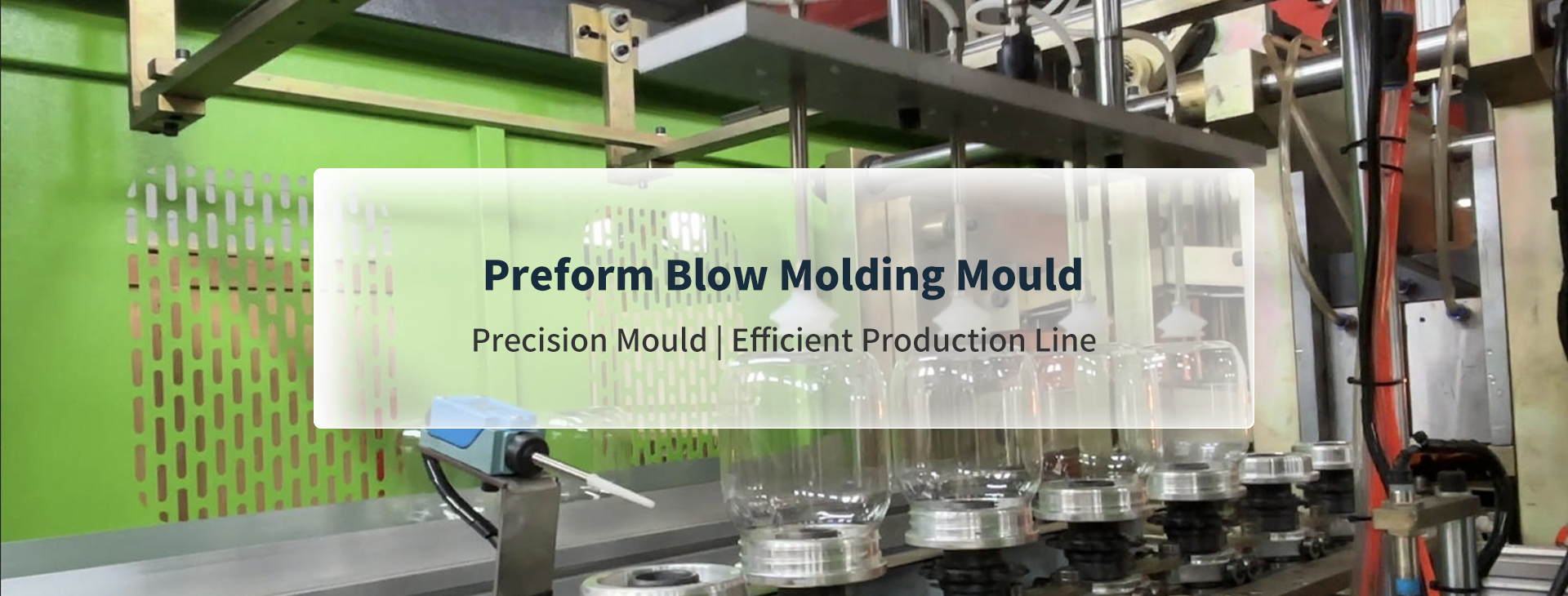

Bottle Preform Blow Molding Mould

The production of a perfect PET bottle begins with a perfect preform. The preform blow mould is the essential component that defines this first, critical stage of manufacturing. DKM’s engineering excellence ensures that every bottle preform blow molding mould we produce is optimized for precision, speed, and longevity.

Precision Engineering in Every Preform Blow Mould

Our preform blow moulds are the result of sophisticated design and rigorous precision machining. We focus on achieving perfect cavity dimensions and impeccable surface finishes to ensure each preform has consistent wall thickness and superior optical clarity. This foundational precision directly translates into better material distribution during the blow molding stage, resulting in stronger, more reliable bottles with optimal performance characteristics.

Durability and Performance of DKM Preform Moulds

Constructed from premium-grade, corrosion-resistant steels and subjected to advanced heat treatment processes, DKM bottle preform blow molding moulds are built for endurance. They are engineered to withstand the high pressures and thermal cycling of continuous operation, ensuring minimal downtime and lower long-term cost of ownership. Our robust design guarantees sustained high performance over millions of cycles.

The Core of Efficiency: Advanced Cooling Systems

The efficiency of a preform blow mould is largely determined by its cooling system. DKM integrates scientifically designed, high-efficiency cooling channels directly into our moulds. This optimized thermal management ensures rapid and uniform heat extraction from the injected PET, significantly reducing cycle times while preventing defects. This technology is key to maximizing your production output and energy efficiency.