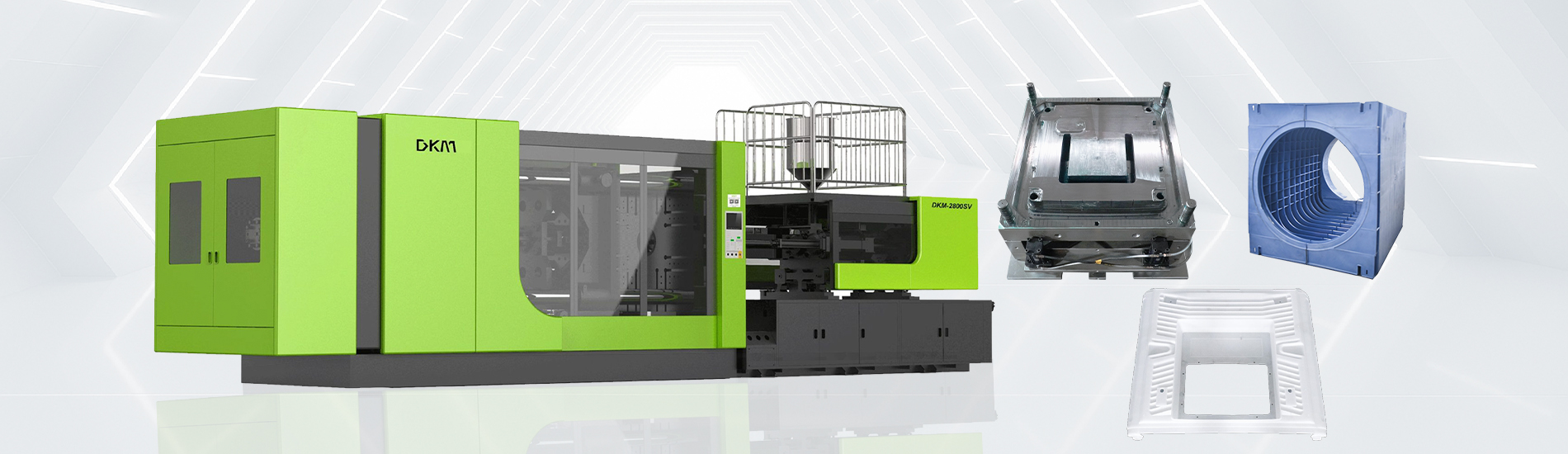

Air Cooler Housing Production Line

Designed for industrial, agricultural and commercial air cooler manufacturers, the DKM air cooler housing production line is centered on military-grade weather resistance and modular intelligent production, providing a one-stop solution from precision die-casting to surface treatment, helping to improve housing performance and reduce production costs.

Core advantages

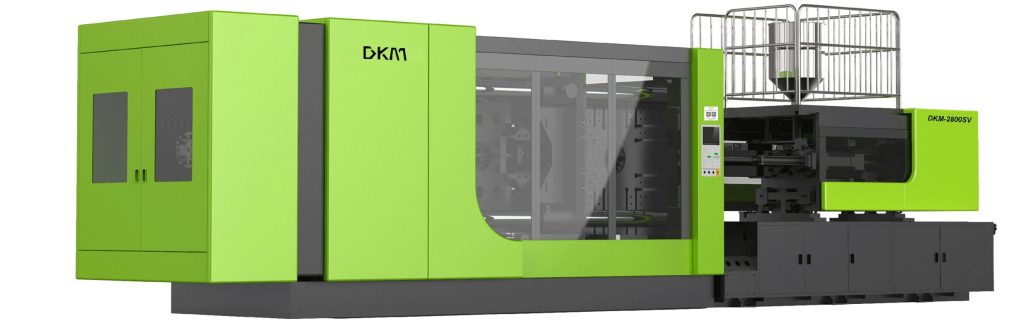

High efficiency and energy saving, leading the industry standard

- SV servo injection molding machine: using intelligent servo control system, energy consumption is reduced by 20-30% compared with traditional hydraulic presses.

- TP two-plate injection molding machine: double-plate structure design saves 30% of plant space.

- Fast cycle technology: air cooler housing production cycle is shortened by 20-30%.

Precision molding, quality assurance

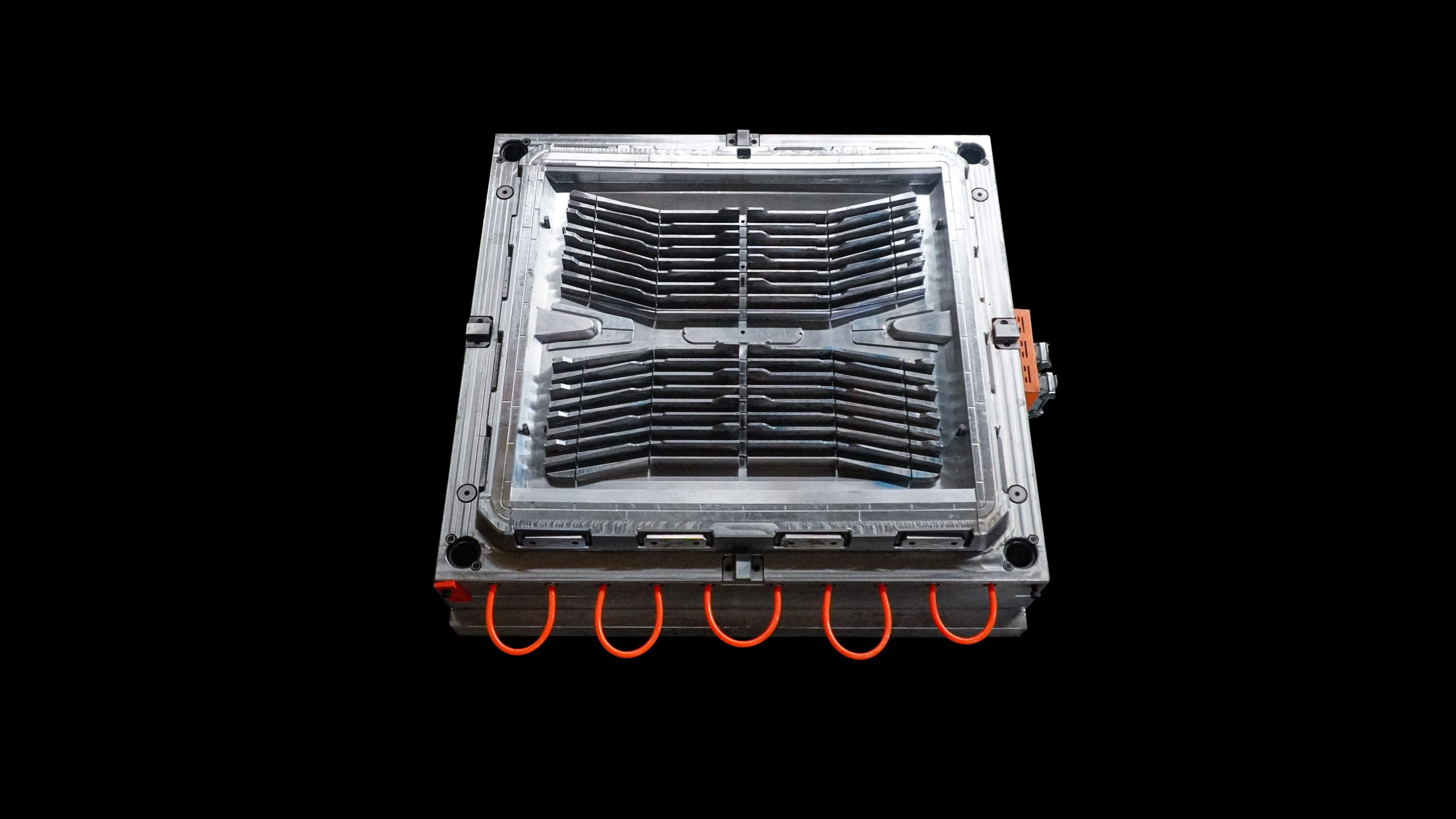

- ±0.5mm clamping accuracy (TP series composite clamping technology) ensures housing size consistency and sealing.

Air Cooler Housing Mould

high-precision mold design, adapted to complex structures (such as porous thin walls, deep barrels), compatible with industrial/commercial/home full scene needs.

Industry Applications

explosion-proof housing, compatible with compressor air coolers

integrated design of anti-corrosion mosquito filter, resistant to pesticide vapor erosion

customized matte texture/brand LOGO relief, to enhance the premium of terminal products

Customized services

Pre-embedded IoT sensor slot (temperature and humidity/vibration monitoring)

Quick-release filter buckle, maintenance time reduced by 70%

Contact us to transform your thin-wall production capabilities today.