Out-Mould Preform Pick Up &.Cooling Robot

Limitations of Traditional Cooling

Cooling inside the mold accounts for over 60% of total cycle time.

Mold temperature fluctuations compromise product quality.

Inability to perform injection and cooling in parallel.

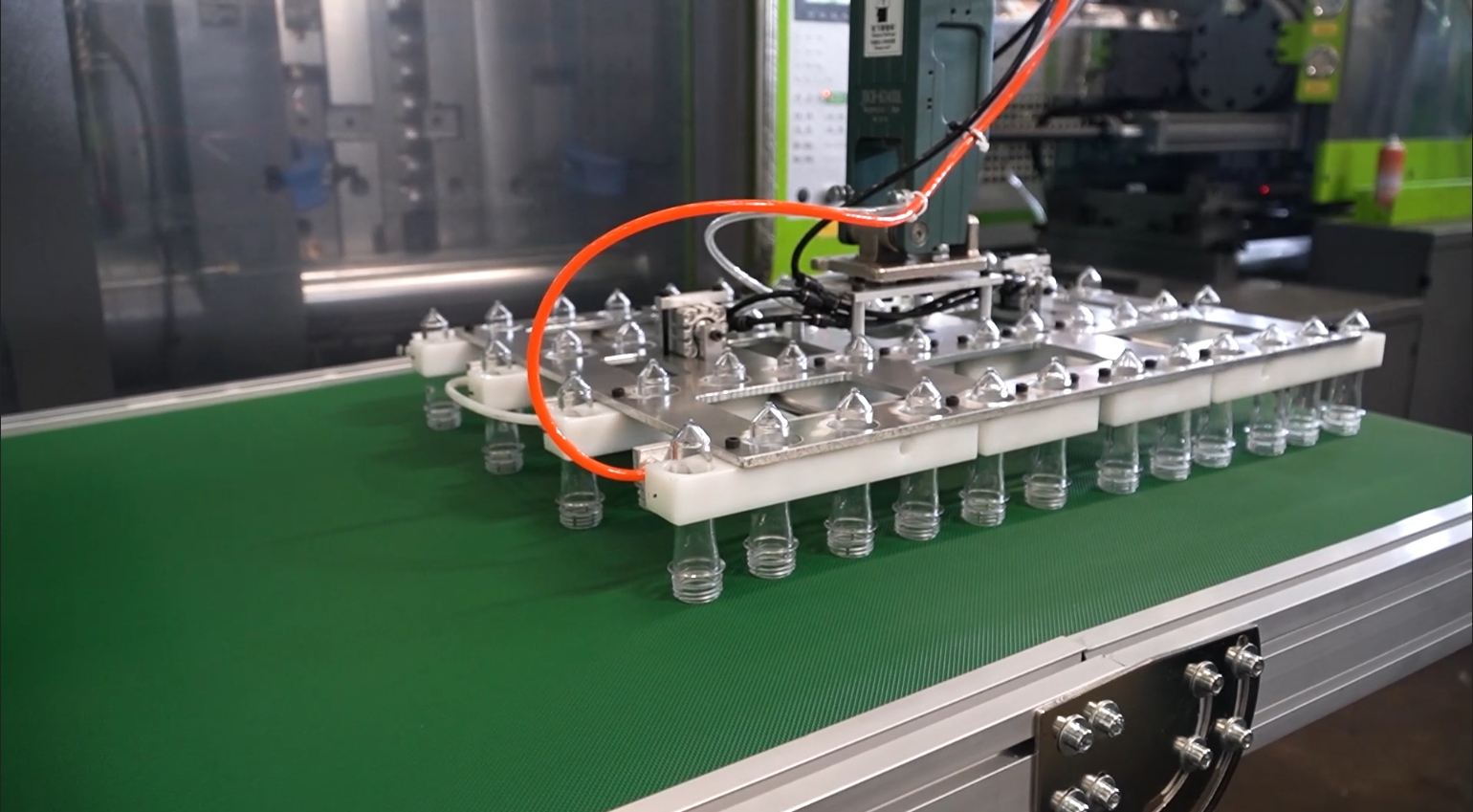

The Out-of-Mold Breakthrough

Decoupling cooling from the mold: Robots extract preforms immediately after molding.

Dedicated cooling stations enable precise temperature control.

Parallel processing: Injection and cooling occur simultaneously.

Key Advantages

Maximized Productivity

Parallel operations eliminate bottlenecks.

Higher mold utilization and output per hour.

Optimized Product Quality

Stable cooling environment ensures consistency.

Reduced internal stress improves mechanical properties.

Lower Operational Costs

Distributed energy consumption.

Extended mold life and reduced maintenance.