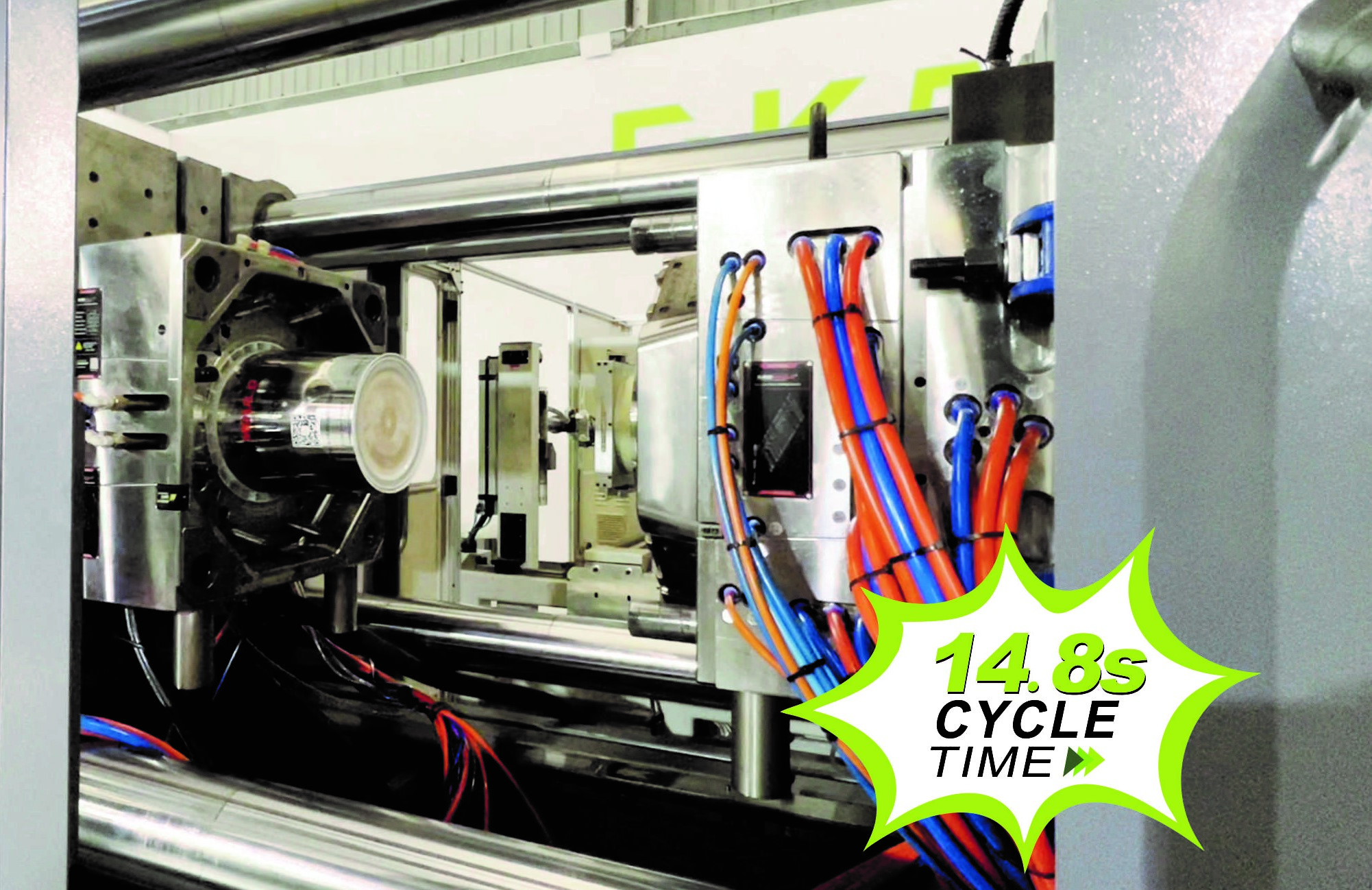

DKM-650 Victor Series: High-Speed Injection Molding Machine for Efficient 20L Paint Bucket

In the manufacturing of large-volume packaging such as 20L paint buckets, efficiency, precision, and cost control are core demands for production lines. The DKM-650Victor Series Fast