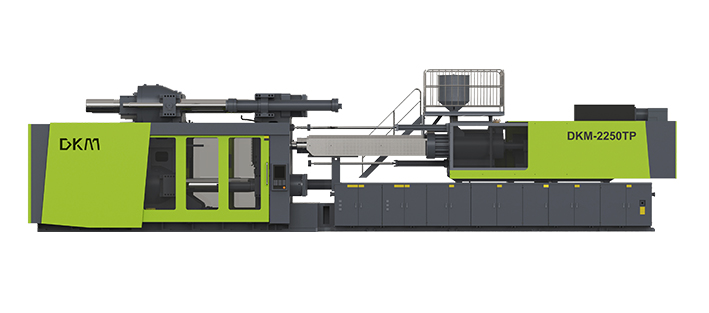

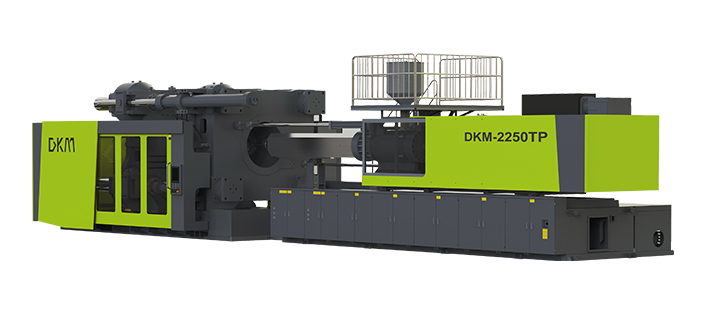

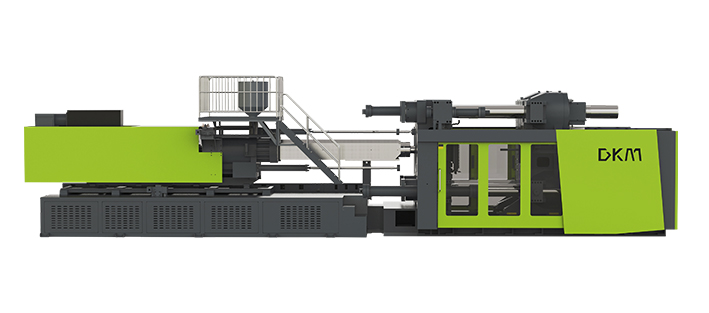

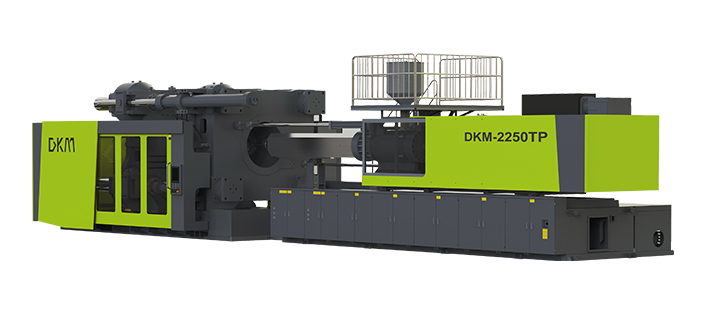

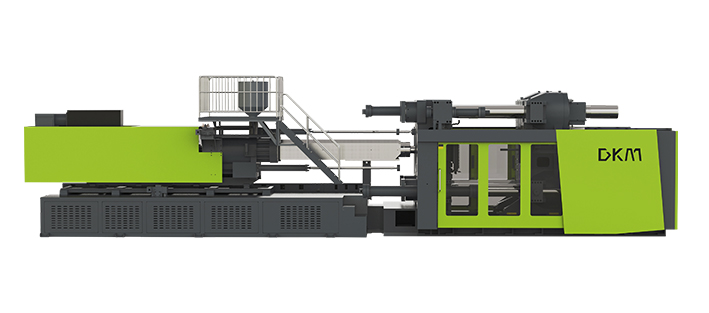

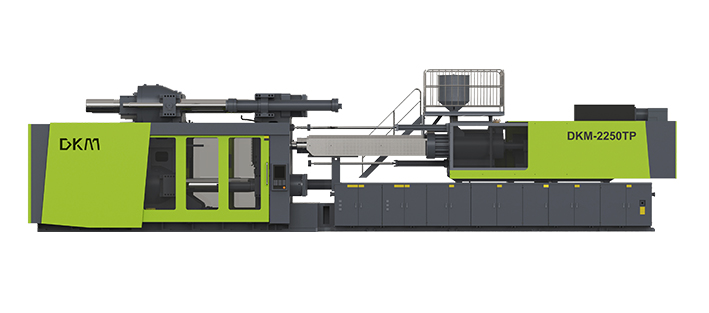

DKM-TP SERIES Two-Platen Injection Molding Machine (600Ton - 4000Ton)

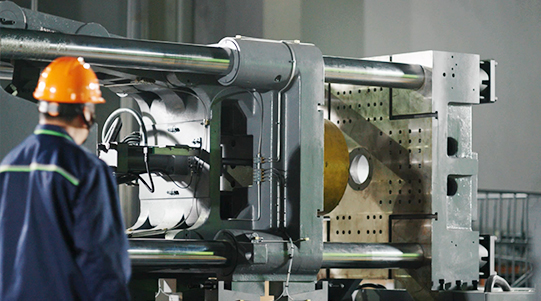

DKM injection molding machines range among the top 3 brands for two-platen injection molding machines with high precision tolerance, which is original Italian technology. With their latest innovation, the DKM-TP Series Two-Platen Injection Molding Machine, DKM is redefining precision, efficiency, and reliability in the world of plastic manufacturing. Whether you’re a seasoned industry professional or just getting started, this state-of-the-art machine is the ultimate game-changer, offering unparalleled performance and versatility. Get ready to unlock new possibilities and take your production capabilities to unprecedented heights with DKM-TP Series Two-Platen Injection Molding Machine.

Clamping Force

6000-40000kN

Structure

Two-Platen

Machine Drive

Hydraulic Servo System

- Introduction to the DKM-TP Series Two-Platen Injection molding Machine:

The DKM-TP Series Two-Platen Injection Molding Machine is an advanced and high-performance machine designed for efficient and precise injection molding processes. It incorporates innovative features and technologies to meet the demands of various industries, such as automotive, packaging, electronics, and more.

- Wide range of tonnage options available, from 130 tons to 4000 tons

- Utilizes advanced servo motor technology for precise and efficient operation

- High-speed injection for improved productivity

- Energy-efficient design reduces power consumption

- Exceptional precision and repeatability for consistent quality

- Versatile machine capable of handling various types of plastics

- Robust construction for durability and longevity

- User-friendly interface for easy operation and monitoring

- Advanced control system for precise parameter adjustment

- Safety features to ensure operator protection

- Optional customization and configuration to meet specific production requirements

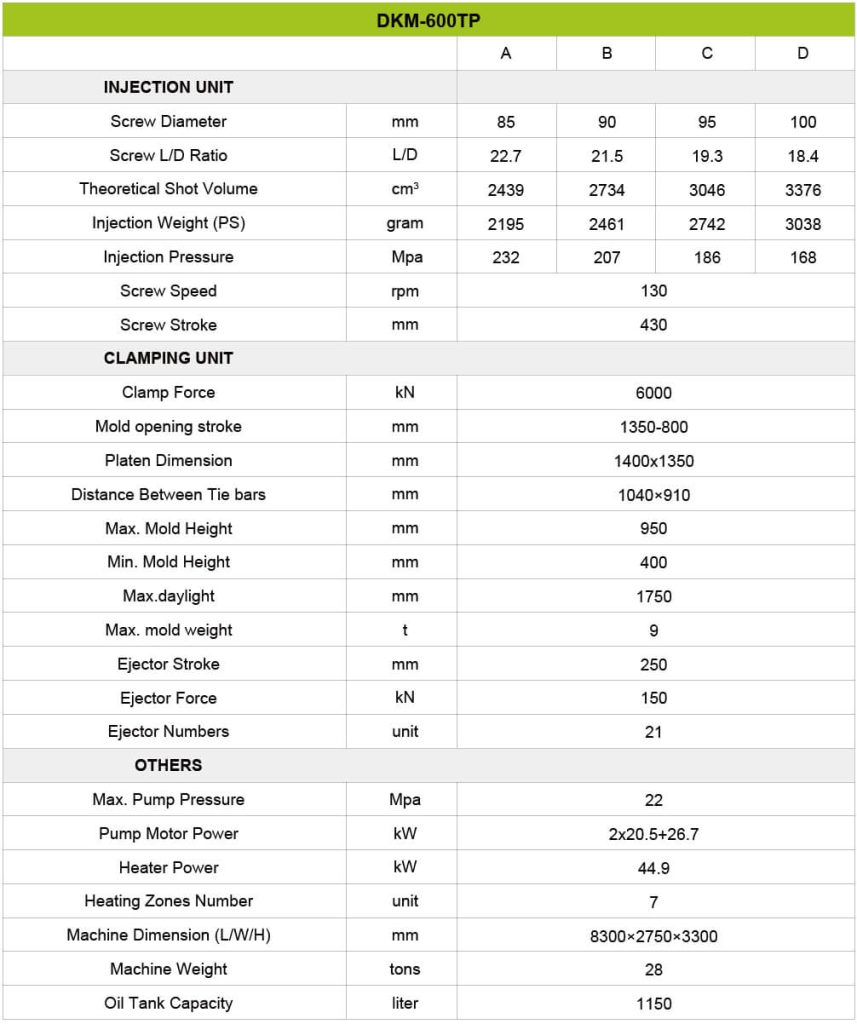

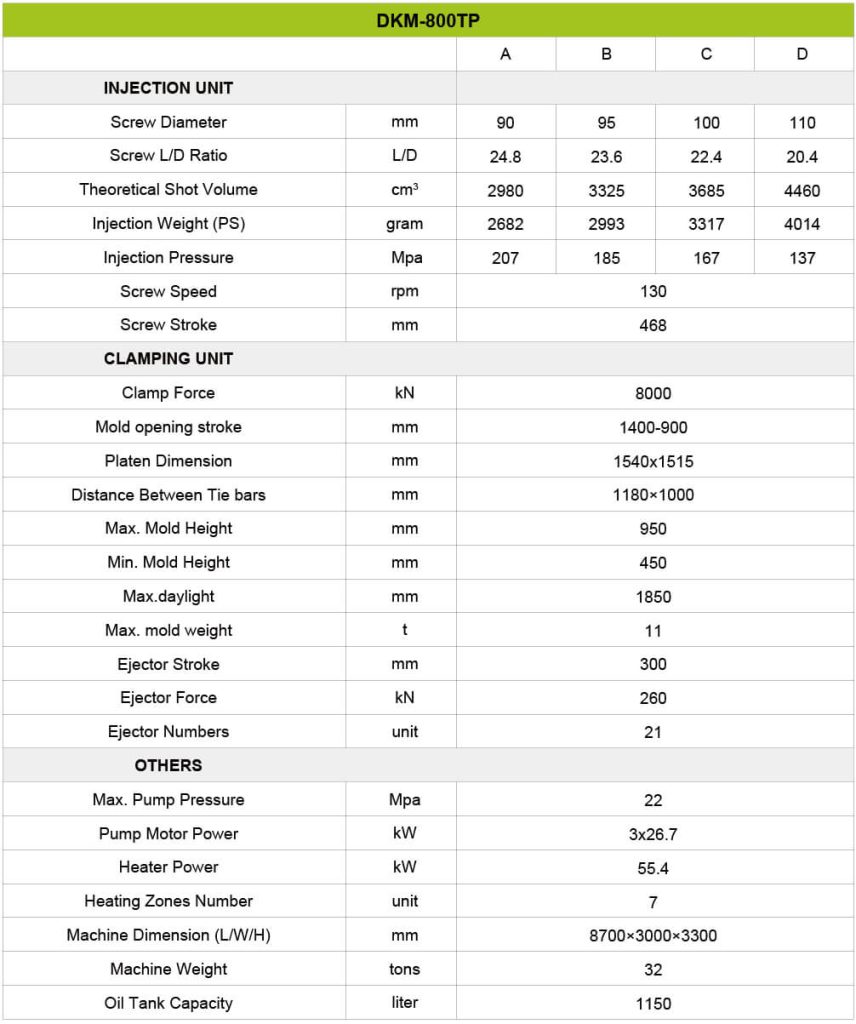

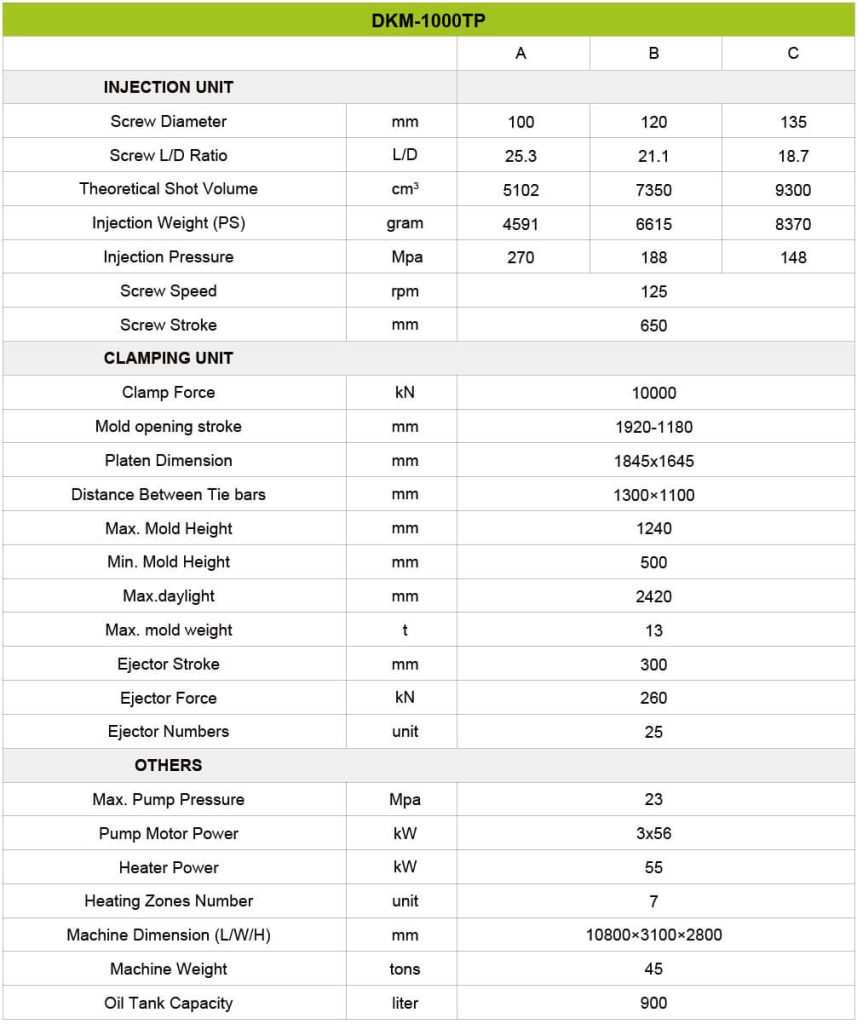

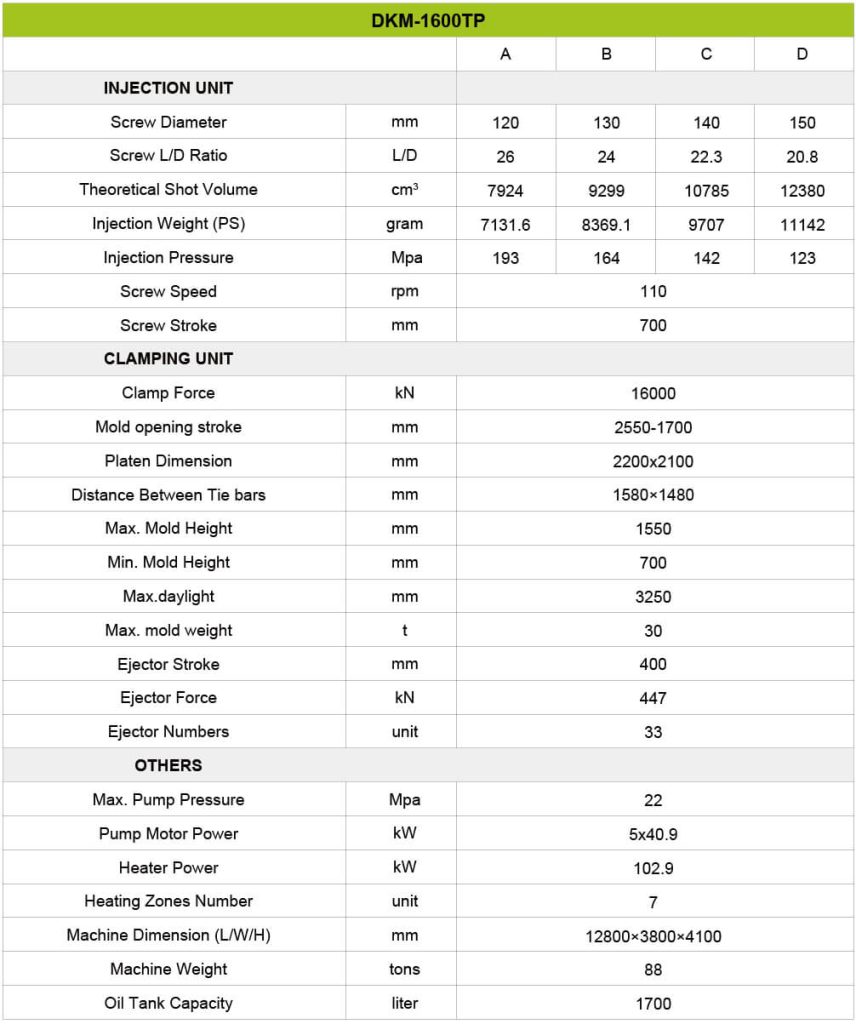

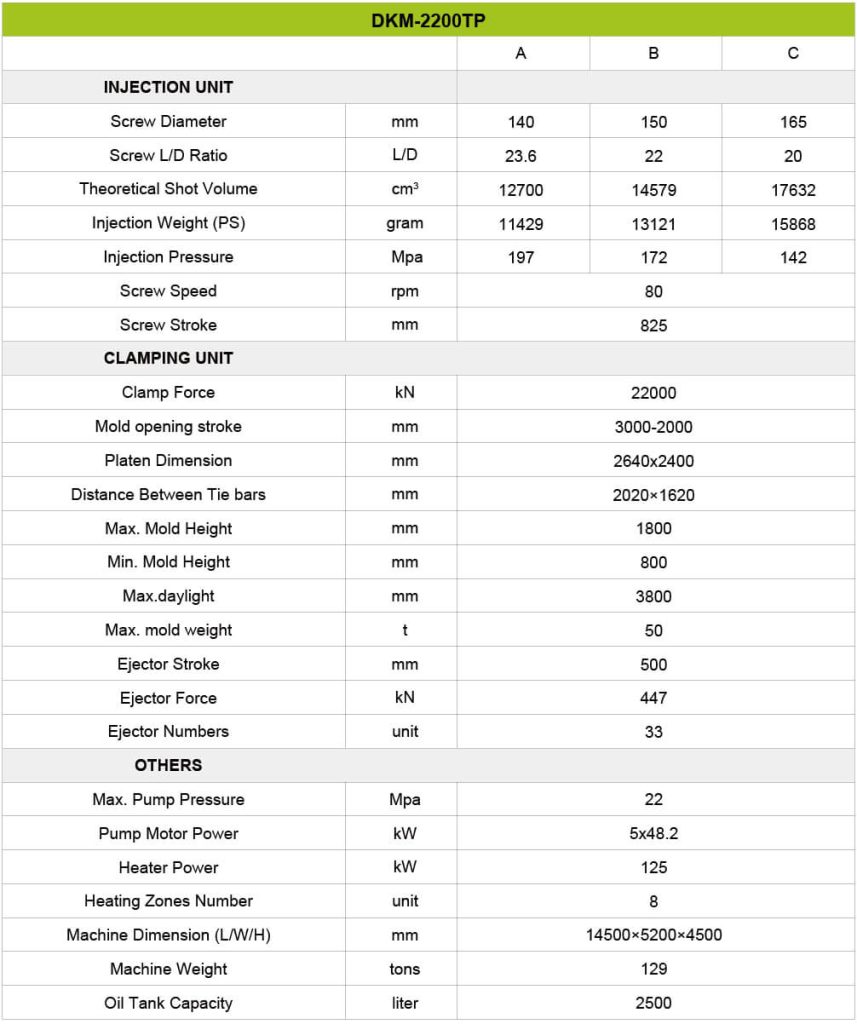

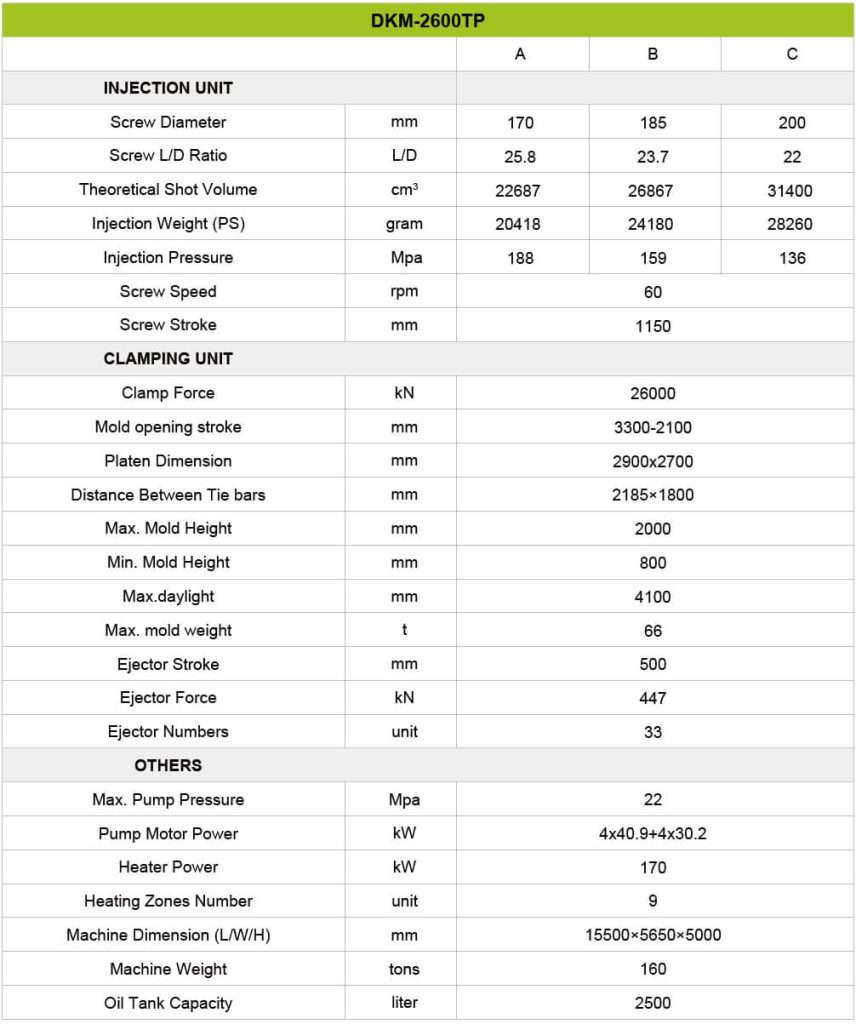

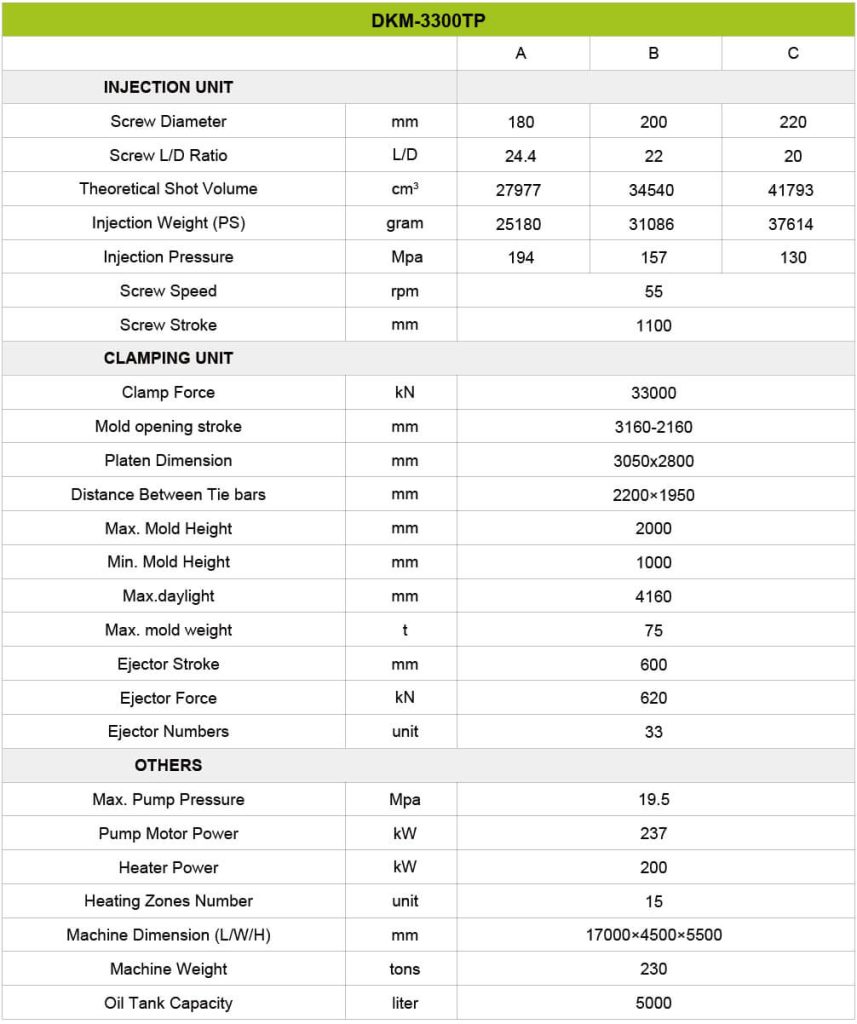

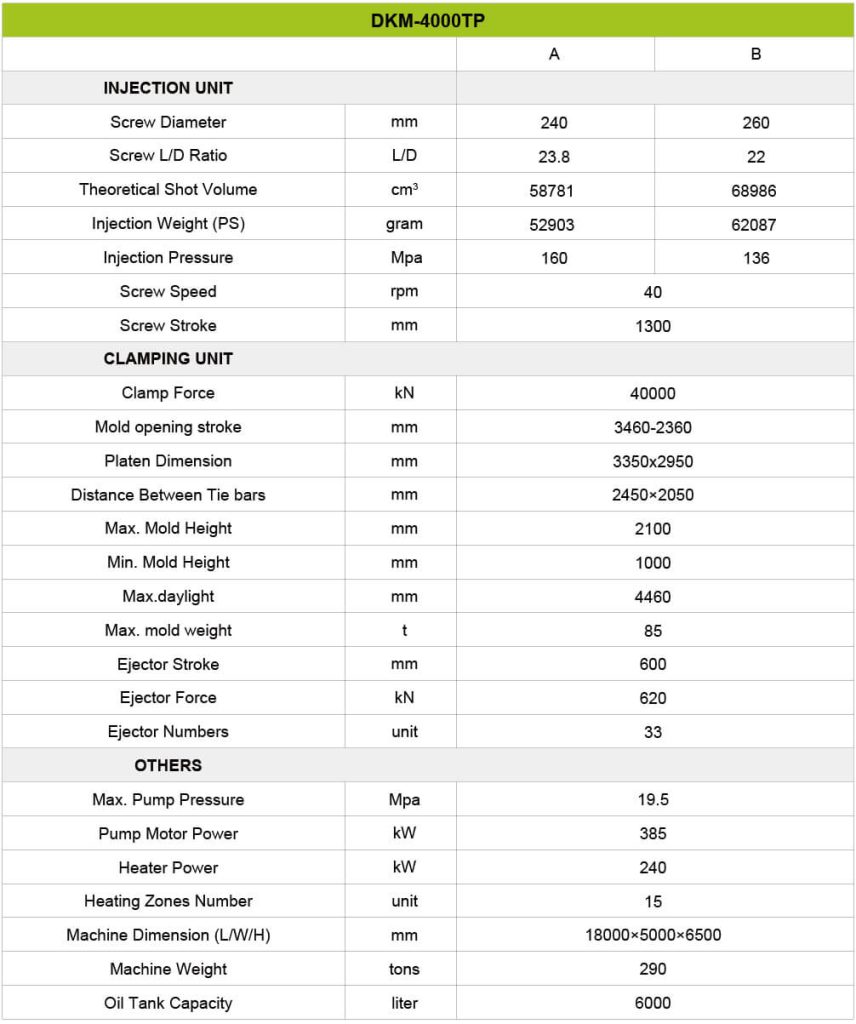

- DKM-TP Injection Molding Machine Specification

- Advantages of DKM-TP SERIES Two-Platen Injection Molding Machine:

The DKM-TP Series Two-Platen Injection Molding Machine offers several advantages compared to traditional injection molding machines. Here are some key advantages:

The two-platen design allows for faster and more efficient mold opening and closing movements. This results in shorter cycle times, increased productivity, and higher overall production output.

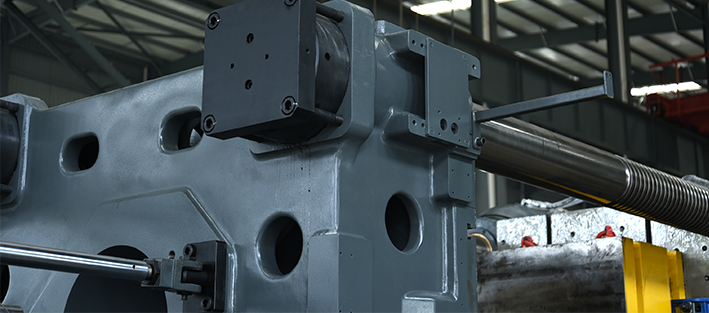

The robust construction of the two-platen machine provides increased stability during the injection molding process. This stability contributes to consistent part quality, reduced scrap rates, and improved overall process reliability.

The two-platen design of the machine helps reduce its overall footprint compared to traditional three-platen machines. This is particularly beneficial for manufacturers with limited floor space, as it allows for better space utilization and optimization of the production area.

The two-platen design offers greater flexibility in accommodating larger molds. This makes the DKM-TP Series suitable for molding larger parts or multiple smaller parts in a single mold, expanding the range of applications and production capabilities.

The incorporation of energy-saving technologies, such as servo motor-driven pumps and variable displacement pumps, improves energy efficiency. By optimizing energy consumption, the machine helps reduce operational costs and environmental impact.

The DKM-TP Series features a highly responsive servo motor system that enables precise and repeatable injection movements. This ensures consistent part quality, tight tolerances, and minimal variation in molded parts, meeting the strict requirements of various industries.

The advanced control system of the machine offers a user-friendly interface for easy operation and parameter adjustment. Operators can quickly set up and monitor the injection molding process, reducing the learning curve and minimizing downtime.

The DKM-TP Series incorporates various safety features to protect operators and prevent accidents. Safety doors, emergency stop buttons, interlocks, and fault detection systems contribute to a safe working environment.

The machine can be seamlessly integrated with auxiliary equipment and automation systems, allowing for a fully automated production line. This enhances efficiency, reduces labor costs, and improves overall productivity.

- DKM-TP Series Two-Platen Injection Molding Machine Features

DKM One Stop Solution

When it comes to injection molding machines, the Machine DKM-TP Series Two-Platen Injection Molding Machine stands out with its exceptional capabilities and advanced technology. In this guide, we will delve into the key features of this machine, including its clamping unit, machine power, and more, providing you with valuable insights into its capabilities and performance.

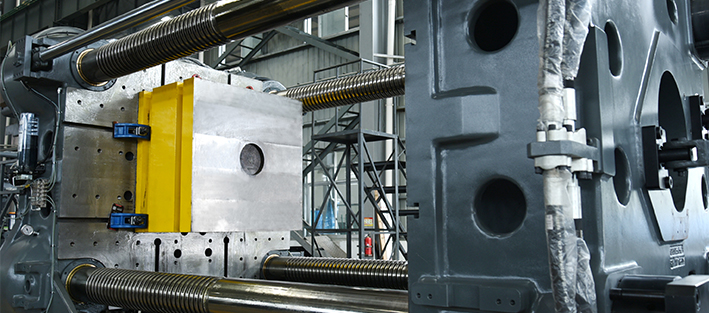

Two-Platen Design:

The DKM-TP Series features a unique two-plate design that sets it apart from traditional machines.

This design ensures superior clamping force distribution, resulting in enhanced precision and stability during the injection molding process.

The rigid and balanced structure of the machine minimizes distortion and warping, contributing to high-quality final products.

Clamping Unit:

The clamping unit of the DKM-TP Series is designed to deliver optimal performance and efficiency.

It provides precise and powerful clamping force, enabling secure and reliable mold closure.

The advanced control system allows for easy adjustment of clamping parameters, ensuring consistent and accurate results.

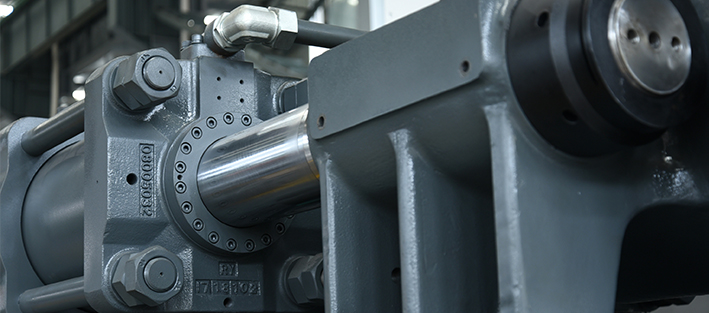

Machine Power:

The DKM-TP Series is equipped with high-performance servo motors, delivering exceptional power and energy efficiency.

These motors enable swift and precise movements, reducing cycle times and maximizing productivity.

The machine’s optimized design and intelligent control system contribute to its impressive speed and performance, making it ideal for high-volume production.

Injection Unit:

The injection unit of the DKM-TP Series is designed to meet the diverse needs of manufacturers across various industries.

It offers a wide range of injection capacities and pressures, allowing for versatility in producing both large and small plastic parts.

The precise control of injection variables such as temperature, pressure, and injection speed ensures consistent and high-quality output.

Advanced Control System:

The DKM-TP Series is designed with an advanced control system that enables operators to have complete authority over the injection molding process.

Its user-friendly interface provides effortless parameter adjustments, real-time monitoring of vital variables, and accurate control throughout the production cycle.

With advanced features like data logging and analysis, the control system facilitates process optimization, ensuring optimal efficiency and quality.

Safety Features:

Safety is a top priority, and the DKM-TP Series incorporates advanced safety features to protect both operators and the machine.

Comprehensive safety guards, emergency stop buttons, and automatic fault detection systems ensure a secure operating environment, minimizing the risk of accidents.

Why choose DKM?

DKM, a prominent manufacturer of injection molding machines, distinguishes itself in the industry not just for its outstanding machines, but also for the extensive services and support it offers to its customers. In this guide, we will showcase the unique characteristics of DKM’s services and expertise, highlighting what makes them stand out from other companies in the market.

Servo Motor Injection Molding Machines are designed to handle various types of plastics, including both commodity and engineering-grade materials. This versatility allows you to cater to diverse market demands and expand your product offerings across different industries.

These machines are built with robust construction, ensuring durability and longevity. The sturdy design can withstand the demands of high-pressure injection molding operations, reducing downtime and maintenance costs.

The machine lineup covers a broad range of tonnage options.from 80 tons to 4000 tons. This versatility allows you to selectthe appropriate machine size based on your specificproduction requirements, whether you need to produce smallcomponents orlarge-scale items.

These machines utilize advanced servo motor technologywhich provides precise and efficient operation. Servo motorsoffer excellent control over the injection process, resulting inconsistent and high-quality outputs.The dynamic control andresponsiveness of servo motors enable improved precision.repeatability.and reduced waste

Servo Motor Injection Molding Machines offer hiqh-speed injection capabilities, which contribute to improved productivityFaster injection speeds help minimize cycle times, allowing youto produce more parts in less time. This increased efficiencytranslates into higher production output and reduced costs.

Servo motor technology is known for its energy efficiency.These machines optimize power consumption by adjusting themotor speed based on the required load. They use less energyas a consequence than conventiona hydraulic svstems. whichresults in financial savings and a less environmental effect.

The high precision and reproducibility of the injection moldingprocess are made possible by the precise control provided byservo motors. This is especially important for sectors that needprecise tolerances and high-quality end products. Consistentquality output minimizes rejects and rework, leading toimproved overall efficiency and customer satisfaction.

Customized Solutions

Dakumar understands that each customer’s production needs are unique, and they offer customized solutions to meet specific requirements.

Whether it’s specialized injection units, mold clamping systems, or automation integration, Dakumar collaborates closely with customers to develop tailored solutions for optimized performance and productivity.

Advanced Technology and Innovation

Dakumar prioritizes research and development investments to integrate cutting-edge technologies into their machines. The company’s dedication to innovation guarantees that customers enjoy advanced features, enhanced efficiency, and superior product quality.

Comprehensive Customer Support

Dakumar prioritizes customer satisfaction and provides extensive support throughout the entire customer journey.

Their knowledgeable and responsive customer support team assists customers with technical queries, troubleshooting, and spare parts ordering, ensuring smooth operations and minimal downtime.

Global Presence and Distribution Network

Dakumar has a global presence, serving customers in numerous countries and regions around the world.

Their well-established distribution network enables efficient logistics, timely delivery, and prompt after-sales service, catering to customers’ needs regardless of their geographical location.

Value-Added Services

Apart from their core offerings, Dakumar provides value-added services to enhance the overall customer experience.

This includes training programmers to educate operators on machine operation and maintenance, empowering them to maximize the machine’s capabilities and minimize production risks.

Competitive Pricing

DKM offers competitive pricing for the DKM-TP series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

Provide Complete Supporting Equipment and Service for Your Injection Molding Machine

DKM One Stop Solution

24Hours Services

Training Equipment Maintenance And System Upgrade

- Conclusion:

In conclusion, Dakumar DKM-TP Series Two-Platen Injection Molding Machine proves to be a game changer in the industry. Its cutting-edge features, including the two-platen design, high-speed operation, versatility in applications, advanced control system, energy efficiency, enhanced safety features, and customization options, make it a standout choice for manufacturers. Dakumar’s commitment to providing unparalleled services, expertise, and customer support further solidifies their position as a leading manufacturer. With their extensive industry experience, global presence, and dedication to innovation, Dakumar sets itself apart from other companies by offering comprehensive solutions tailored to meet the unique needs of their customers. By choosing Dakumar, manufacturers can achieve superior quality, efficiency, and success in their injection molding processes.