Spring Bottle Cap Production Line

Transform your packaging with our next-generation Spring Bottle Cap Production Line, engineered for high-speed manufacturing of caps that combine functionality, durability, and user-centric design. Ideal for industries demanding seamless access and airtight security, our line delivers flawless spring mechanisms and unmatched consistency for caps that elevate your product experience.

Why Our Spring Cap Line Stands Out

Ultra-Fast Spring Integration

Achieve 5s cycle time with precision-assembled spring systems, ensuring smooth actuation and reliable performance.

Zero-Leak Guarantee

Advanced sealing technology and pressure-testing modules ensure 100% airtight closures, critical for carbonated beverages, pharmaceuticals, and liquids.

Ergonomic Design Flexibility

Produce caps with push-down, twist-release, or flip-top spring mechanisms in materials like PP, PET, or metal alloys.

Smart Automation

Robotic spring insertion, torque calibration, and real-time defect removal minimize waste and maximize uptime.

Rigorous Quality Assurance

AI-powered inspection for spring tension, alignment, and surface integrity – every cap meets ISO standards.

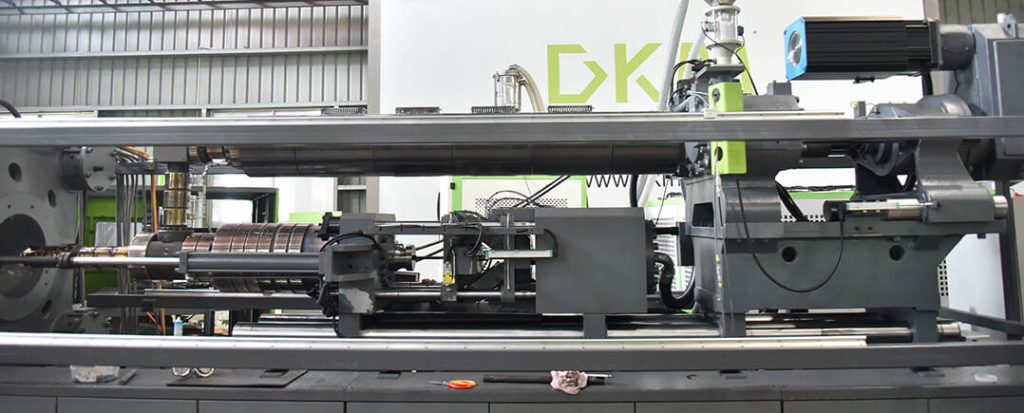

Core Components & Technology

Simulates 10,000+ open/close cycles to validate longevity.

Custom logos, batch codes, or safety indicators applied inline.

Monitor spring tension, cap torque, and production metrics in real time.

Industry Applications

- Carbonated Drinks: Tamper-evident spring caps for soda bottles.

- Premium Cosmetics: Luxury push-button dispensers for serums and creams.

- Pharmaceuticals: Child-resistant closures with smooth spring action.

- Household Chemicals: Leakproof caps for detergents and sprays.

- Food & Beverage: Easy-open caps for condiments and ready-to-drink products.

Your Advantage, Our Commitment

Tailored Solutions

Adapt spring mechanisms, cap sizes, and automation levels to your product needs.

Global Expertise

20+ years in cap manufacturing, with on-site engineering support worldwide.

Future-Ready Upgrades

Modular design allows integration of new materials or smart cap technologies (e.g., NFC-enabled).

FAQ Section

Q: Can the line handle caps with integrated RFID tags?

A: Yes! Our modular design supports smart cap integration.

Q: What’s the lead time for a customized line?

A: Typically 1 months, depending on configuration.

Request a Consultation Today!

Unlock the potential of spring caps with a line built for precision, speed, and scalability.