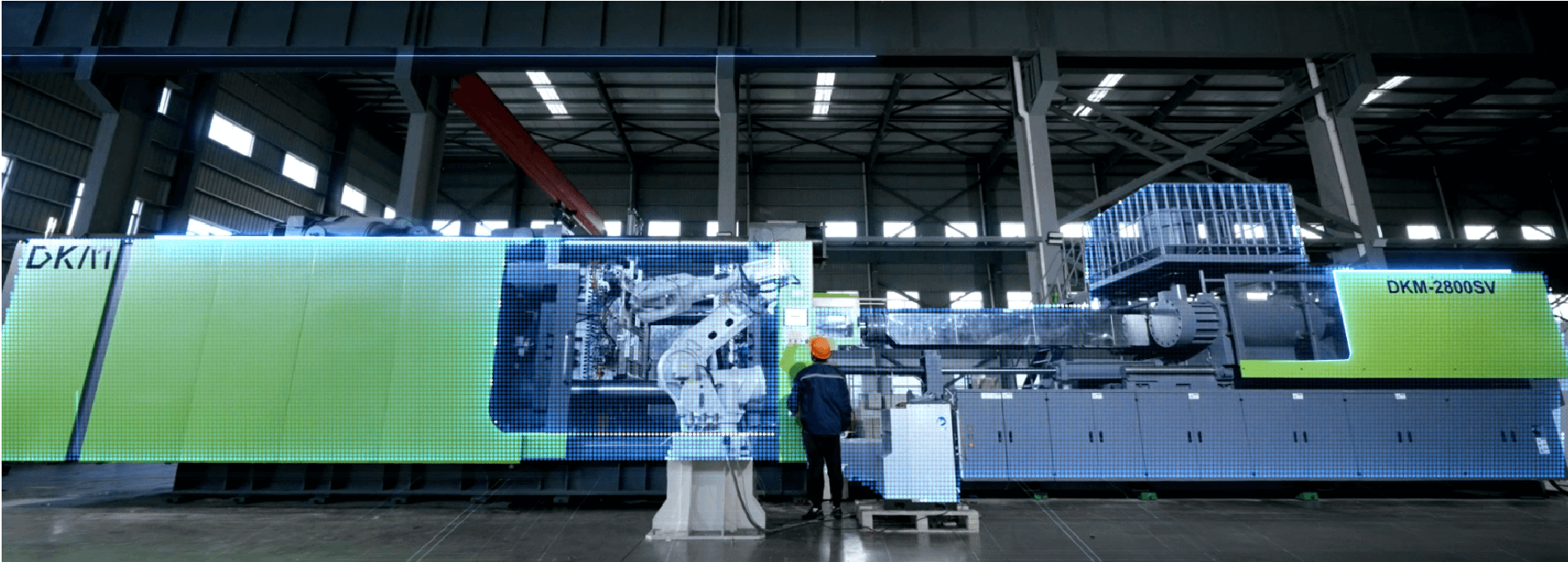

Disposable Cutlery Production Line

Core Advantages

The DKM 6th-Gen DFS Series thin-wall injection molding machine is engineered specifically for disposable cutlery (forks, knives, spoons), combining high speed, precision, and energy efficiency:

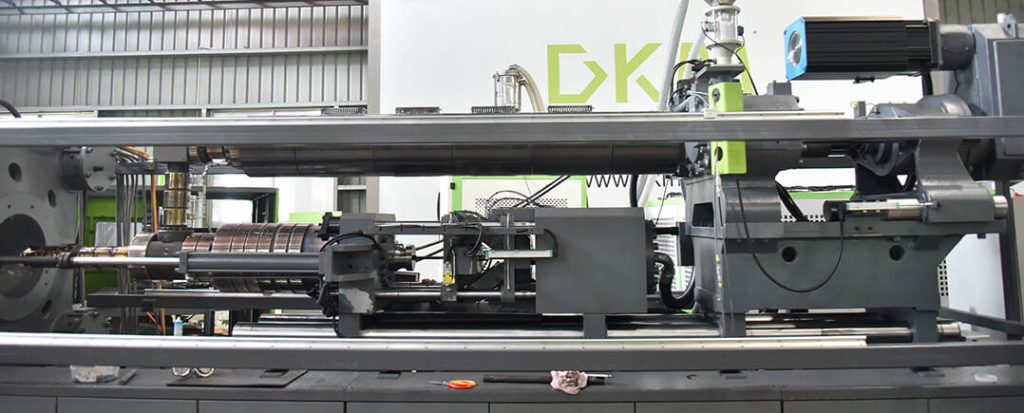

- Ultra-High-Speed Production: Maximum injection speed of 800mm/s, reducing cycle time by 30% and achieving industry-leading per-machine output.

- Precision Control: Low-inertia high-precision injection technology ensures ≤2‰ repeatability, guaranteeing dimensional consistency for every piece.

- Energy Savings: Hydraulic oil recirculation + electric pre-plasticizing system cuts energy consumption by 20%-30%.

Multi-axis synchronization shortens cycle time; 12-inch touchscreen enables one-touch operation.

Oil-leak-free design, infrared heating rings, and EU-standard connectors ensure safety, eco-friendliness, and full automation compatibility.

- High Efficiency: Multi-cavity molds (e.g., 1×8 cavities) produce multiple pieces per shot, paired with DFS high-speed machines for 5.5-second ultra-short cycles.

- Quality Assurance: High-speed CNC milling + precision cooling eliminates flash/burrs, delivering food-grade smooth surfaces.

Applications & Customer Value

Versatile Market Adaptability

- Produces disposable cutlery, food containers, etc., compatible with PP, PS, and other eco-friendly materials.

- Meets bulk-order demands from global restaurant chains, food delivery platforms, and supermarkets, helping clients seize market opportunities.

Lower Total Cost

- Easy maintenance + extended mold lifespan reduce total production costs by 15%.

- Customizable capacity/specifications to flexibly handle diverse orders.

Comprehensive Support

24/7 remote monitoring, 30+ global agents for installation, training, and after-sales service.

“Customize Your Disposable Cutlery Line Today”

- Free Proposal: Submit requirements for capacity planning & ROI analysis within 24 hours.

- Expert Collaboration: Sino Mold’s team provides end-to-end support from design to mass production.

- Turnkey Solutions: Includes auxiliary equipment and fully automated packaging lines.