Thin-Wall Packaging Box Manufacturing - One-Stop Solutions

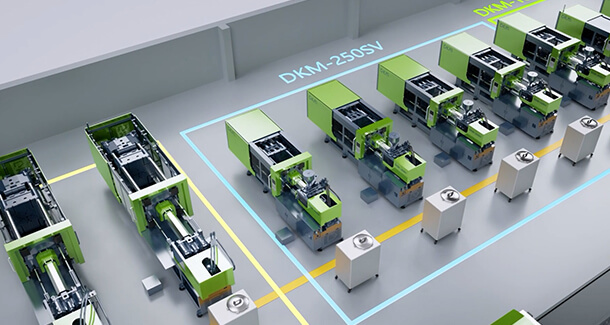

DKM offers comprehensive solutions for thin-wall box packaging injection molding, covering advanced equipment and efficient processes. A complete thin-wall box injection molding line includes high-speed machines, molds, intelligent molding systems, and conveyors, achieving automated production from raw materials to finished products, enhancing efficiency and quality, and reducing costs.

By choosing DKM’s solution, you gain not only advanced equipment and technology but also our commitment to quality and focus on customer needs.

Turnkey Solution of Thin-Wall Container Molding

- Energy-saving injection molding machine, optimized screw design, improved mixing ability, reduced energy consumption.

- Efficient injection molding solution, quick mold change, increased production efficiency.

- Offer factory layout, water-electricity-gas piping, and automation system solutions.

DFS Series Low-Inertia Thin-Wall Specialized Injection Molding Machines

01

High precision and stability: Our machines ensure high-quality and consistent thin-wall box products through precise operation and excellent stability.

02

Fast injection: An advanced system enables rapid and precise material injection, improving efficiency for large-scale production.

03

EnergyEfficiency: Energy-saving design reduces consumption and environmental impact, aligning with sustainable manufacturing requirements.

04

Advanced control system:Precise control of injection parameters ensures stable product quality.

05

Versatility:Suitable for various thin-wall box products, offering versatility and flexibility to meet different customer needs.

06

Easy maintenance:Rational design simplifies maintenance, reducing costs and downtime.

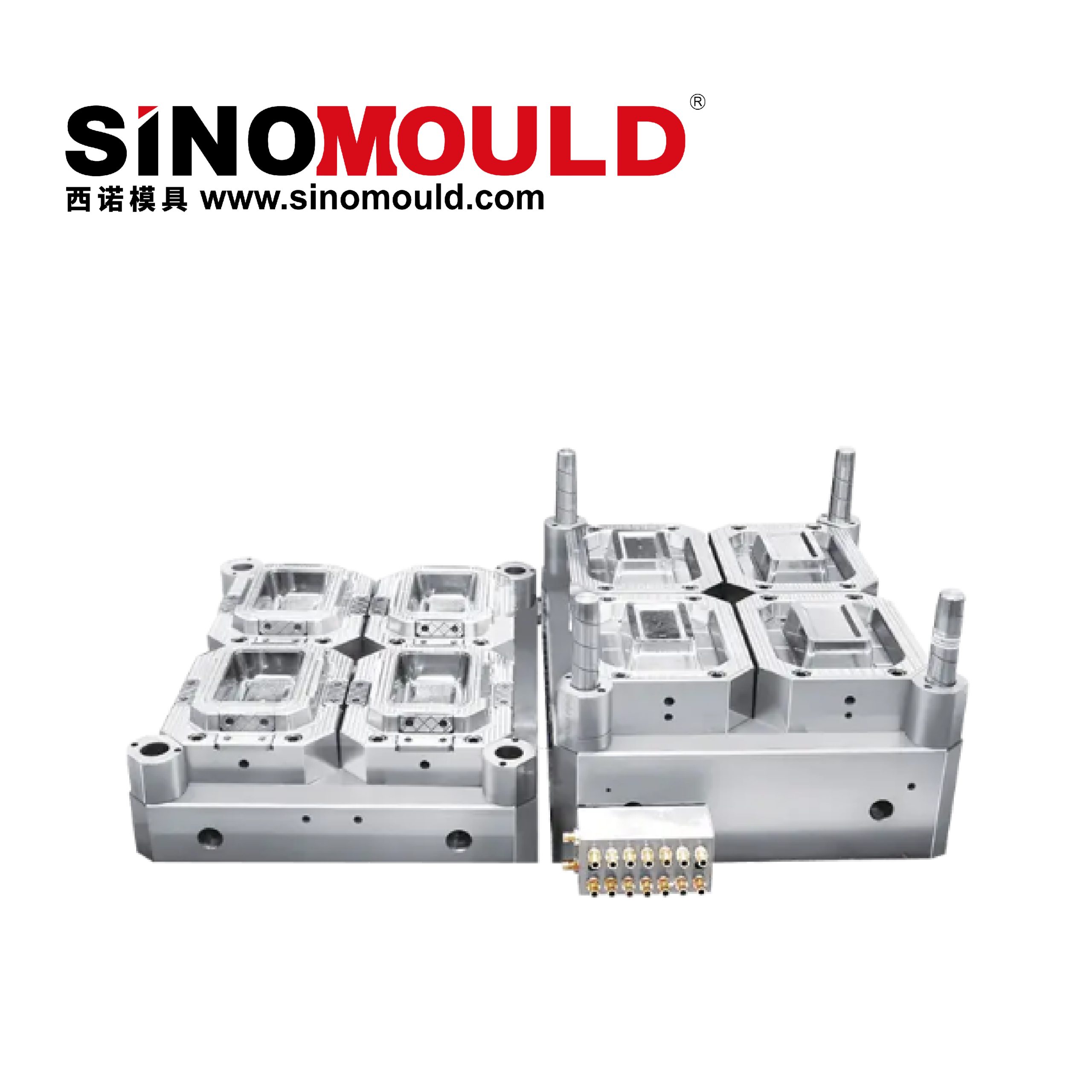

Thin-Wall Container Mould

- Made from high-quality steel with heat treatment, ensuring long life and high precision.

- Rational runner and venting system design ensures uniform plastic filling, preventing defects like bubbles and shrinkage, and enhancing product quality.

- High standard EURO standard mold frame and workmanship, with heat treatment, ensuring high strength and long life.

Auxiliary Equipment

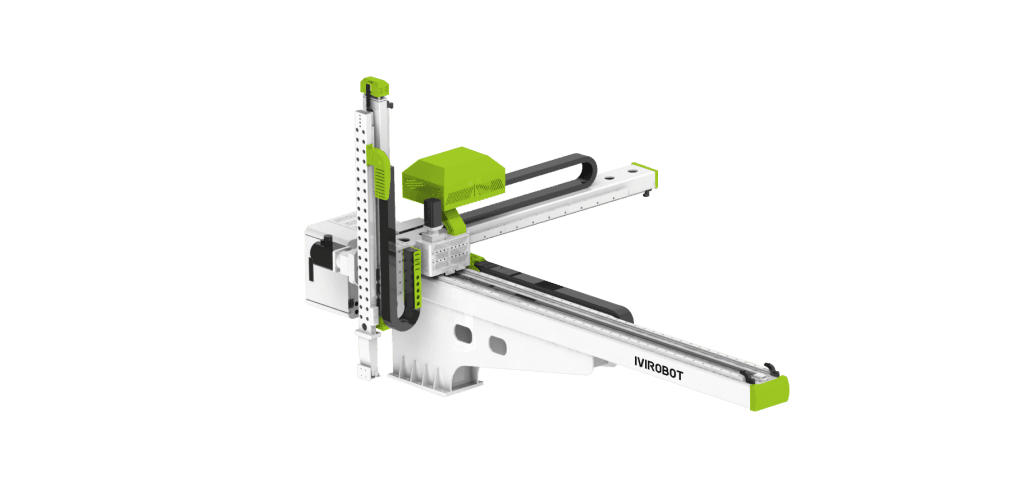

Professional and Efficient Auxiliary Equipment

Ensures smooth material flow, improving efficiency.

Provides cooling for stable operation in high temperatures.

- High speed and precision: Robots pick and place products quickly and accurately, enhancing efficiency and quality.

- 24/7 operation: Ensures round-the-clock production, reducing labor costs.

Intelligent In Mold Labeling Machine

It supports labels made of various materials such as PP, PE and PET, enables special-effect printing like laser and aluminized finishes, and balances product aesthetics with anti-counterfeiting performance.

Production Line Advantages

cycle time for 500ml containers: 5s

- In-line vision inspection (0.1mm accuracy)

- <0.3% defect rate guarantee

- Integrated robotic palletizing system

- MES-connected production monitoring

IML System(Optional Technologies)

The DKM integrated intelligent In-Mould Labelling (IML) system seamlessly incorporates the decoration process into the injection molding cycle, creating flawless, durable, and instantly molded high-value-added products for you, completely eliminating the need for secondary labeling.

1. Ultra-High-Speed, High-Precision Robot

Specifically designed for the rapid cycles of thin-wall packaging, with meticulously optimized label pick-and-place times.

Achieves a repeat positioning accuracy of ±0.1mm, ensuring the absolute positional accuracy of every label within the mold cavity.

2. Intelligent Label Management and Feeding System

Integrated hopper-type or reel-to-reel feeding devices adapt to different requirements for sheet labels and roll labels.

Features automatic dust removal and static elimination functions to ensure labels are clean and flat.

An optional vision inspection system enables 100% rejection of defective/missing labels, guaranteeing high yield rates.

Multiple service centers worldwide for timely professional support.

We commit to swift production and delivery, enabling prompt customer production.

Our engineers install, commission equipment, and provide training for smooth customer start-up.

- Choose DKM for more than advanced equipment

gain a strategic partnership dedicated to your thin-wall production success. Our solutions combine German engineering precision with localized service excellence, delivering measurable ROI through:

- 98.5% equipment uptime guarantee

- 30% faster time-to-market

- Lifetime technical suppor

Contact us to transform your thin-wall production capabilities today.