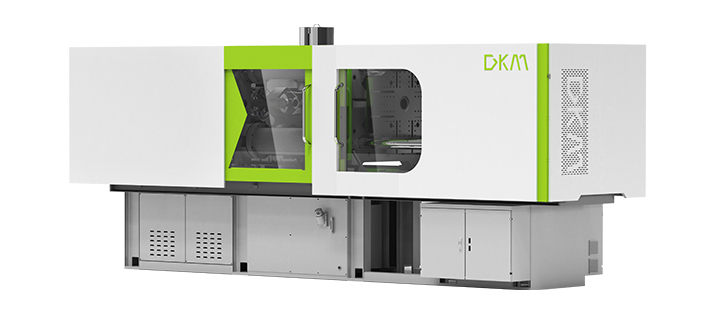

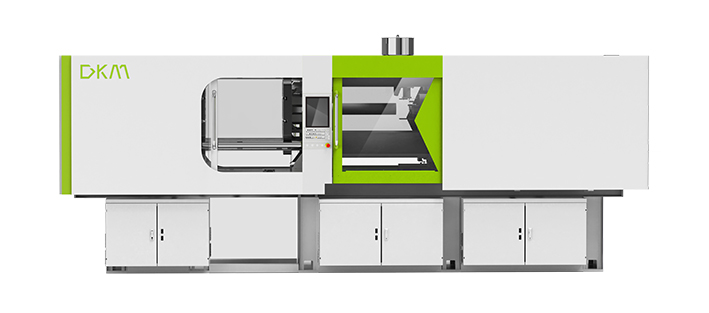

Medical Injection Molding Machine

Accuracy and cleanliness are crucial in the quickly developing field of medical technology. Introducing the MX series -DKM, an advanced plastic injection molding machine specially designed for medical applications. This advanced machine is transforming the manufacturing process of medical devices and components. The 250Ton-DKM offers great accuracy, speed, and dependability thanks to its cutting-edge technology and distinctive features. By creating high-quality, secure, and reasonably priced medical solutions, it satisfies the expanding demands of the healthcare industry.

Clamping Force

1300-4500kN

Structure

Two-Platen

Machine Drive

Machine Drive Hybrid

- Medical Injection Molding Machine 250Ton-DKM

The 250Ton-DKM Medical Injection Molding Machine is a technologically advanced and highly efficient plastic injection molding machine specifically designed for medical applications.

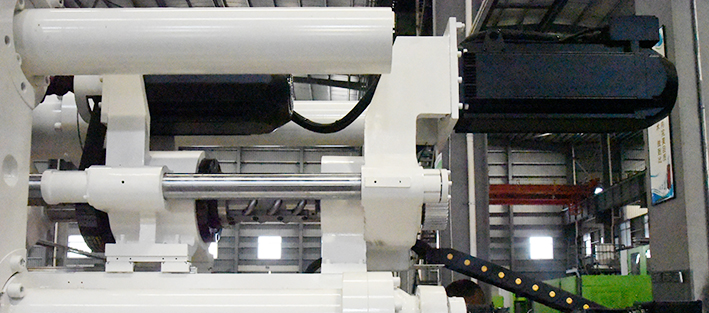

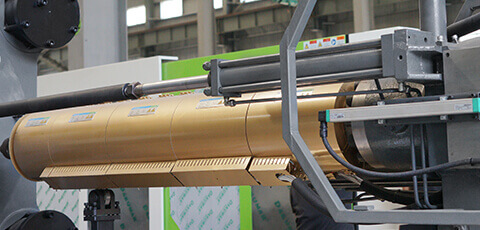

Injection system servo full electric injection, high precision screw motion control, so that the injection displacement is very precise, high speed injection so that the molding product stress balance without deformation, is the only choice for precision medical parts injection.

Besides meeting the stringent cleanliness requirements of medical applications. It also features fast injection speeds and a short cycle time, maximizing productivity and reducing manufacturing time.

Safety is a priority, as the machine includes comprehensive safety features such as emergency stop buttons, safety doors, and automatic fault detection systems. It is compatible with a wide range of molds, providing flexibility in manufacturing different medical devices and components.

Additionally, the machine is designed to be energy-efficient, incorporating energy-saving technologies for reduced power consumption, cost savings, and environmental sustainability.

- Wide range of tonnage options available, from 130 tons to 4000 tons

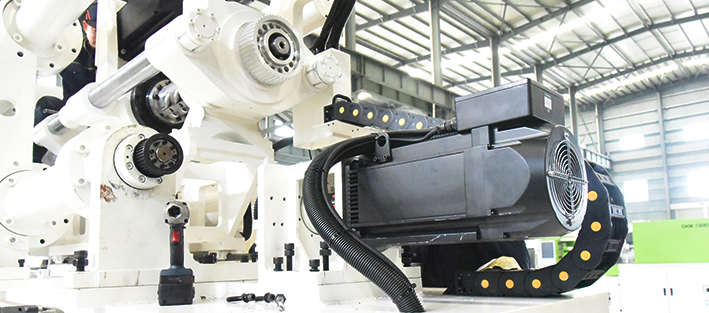

- Utilizes advanced servo motor technology for precise and efficient operation

- High-speed injection for improved productivity

- Energy-efficient design reduces power consumption

- Exceptional precision and repeatability for consistent quality

- Versatile machine capable of handling various types of plastics

- Robust construction for durability and longevity

- User-friendly interface for easy operation and monitoring

- Advanced control system for precise parameter adjustment

- Safety features to ensure operator protection

- Optional customization and configuration to meet specific production requirements

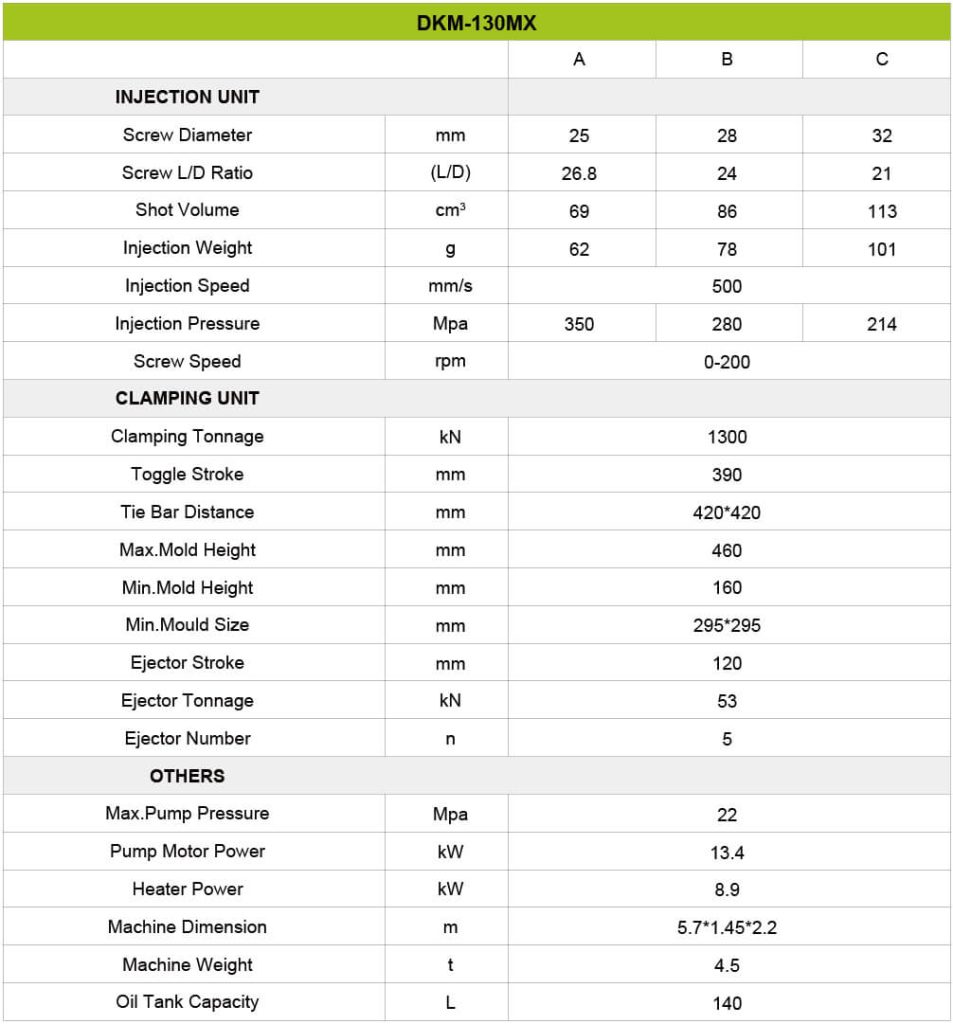

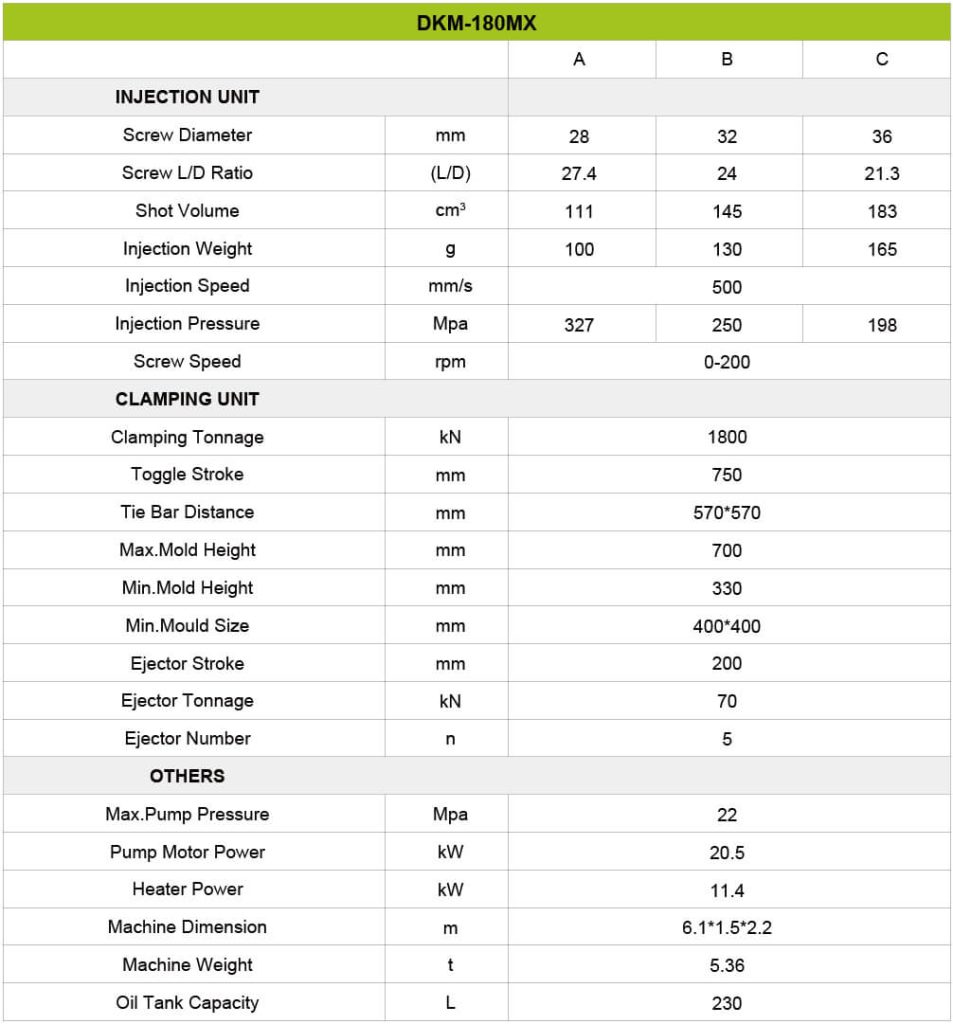

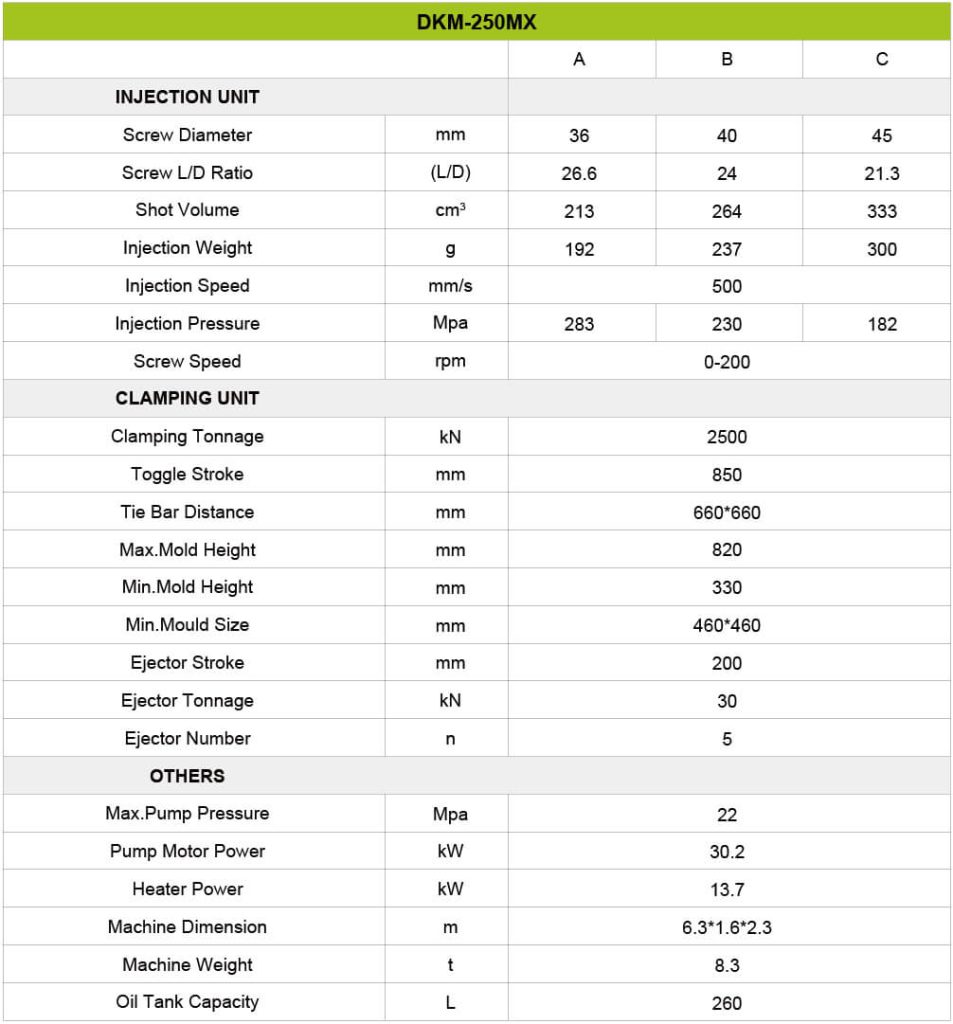

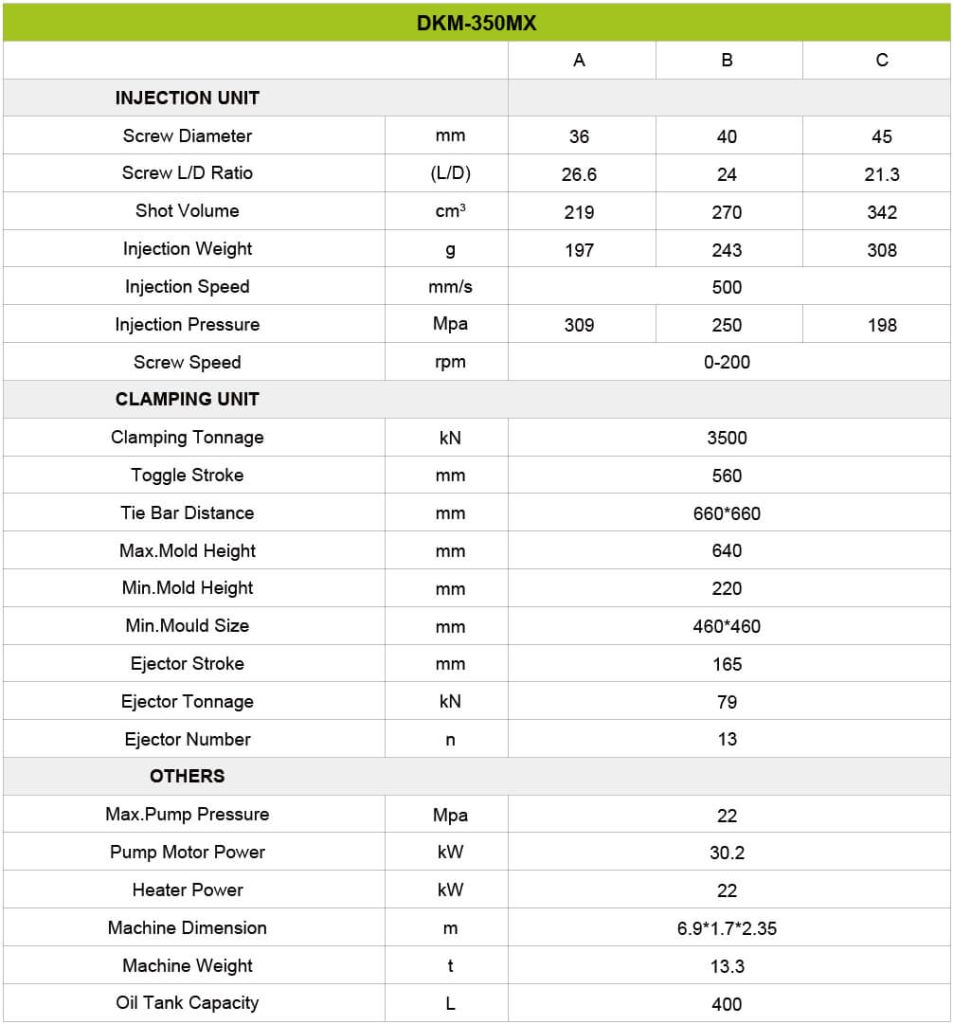

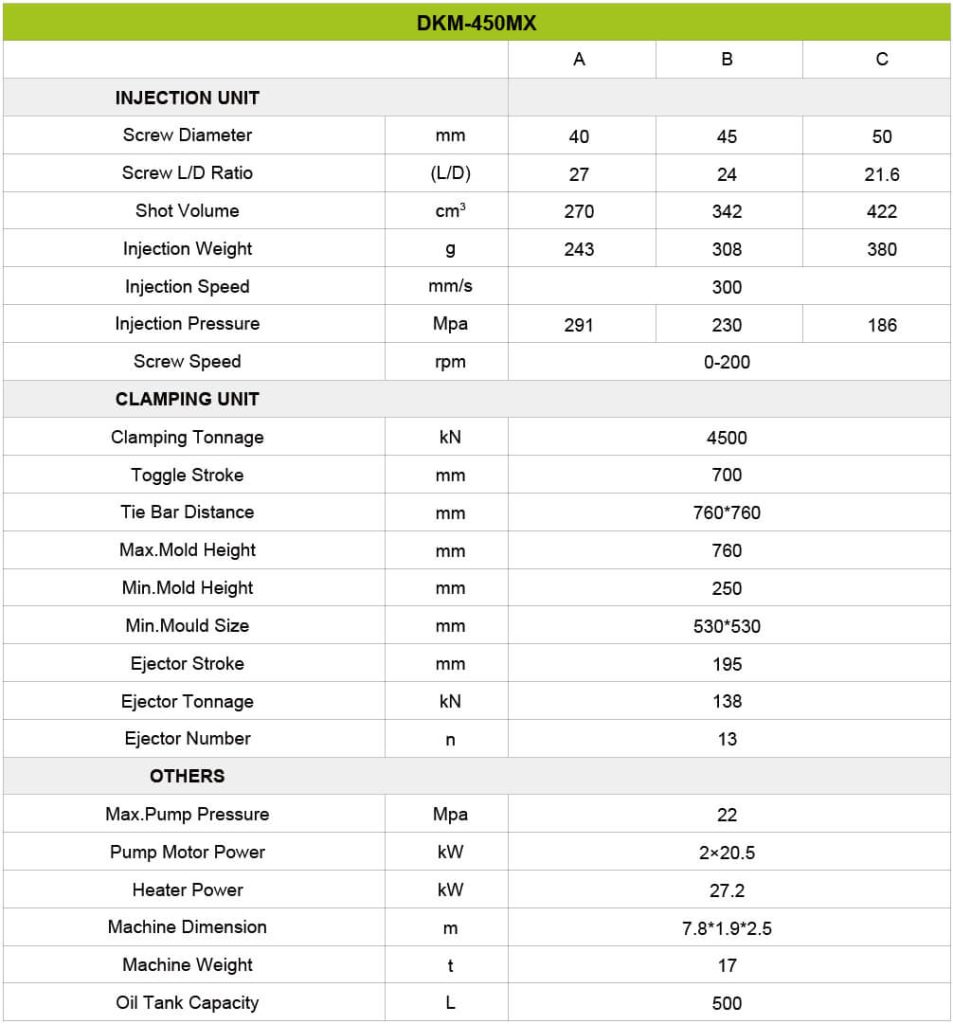

- MX Injection Molding Machine Specification

- Medical Injection Molding Machine 250Ton-DKM in Operation

When the medical injection molding machine 250Ton-DKM is in operation, it showcases its remarkable capabilities and precision. The process begins with the loading of high-quality plastic pellets into the machine’s hopper. The pellets are then fed into the injection unit, where they are heated and melted under controlled temperatures. The advanced control system ensures precise control over the injection speed, pressure, and temperature, allowing for accurate replication of the mold. Once the plastic is in a molten state, it is injected into the mold cavity with exceptional speed and precision.

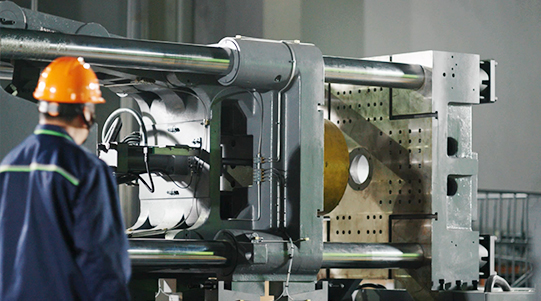

The clamping force of 250 tons holds the mold securely in place, ensuring that the molten plastic takes the desired shape. As the plastic cools and solidifies, the mold is opened, and the newly formed medical component or device is ejected.

Throughout the entire process, the machine’s servo motor technology ensures precise and repeatable movements, resulting in consistent and high-quality output. The 250Ton-DKM operates with efficiency, offering fast injection speeds and a short cycle time, maximizing productivity. Its comprehensive safety features protect operators and maintain a secure working environment.

Overall, the 250Ton-DKM in operation exemplifies its ability to manufacture intricate medical parts with exceptional precision, speed, and reliability, meeting the stringent requirements of the healthcare industry.

- Advantages of Choosing Medical Injection Molding Machine 250Ton-DKM:

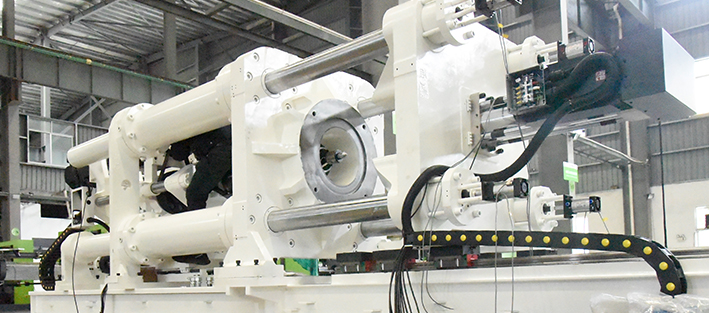

Clean molding MX injection molding machine is a new upgrade of EH medical special machine, optimize the mold clamping system, improve the clamping accuracy, further meet the high precision, high stability, high clean production needs of medical equipment, to meet the high requirements of dust-free oil free medical products.

The 250Ton-DKM medical injection molding machine offers exceptional precision in molding medical components and devices, ensuring accurate replication of molds and consistent production of high-quality parts.

With its fast injection speeds and short cycle time, the machine maximizes productivity and reduces manufacturing time, allowing for efficient production of medical products.

The machine is compatible with a wide range of molds, accommodating various sizes and designs. This versatility enables the manufacturing of diverse medical components and devices to meet specific requirements.

The 250Ton-DKM is equipped with an advanced control system that provides precise control over injection parameters such as speed, pressure, and temperature. This ensures optimal molding conditions and improves overall product quality.

The machine incorporates comprehensive safety features, including emergency stop buttons, safety doors, and automatic fault detection systems. These features prioritize operator safety and maintain a secure working environment.

Designed to be energy-efficient, the 250Ton-DKM utilizes energy-saving technologies such as servo motor control and optimized hydraulic systems. This reduces power consumption, resulting in cost savings and environmental sustainability.

With a clamping force of 250 tons, the machine securely holds the mold during the injection process, preventing any deformation or misalignment. This robust clamping force contributes to the production of precise and consistent medical parts.

The 250Ton-DKM is built with reliable components and advanced technology, ensuring consistent and reliable performance over extended periods. This reliability minimizes downtime and improves overall production efficiency.

- What You Need to Know About Medical Injection Molding Machine 250Ton-DKM

DKM One Stop Solution

When working with a Servo Motor Injection Molding Machine (80Ton-4000Ton), there are several key aspects you should be aware of:

High Injection Speed:

The machine is equipped with a high-speed plastic injection molding machine system, enabling rapid and efficient injection of molten plastic into the mold cavity. This results in faster production cycles and increased productivity.

Precision and Clean Molding:

The 250Ton-DKM ensures precise and clean molding of medical components and devices. Its advanced control system allows for accurate control over injection parameters, resulting in precise replication of molds and high-quality output.

Molding Stability:

With its robust construction and advanced technology, the machine offers excellent molding stability. It minimizes fluctuations in the injection process, ensuring consistent and reliable production of medical parts.

Low Defective Rate:

The precise control over the injection parameters, combined with the machine’s stability, helps to minimize the defective rate during the molding process. This leads to higher quality output and reduced waste.

Clamping Force:

The machine’s clamping force of 250 tons provides a strong and secure hold on the mold, preventing any shifting or deformations during the injection process. This ensures precise and accurate molding of medical components.

Ready European Standard Connector for Robot:

The 250Ton-DKM comes equipped with a ready European standard connector for robot integration. This allows for seamless automation and improved efficiency in the production process.

Why choose Dakumar for buying medical injection molding machine 250Ton-DKM?

Servo Motor Injection Molding Machines are designed to handle various types of plastics, including both commodity and engineering-grade materials. This versatility allows you to cater to diverse market demands and expand your product offerings across different industries.

These machines are built with robust construction, ensuring durability and longevity. The sturdy design can withstand the demands of high-pressure injection molding operations, reducing downtime and maintenance costs.

The machine lineup covers a broad range of tonnage options.from 80 tons to 4000 tons. This versatility allows you to selectthe appropriate machine size based on your specificproduction requirements, whether you need to produce smallcomponents orlarge-scale items.

These machines utilize advanced servo motor technologywhich provides precise and efficient operation. Servo motorsoffer excellent control over the injection process, resulting inconsistent and high-quality outputs.The dynamic control andresponsiveness of servo motors enable improved precision.repeatability.and reduced waste

Servo Motor Injection Molding Machines offer hiqh-speed injection capabilities, which contribute to improved productivityFaster injection speeds help minimize cycle times, allowing youto produce more parts in less time. This increased efficiencytranslates into higher production output and reduced costs.

Servo motor technology is known for its energy efficiency.These machines optimize power consumption by adjusting themotor speed based on the required load. They use less energyas a consequence than conventiona hydraulic svstems. whichresults in financial savings and a less environmental effect.

The high precision and reproducibility of the injection moldingprocess are made possible by the precise control provided byservo motors. This is especially important for sectors that needprecise tolerances and high-quality end products. Consistentquality output minimizes rejects and rework, leading toimproved overall efficiency and customer satisfaction.

Experience and Expertise

DKM-MX has been manufacturing injection molding machines for many years, giving them extensive experience in the industry. Their team of experts possesses deep knowledge and expertise, guaranteeing high-quality products and excellent customer service

Customization Options

DKM-MX understands that different industries have unique requirements. They provide customization options, allowing their molding machines to be tailored to your specific needs. This customization ensures optimal results for your medical applications.

High-Quality Machines

DKM-MX is dedicated to producing top-quality injection molding machines. They utilize premium materials and advanced technology during the manufacturing process, resulting in machines that are reliable, precise, and durable in operation.

Wide Range of Machines

DKM-MX offers a diverse range of injection molding machines, including models specifically designed for medical applications. Their product portfolio provides various options to from, catering to different production needs and budgets.

High-Speed Injection

Servo Motor Injection Molding Machines offer hiqh-speed injection capabilities, which contribute to improved productivityFaster injection speeds help minimize cycle times, allowing youto produce more parts in less time. This increased efficiencytranslates into higher production output and reduced costs.

Comprehensive Service and Support

DKM-MX provides comprehensive service and support throughout the purchasing process and beyond. Their team offers guidance and assistance in selecting the right machine, installation, training, and ongoing technical support to ensure smooth operation.

Competitive Pricing

DKM offers competitive pricing for the DKM-DH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

Provide Complete Supporting Equipment and Service for Your Injection Molding Machine

DKM One Stop Solution

24Hours Services

Training Equipment Maintenance And System Upgrade

- Conclusion:

In conclusion, the 250Ton-DKM Molding Machine presents an excellent choice for medical device manufacturers. With its cutting-edge capabilities, accuracy, and effectiveness, this machine is ready to transform the manufacturing of medical components and devices. The extensive knowledge and proficiency of Dakumar DKM-MX in this industry, combined with their dedication to tailored solutions and customer contentment, establishes them as a dependable collaborator for all your manufacturing requirements. By choosing Medical injection molding machine, you can benefit from high-quality machines, comprehensive service and support, and a commitment to innovation and compliance. Consider DKM-MX as your trusted provider for medical injection molding machines, and embark on a journey of efficient, precise, and cost-effective manufacturing for the medical industry.