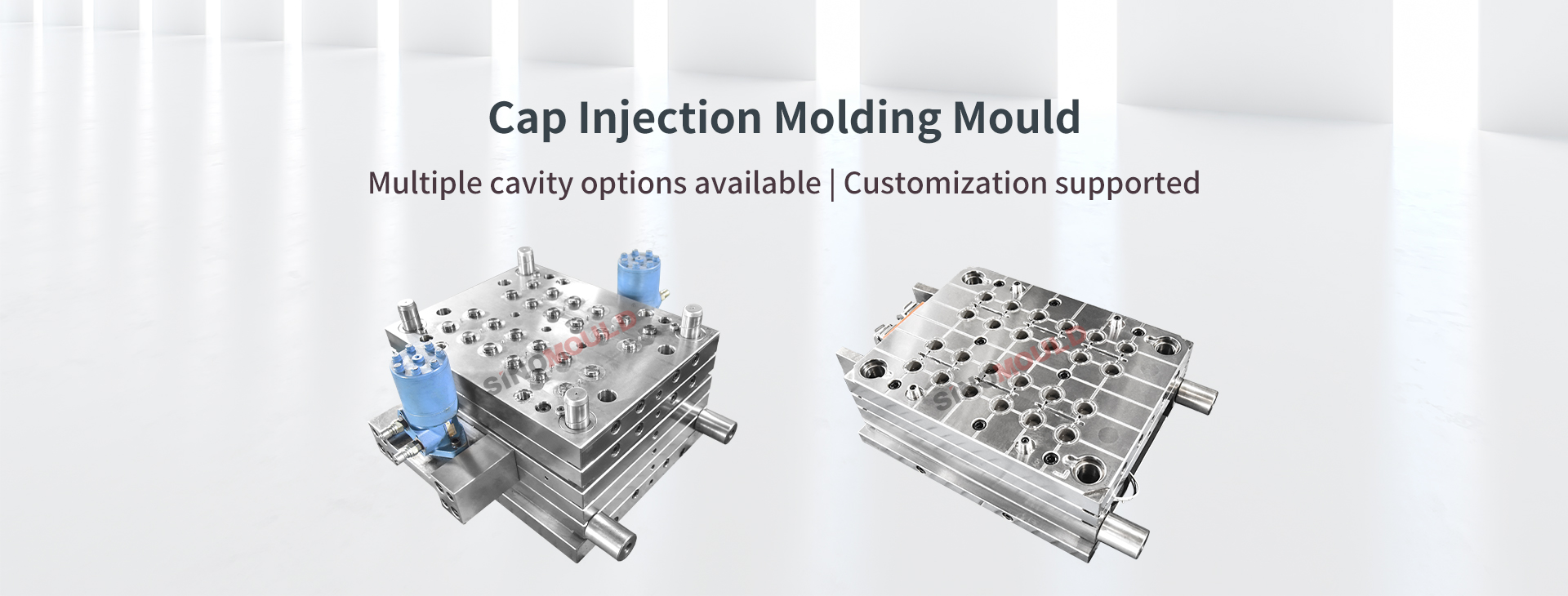

Cap Injection Molding Mould

In the packaging industry, a precision cap injection mold is not only crucial for product sealing but also a direct reflection of brand image. SINO MOULD specializes in providing global clients with high-performance cap injection mold solutions. We produce a wide range of bottle cap molds, including water bottle cap molds and beverage cap molds, covering everything from everyday beverage caps to specialized container lids. Leveraging expert craftsmanship and innovative technology, we ensure that every cap achieves exceptional dimensional accuracy and superior surface quality.

As experts in mold manufacturing, we have a deep understanding of the structural complexity and unique requirements of cap molds. For instance, for caps featuring threads and internal ribs, SINO MOULD employs multi-cavity mold designs and internal slider mechanisms to ensure precise thread formation, smooth ejection, and flawless external surfaces. For more structurally complex flip-top caps, we utilize multi-plate splitting structures and delayed ejection mechanisms to handle multiple internal ribs, enabling forced demolding and ensuring minimal gap formation after the cap is closed.

Choosing SINO MOULD means you benefit from:

- High-Precision Mold Design: Ensures stable dimensions, clear threads, and tight fits for each cap, significantly enhancing product sealing and user experience.

- Excellent Production Efficiency: Maximizes output per injection cycle and reduces unit cost through multi-cavity molds (e.g., one-module eight-cavity or higher) and optimized runner design.

- Wide Compatibility for Materials and Cap Types: Our molds are suitable for various plastic materials like PP, PE, PVC, ABS, offering flexibility to meet different cap specifications and functional requirements.

- Comprehensive Technical Support: We provide full-process technical support from mold design and production to debugging, ensuring your operations are efficient and smooth.

Main High Technologies of Cap Injection Molding Mould

We are committed to integrating advanced mold technology with practical production needs to create long-term value for our clients.

A. Efficient Gating and Hot Runner Systems of Cap Injection Molding Mould

In hot runner system design, we apply three-plate pin-point gates or hot runner systems according to cap characteristics. Hot runner systems effectively avoid surface condensation in the runner, reduce injection pressure loss, save raw materials, and lower product costs. This design is particularly important for caps with high aesthetic requirements.

B. Precision Molding Mechanisms of Cap Injection Molding Mould

In hot runner system design, we apply three-plate pin-point gates or hot runner systems according to cap characteristics. Hot runner systems effectively avoid surface condensation in the runner, reduce injection pressure loss, save raw materials, and lower product costs. This design is particularly important for caps with high aesthetic requirements.

C. Optimized Cooling of Cap Injection Molding Mould

The mold's cooling system is crucial for the injection cycle and product quality. SINO MOULD molds incorporate independent cooling circuits in key areas like cores and cavities, ensuring uniform and efficient cooling, shortening the molding cycle, reducing product warpage, and guaranteeing production stability and efficiency.

Professional Capabilities of SINO Cap Injection Molding Mould

Our professionalism is reflected in the entire mold manufacturing process, ensuring every mold delivers outstanding performance and long service life.

A. High-Standard Materials of SINO Cap Injection Molding Mould

The mold's cooling system is crucial for the injection cycle and product quality. SINO MOULD molds incorporate independent cooling circuits in key areas like cores and cavities, ensuring uniform and efficient cooling, shortening the molding cycle, reducing product warpage, and guaranteeing production stability and efficiency.

B. Quality Control of SINO Cap Injection Molding Mould

We implement a strict quality control system from design to delivery. Using CAD/CAE/CAM technologies for design and analysis, and conducting rigorous mold tests before shipment, we ensure stable and reliable mold performance and precise cap dimensions in production.

C. Support for Turnkey Projects of of SINO Cap Injection Molding Mould

SINOMOULD not only provides high-quality molds but also offers complete turnkey solutions. We can recommend or supply corresponding injection equipment (such as DKM series injection molding machines) based on your production needs, helping you quickly establish efficient, automated cap production lines.

Perfect Caps of SINO Cap Injection Molding Mould

In a highly competitive market, a high-quality cap originates from a high-precision mold. With profound technical expertise, a rigorous manufacturing attitude, and continuous innovation, SINO MOULD is your trusted partner.

Invest in Professionalism, Reap Lasting Value:

Facing increasingly complex cap designs and cost pressures, choosing a partner capable of providing mature, stable, and complete mold solutions is crucial. SINO MOULD is dedicated to safeguarding your cap production through our specialized technology and extensive experience.

Partner with SINOMOULD for a Win-Win Future:

Let’s start from an exquisite cap and collaboratively shape your brand’s image of excellence!