DKM PET Water Bottle Production Line

PET Water Bottle Production Line

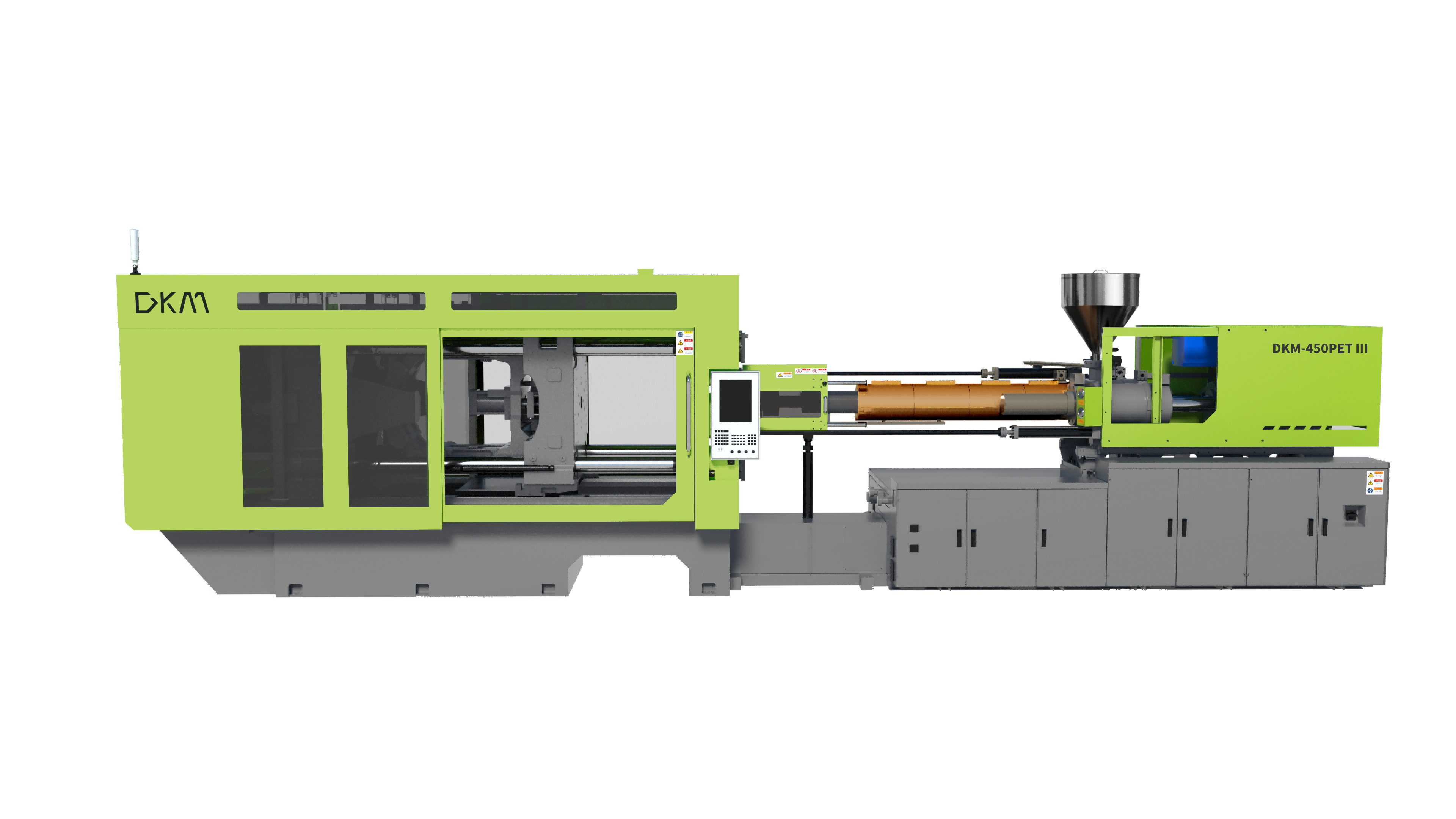

DKM offers a one-stop, fully automated PET water bottle production line solution, from PET preform molding, to water bottle blowing molding and bottle caps molding. DKM integrated water bottle production line combines high-performance PET bottle preform injection, bottle blow molding, and various auxiliary systems, specifically designed for large-scale, high-efficiency, and high-quality production of bottled water, beverages, cooking oil, and other liquid packaging. With outstanding stability, energy efficiency, and flexibility for various specifications, DKM PET Bottle production line is your reliable partner for enhancing market competitiveness.

Different from molds that specialize in preform injection, SINOMOULD’s bottle molds focus on the final container molding, dedicated to efficiently and precisely blow-molding pre-made preforms into various high-performance finished packaging bottles. We deeply understand the value of bottle design for brands, which is why in mold design, we integrate a profound understanding of material characteristics with exquisite processing techniques to ensure the produced bottles have uniform wall thickness, an attractive appearance, and a stable structure.