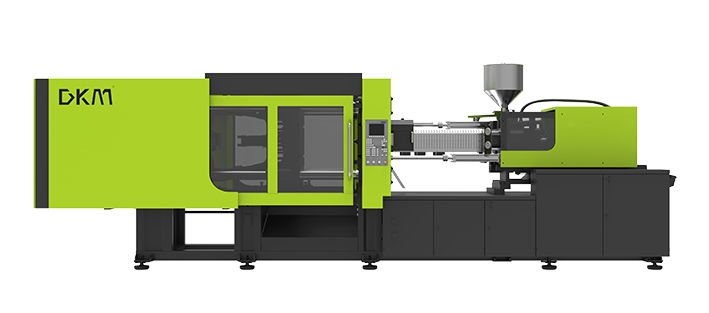

PVC Injection Molding Machine DKM-PVC SERIES

Among Dakumar’s impressive lineup of injection molding machines, one is the DKM-PVC SERIES. This series is designed to cater specifically to manufacturers engaged in the production of PVC (Polyvinyl Chloride) products. It is a versatile material widely used across various industries, including construction, automotive, packaging, and more. The DKM-PVC SERIES has been meticulously developed to offer outstanding performance, accuracy, and reliability for injection molding processes.

Clamping Force

1300-6500kN

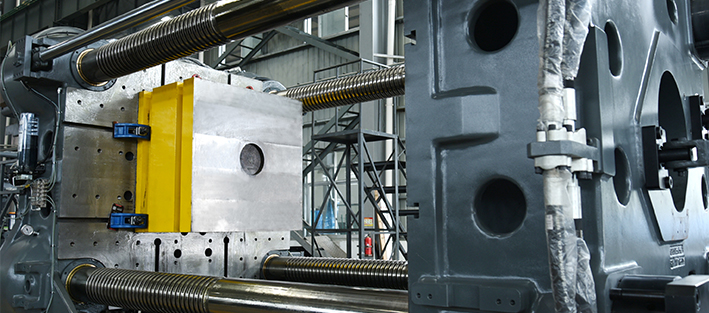

Structure

Toggle(Three-Platen)

Machine Drive

Hydraulic Servo System

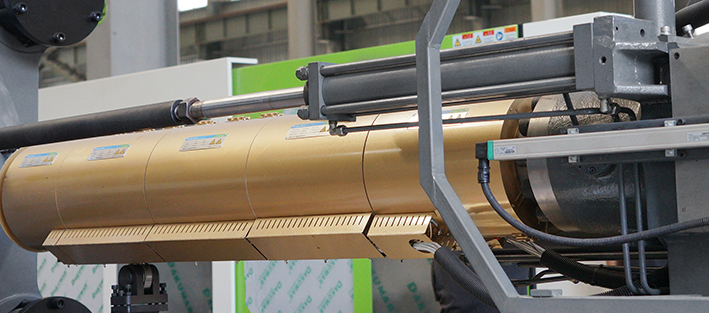

- DKM-PVC SERIES in Operations

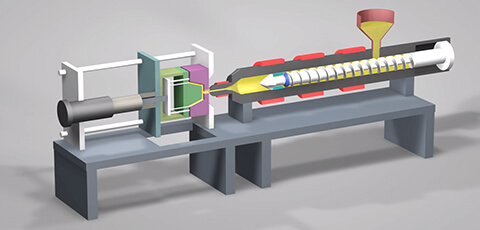

The DKM-PVC SERIES offers several features that make it a standout in the realm of molding machines. Firstly, it utilizes advanced servo motor technology, ensuring precise and consistent control over the injection process. This results in superior product quality with minimal waste. The machine also incorporates a high-response hydraulic system that enables fast injection speeds and quick mold opening and closing actions.

- Wide range of tonnage options available, from 130 tons to 4000 tons

- Utilizes advanced servo motor technology for precise and efficient operation

- High-speed injection for improved productivity

- Energy-efficient design reduces power consumption

- Exceptional precision and repeatability for consistent quality

- Versatile machine capable of handling various types of plastics

- Robust construction for durability and longevity

- User-friendly interface for easy operation and monitoring

- Advanced control system for precise parameter adjustment

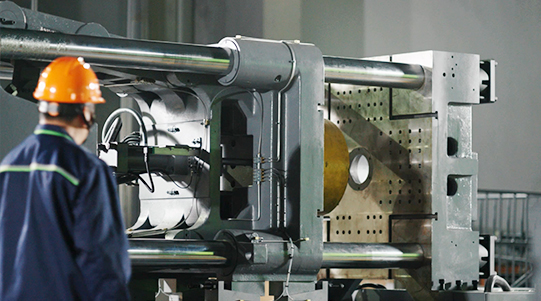

- Safety features to ensure operator protection

- Optional customization and configuration to meet specific production requirements

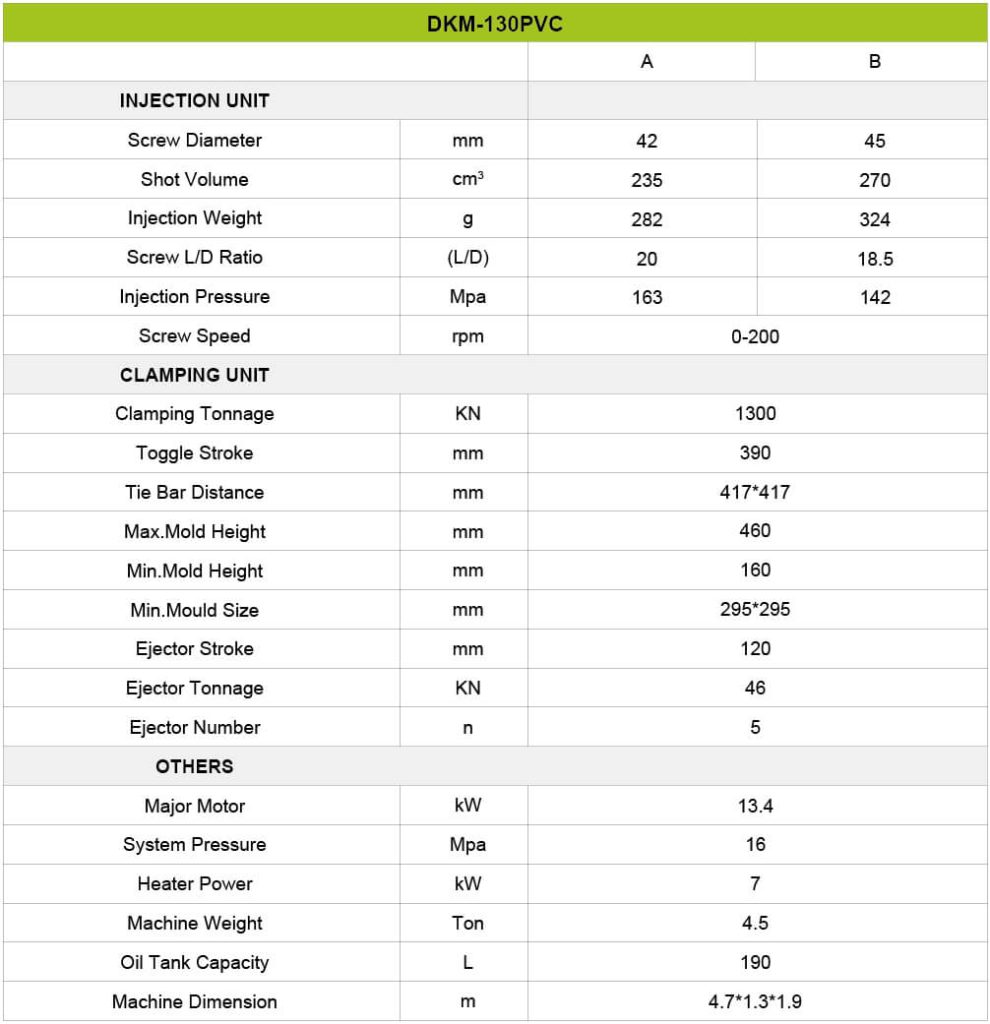

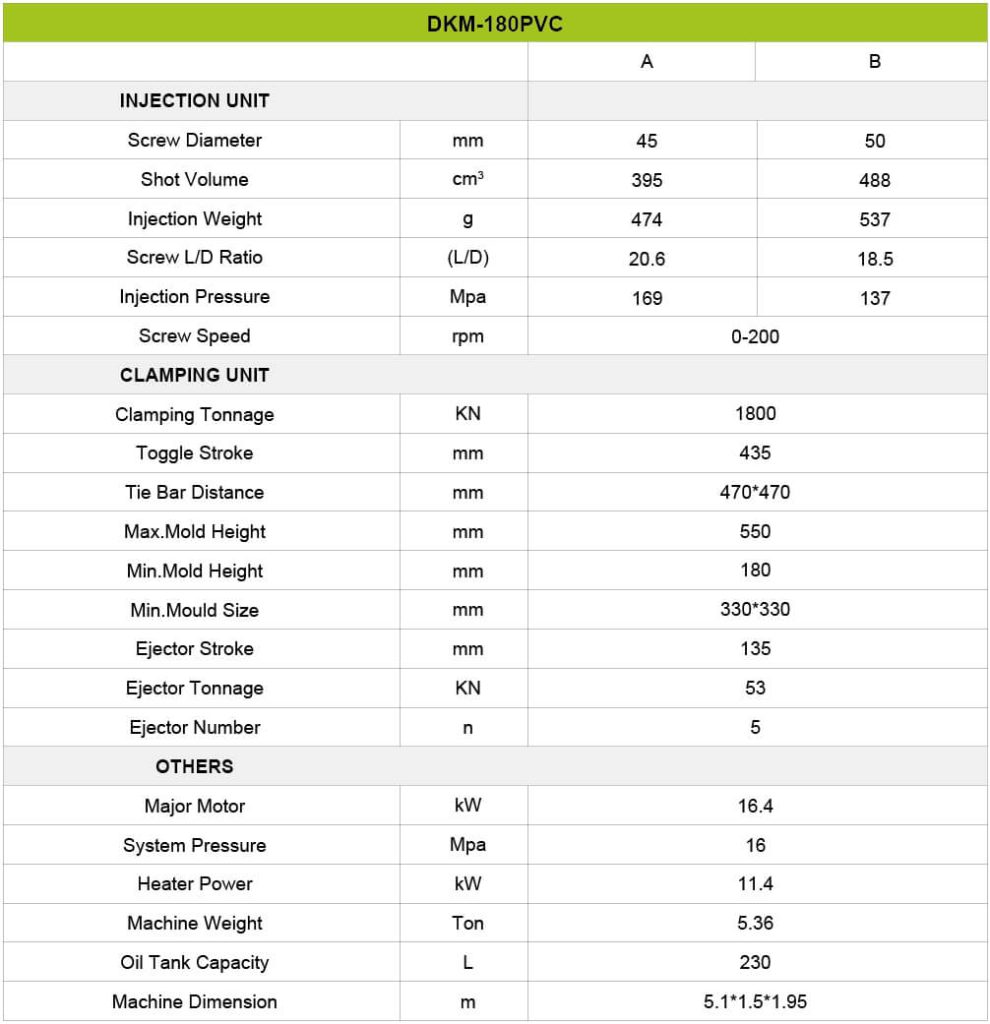

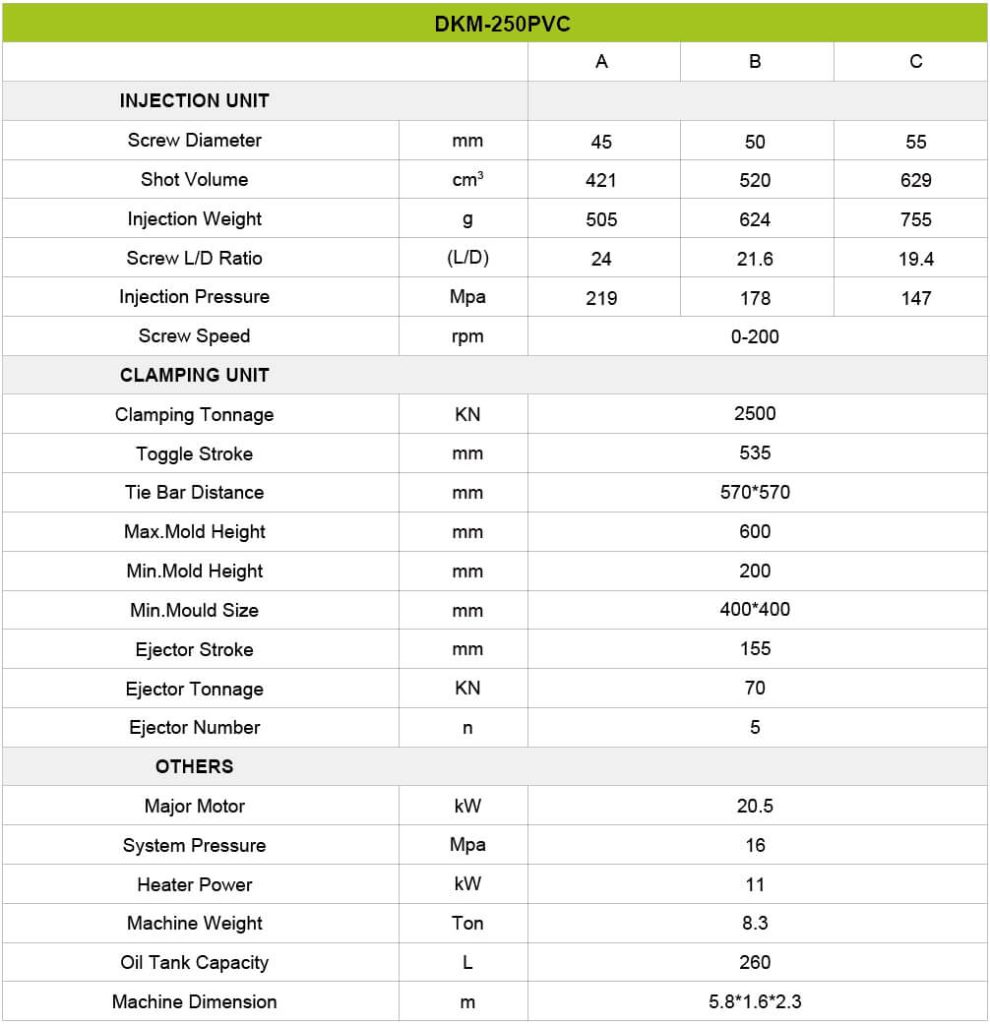

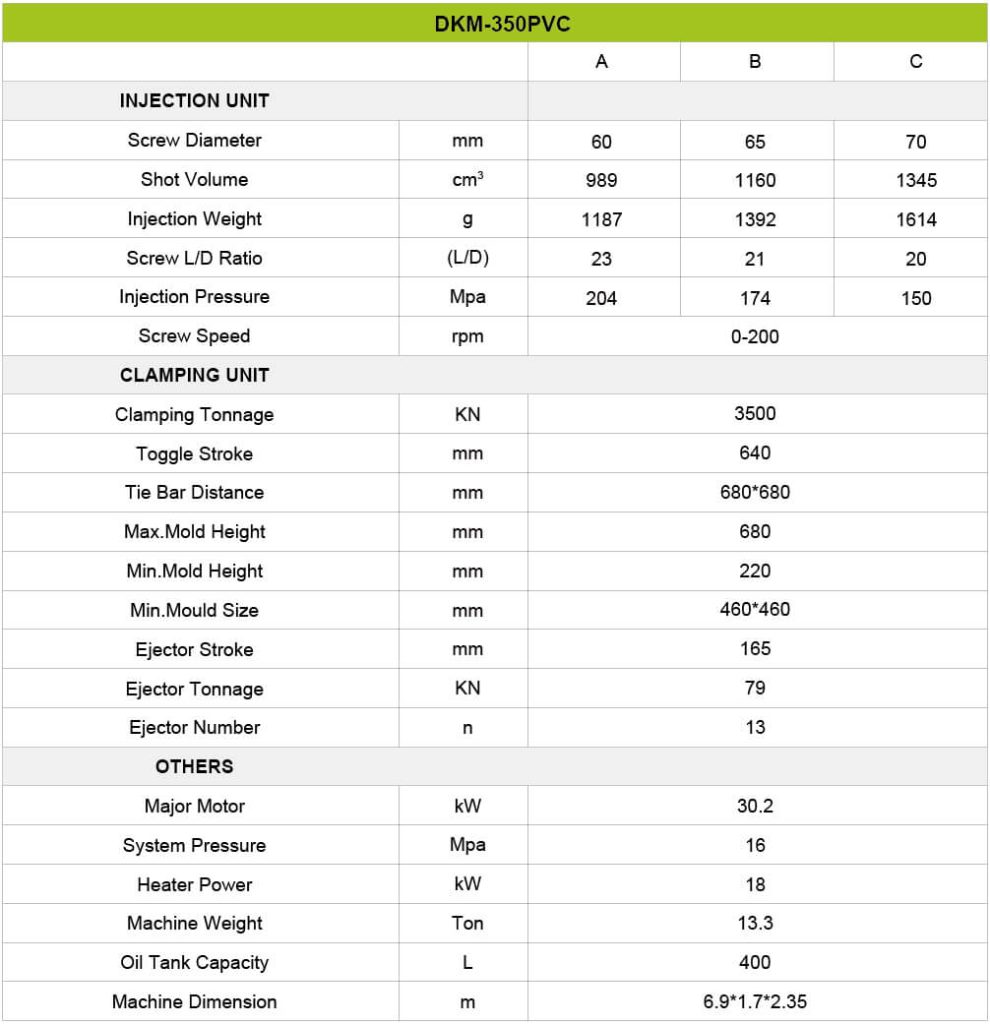

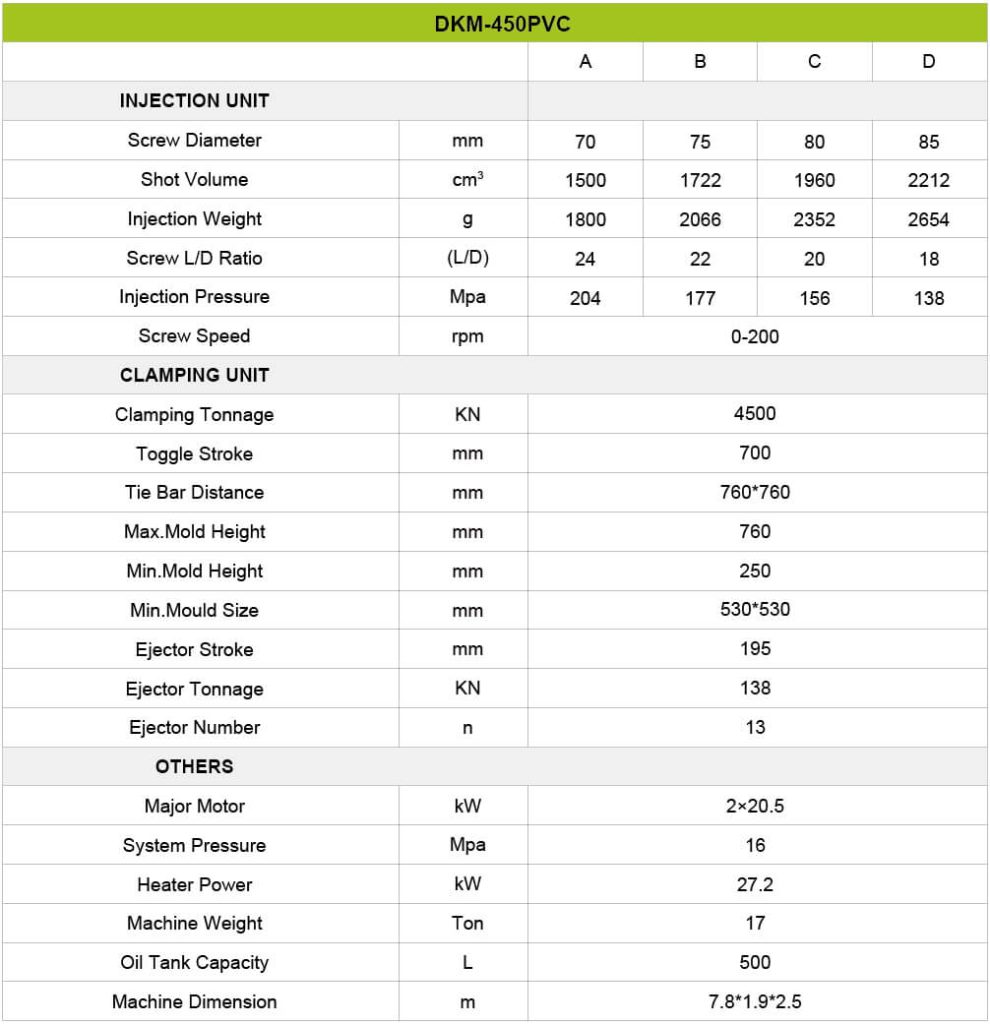

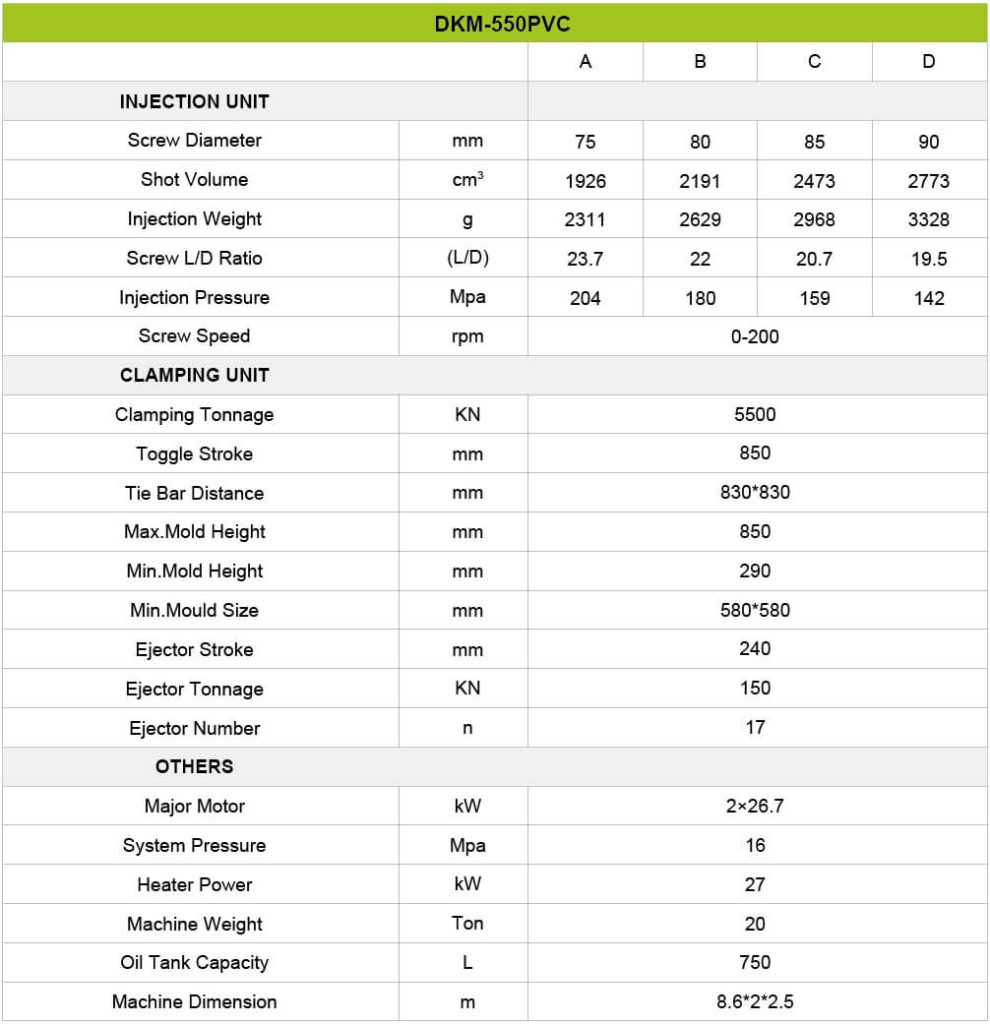

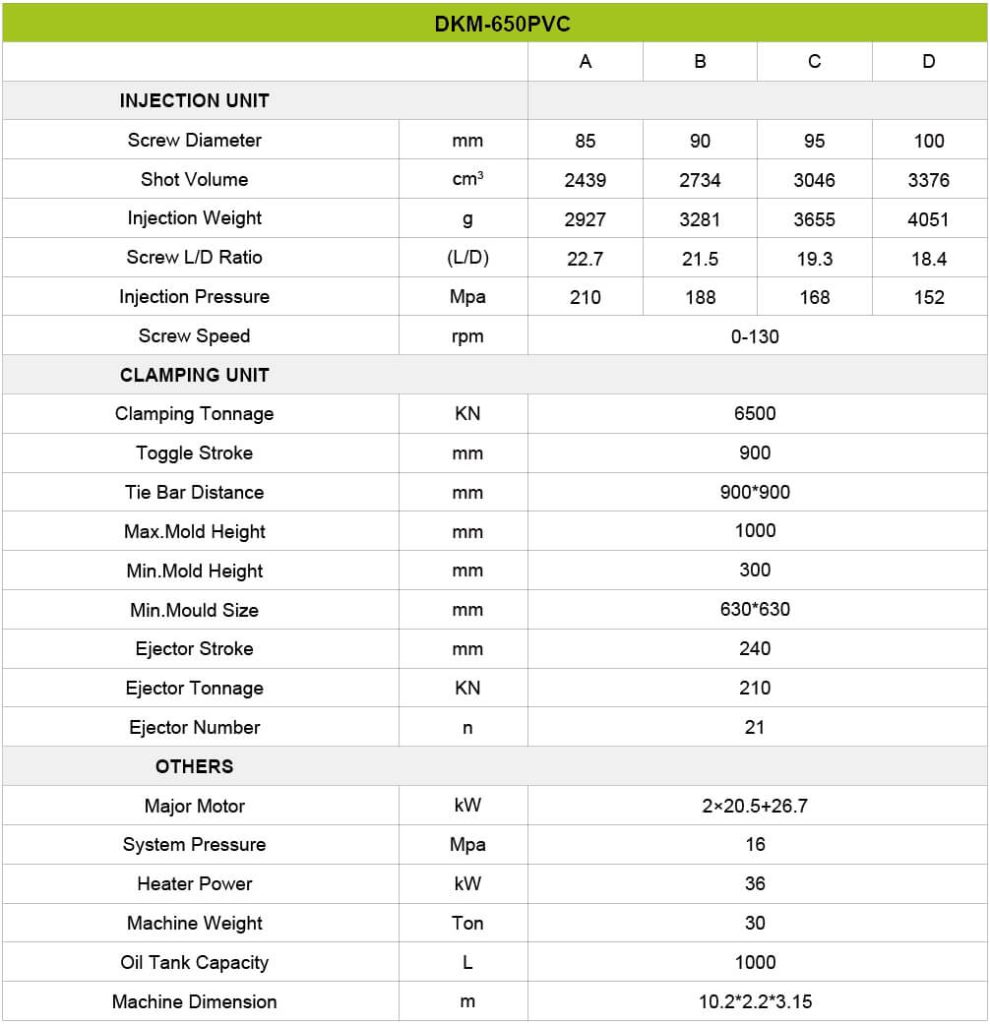

- PVC Fast Injection Molding Machine Specification

- Advantages of Using DKM-PVC SERIES:

The high precision and accuracy of the DKM-PVC SERIES ensure that molded parts consistently meet the desired specifications. This means that the machine can produce high-quality parts with minimal variation, reducing the need for rework or rejects.

The incorporation of advanced servo motor technology in the DKM-PVC SERIES significantly reduces energy consumption compared to traditional hydraulic systems. By using energy only when required, the machine optimizes power usage and lowers operating costs, making it more environmentally friendly and cost-effective.

The DKM-PVC SERIES features a high-response hydraulic system that enables fast injection speeds. This allows for shorter cycle times, meaning more parts can be produced within a given timeframe. The increased productivity leads to higher output and improved efficiency in manufacturing processes.

The SERIES is designed to mold a wide range of PVC products, catering to various industries and applications. Whether it’s automotive components, electrical fittings, or consumer goods, the machine offers versatility in terms of product design and functionality.

The intelligent control system of the DKM-PVC SERIES provides an intuitive interface that is easy for operators to understand and navigate. This simplifies the monitoring and control of the molding process, allowing operators to quickly set parameters, adjust settings, and troubleshoot any issues that may arise.

The sturdy construction of the DKM-PVC SERIES ensures stability and durability during operation. The machine is designed to withstand heavy usage and maintain consistent performance over time. Its robustness contributes to reliable operation and reduces downtime, resulting in increased productivity.

The precise control mechanisms of the machine ensure that each molded product meets the required specifications. This leads to consistent and uniform product quality, minimizing rejects and waste. The machine’s ability to consistently produce high-quality parts improves overall efficiency and reduces costs.

The prioritizes safety in its design by incorporating various safety measures. Emergency stop buttons, safety doors, and interlocks are implemented to protect operators and create a safe working environment.

Dakumar offers customization options for the DKM-PVC SERIES to meet specific production requirements and preferences. This means that the machine can be tailored to accommodate unique molding needs, such as specialized product designs, specific production volumes, or integration with existing manufacturing systems.

Dakumar provides comprehensive after-sales support for the DKM-PVC SERIES. This includes technical assistance, ensuring that customers receive guidance and troubleshooting support when needed. Spare parts availability ensures minimal downtime in case of component replacement, and maintenance services help optimize machine performance and prolong its lifespan. The reliable after-sales support

- What You Need to Know About This Machine

DKM One Stop Solution

If you are considering series here are some important factors to consider:

Advanced Servo Motor Technology:

gives the injection moulding process precise control, resulting in reliable and high-quality output. enables modifications for the best filling, cutting down on material waste and improving part quality.

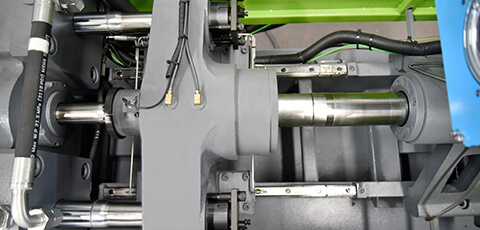

High-Response Hydraulic System:

Facilitates fast injection speeds, leading to shorter cycle times, increased productivity, and improved production output. Enhances efficiency and optimizes overall production time.

Intelligent Control System with User-Friendly Interface:

Equipped with an intuitive interface for easy parameter setting, monitoring, and adjustments. Offers live data visualization, diagnostic features, and troubleshooting guidance for streamlined operation and maintenance.

Sturdy Construction:

Ensures stability, durability, and minimized vibrations during operation, resulting in enhanced accuracy and product quality. Provides a reliable solution for large-scale manufacturing requirements.

Wide Range of PVC Applications and Product Sizes:

Accommodates various product sizes within this molding domain, making it suitable for industries such as automotive, construction, and packaging. Delivers precise and efficient molding for diverse PVC products.

Energy Efficiency and Cost Savings:

Incorporates advanced energy-saving technologies and servo motor systems to reduce power consumption and lower production costs. minimises environmental effect while promoting sustainable manufacturing.

Consistent and Uniform Product Quality:

Maintains consistent parameters throughout the molding process, resulting in uniform product quality with minimal variation. Minimizes rejections, enhances customer satisfaction, and strengthens reputation.

Safety Features and Operator Protection:

Equipped with emergency stop buttons, safety doors, and interlocks for operator protection. Includes built-in safety protocols and alarms to proactively identify and address operational hazards.

Customization Options:

Offers tailored solutions based on specific production needs, allowing customization of mold size, clamping force, injection capacity, and auxiliary equipment integration.

Reliable After-Sales Support and Maintenance Services:

Provides ongoing technical assistance, spare parts availability, and expert guidance for maintenance and troubleshooting. Ensures optimal machine performance and minimizes production disruptions.

Why Should You Consider Buying DKM-PVC Series?

Advanced Technology

The DKM-PVC Series incorporates advanced technology, ensuring manufacturers stay at the forefront of molding capabilities.

Precision and Speed

This machine offers exceptional precision and high-speed performance, allowing manufacturers to achieve accurate and efficient molding processes.

User-friendly Features

The DKM-PVC Series is designed with user-friendly features, making it easy to operate and navigate, thus enhancing overall productivity.

Enhanced Productivity

Investing in the DKM Series boosts productivity by streamlining the injection molding process and optimizing output.

Consistent Quality

With its advanced technology and precision, the Series ensures consistent and reliable quality in PVC injection molding products.

Reduced Operational Costs

By improving efficiency, minimizing waste, and optimizing resources, the DKM-PVC Series helps to reduce operational costs for manufacturers.

Reliable After-sales Support

Dakumar provides reliable after-sales support, ensuring manufacturers receive assistance and maintenance services when needed.

Customization Options

The DKM-PVC Series offers customization options, allowing manufacturers to tailor the machine to their specific requirements.

High-performance Machine

Overall, the Series is a high-performance plastic injection molding machines that delivers exceptional results for manufacturers.

Competitive Pricing

DKM offers competitive pricing for the DKM-DH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

Provide Complete Supporting Equipment and Service for Your Injection Molding Machine

DKM One Stop Solution

24Hours Services

Training Equipment Maintenance And System Upgrade

- Conclusion:

Dakumar’s DKM-PVC SERIES is a top-tier plastic injection molding machine specifically designed for PVC applications. With its advanced features, precision, and reliability, this machine offers manufacturers the capability to produce high-quality PVC products efficiently. By following the provided guidelines and considering the advantages of the SERIES, manufacturers can make an informed decision to invest in this exceptional injection molding machine, thereby gaining a competitive edge in the market.