6KG capacity, some of the washing machine mould sets are for 8KG, we have many experiences in washing machine mould manufacturing.

The main advantage of Sino Mould in home appliance mould such as washing machine mould, is the surface finish and the plastic assembling effect of the washing machines. As you know all the plastic home appliance parts, specially the famous brand such as LG, SEMENS and so on, the assembling effect is extremely important for the brand. Therefore, high tooling precision is a must. To choose the most shining steel like NAK80 steel, is helping a lot in the finish the polish. And due to the material character, on high HRC, the mould still remain very high tooling capacity. Therefore, after long term running, the plastic mould is running still perfect in parting line and last shining.

Mould Name: Washing Machine Mould

Product Size: 700x400x186mm

Product Description: washing machine cover

Mould Cavity: 1 cavity

Mould Size: 1150X850X680mm

Suitable Machine: DKM 550Ton

Mould Main Material: 718H

Mould Injection System: Anole hot runner 4 tips

Mould Ejection System: ejector pin

Mould Cycle Time: 72 Seconds

Mould Running: 500K

Delivery Time: 75 working days

Mould Features: high tooling precision

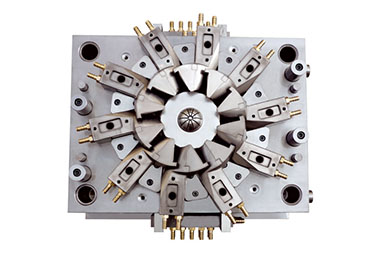

Fan Blade Mould

Sino Mould is good at various consuming electronic plastic parts mold manufacturering, such like electric box mould,switch box mould and fan mould.Sino make special design for fan blade mould, that is both automatic working but also high precision and high quality.

There are different fan mould, however, no matter which shape of plastic fan blade, SINO use the high precision tooling 5axis milling machine from DMG brand, for tooling the fan blade mould sliders. Therefore, once the finish tooling, the mold parting is shining and pefect match.

On the other hand, the injection fan blade mold must have high precision in centering of the fan with the outside frame. SINO gives special solution for the centering location, therefore, after the assembling, the plastic fan and the frame runs without any noise of testing.

In a word, duing the past years, SINO has set up a full complete quality inspection system in fan blade mould design, tooling and molding solution.

Mould Name: Fan Blade Mould

Product Size: 300x300x180mm

Product Description: Fan Blade

Mould Cavity: 1 cavity

Mould Size: 800x800x680mm

Suitable Machine: DKM-650Ton

Mould Main Material: S136

Mould Injection System: Anole Hot Runner

Mould Ejection System: Eject Plate

Mould Cycle Time: 20 Seconds

Mould Running: 1 M

Delivery Time: 60 working days

Mould Features: Multi-slider movements, high precision & balance test passed.

Water filter Mould

Sino filler mould choose DIN1.2316 stainless steel and chrome plating for mould core and cavity suitable for high polishing and long mould life.

Mould tooling in high precision to let core and all components in verticality to keep filter mould running in balance, no any off center in part when long time running.

Hot runner valve gate for easy injection and good controlling for transparency of parts, no any yellow or flow mark.

Mould Name: Water filter Mould

Product Size: dia100*250mm

Product Description: Water filter

Mould Cavity: 1cavity

Mould Size: 750*620*800mm

Suitable Machine: DKM550SV

Mould Main Material: DIN1.2316

Mould Injection System: 1 tips hot runner

Mould Ejection System: Stripper eject system

Mould Cycle Time: 35 Seconds

Mould Running: 500K (5 to 6 times more than normal)

Delivery Time: 75 working days

Mould Features: